High-luminous-intensity light source microscope and image identifying and analyzing device and application

A technology of luminous intensity, identification and analysis, applied in microscopes, material analysis by optical means, measurement devices, etc., can solve the problems of poor fiber surface structure resolution, difficult to identify fiber surface structure and morphology, and insufficient imaging clarity. Achieve the effect of improving the ability of microscopy to identify and measure, avoid measurement errors, and improve imaging clarity and light transmission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

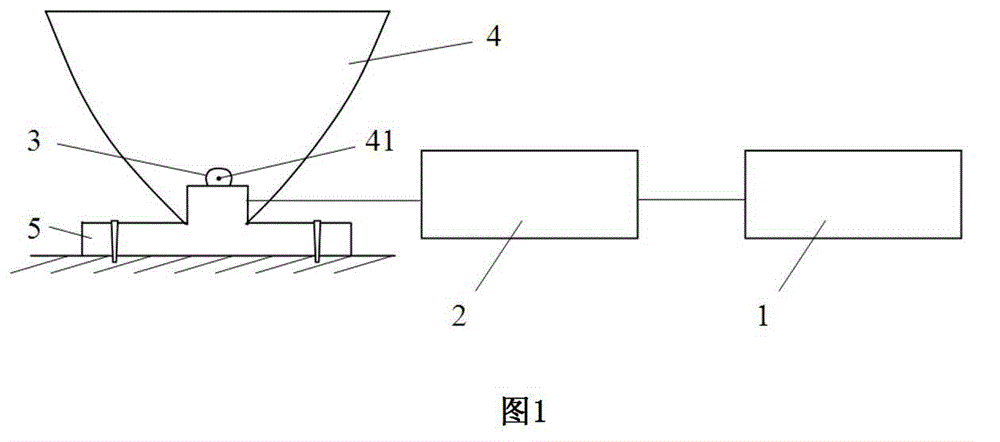

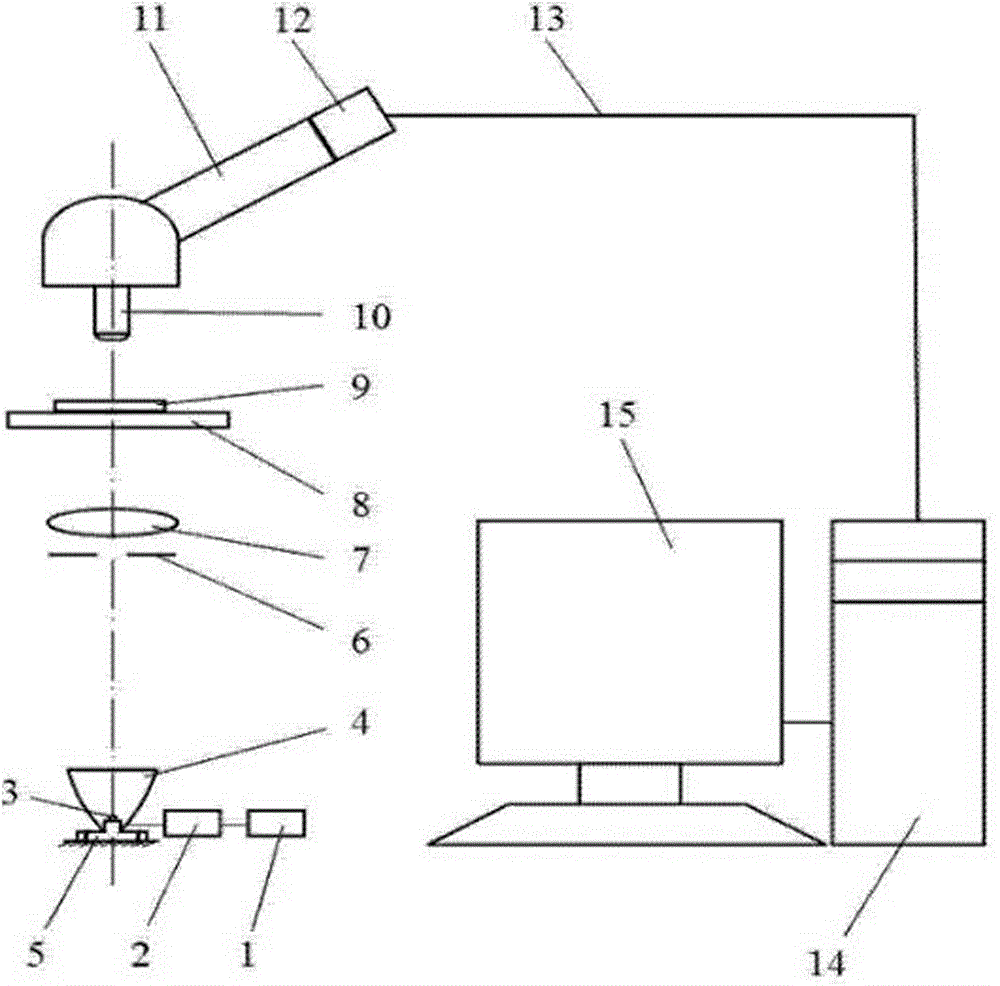

[0029] see figure 1 -2. The present invention discloses a high luminous intensity light source microscope image identification and analysis device. like figure 1 As shown, the main innovation of the present invention is: the built-in high luminous intensity LED light collecting light source device included in the microscope; the built-in high luminous intensity LED light collecting light source device includes a power supply 1, a brightness adjuster 2, a built-in high luminous intensity LED The light source 3, the light collecting cover 4, the lamp holder 5, and the built-in high luminous intensity LED light source 3 are located at the light collecting focus 41 on the center line of the light collecting cover 4, and are fixed in the inner base of the microscope through the lamp holder 5, and the light emitted by it passes through The light-collecting cover 4 generates beams of parallel light; the light intensity of the built-in high-luminous-intensity LED light source 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com