Spiral and stacked packing device of balancing chain for elevator balance chain packing equipment

A technology of balancing chain and chain packing, which is applied in the direction of packaging, transportation and packaging, single objects, etc., and can solve the problems of manual assistance workload and work intensity, and not meeting the requirements of high-quality balanced chain packing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

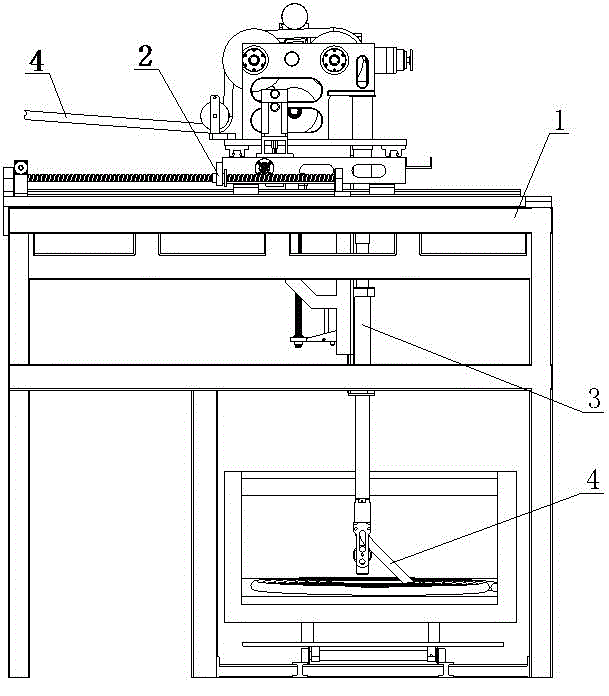

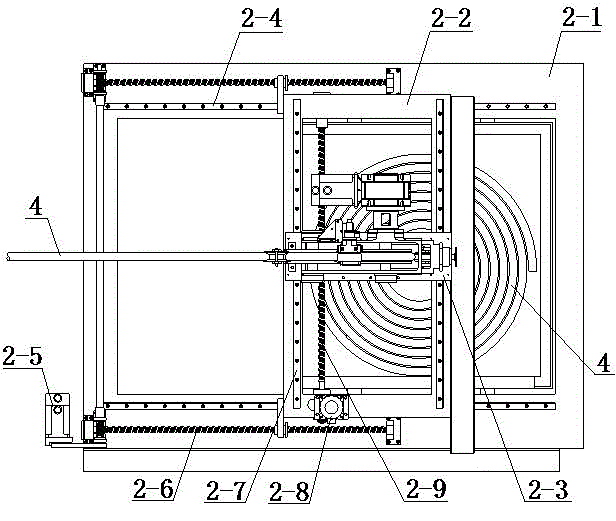

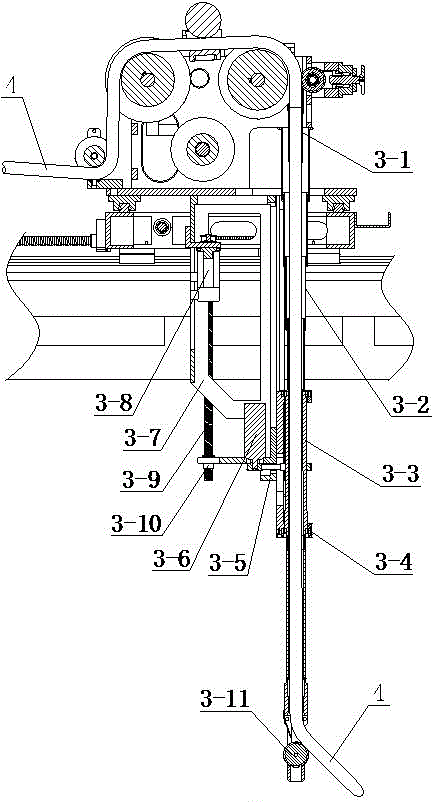

[0013] A spiral stacked packing device for balance chains used in elevator balance chain packing equipment, such as Figure 1 to Figure 3 As shown, it consists of a frame 1, a balance chain spiral track feeding mechanism 2 and a balance chain vertical follow-up guide feeding mechanism 3. The balance chain spiral track feeding mechanism 2 includes a frame-type fixed seat 2-1 and a frame-type sliding seat 2 -2 and the balance chain delivery slide seat 2-3, the first guide rail group 2-4 and the first screw mandrel group 2-6 driven by the first servo motor 2-5 are arranged on the frame type fixed seat 2-1 On the one hand, the frame slide 2-2 is slidably erected on the first guide rail group 2-4, on the one hand, it is fixedly connected with the screw nut of the first screw set 2-6, and on the frame slide 2-2 The second guide rail group 2-7 and the second screw rod group 2-9 driven by the second servo motor 2-8 are arranged on the top, and the balance chain delivery slide seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com