Method for monitoring urea quality of an scr system

A technology of SCR system and urea, which is applied in the direction of diagnostic devices, instruments, and indirect flow characteristic measurement of exhaust gas treatment devices, and can solve problems such as increasing the overall cost of the SCR system, difficult to arrange and use sensors, and significant packaging space for sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

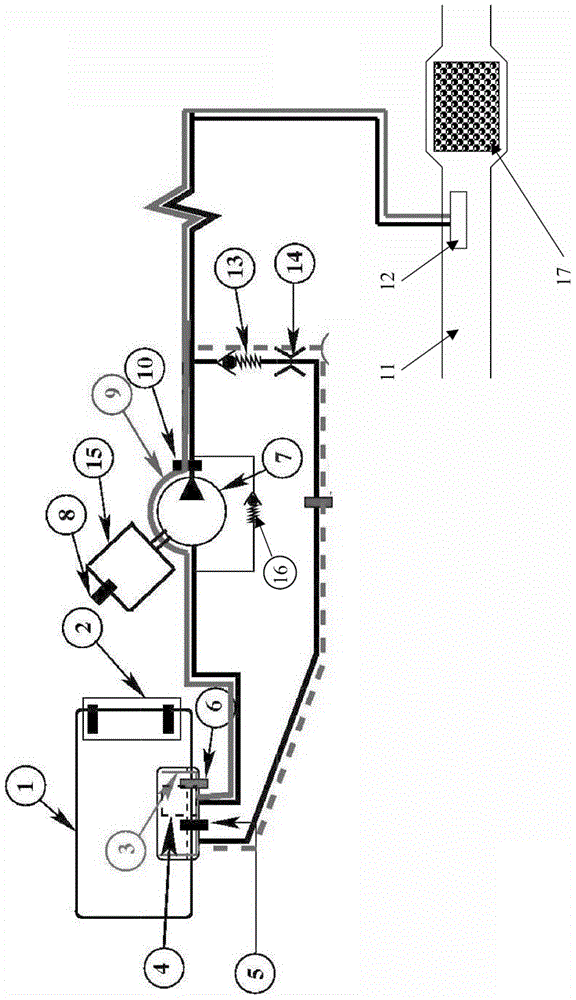

[0048] exist Figure 1 to Figure 5 The same reference numerals are used in , respectively, to denote the same elements (or functionally similar elements).

[0049] figure 1 A specific embodiment of an SCR system to which the present invention may be applied is shown.

[0050] The SCR system comprises a urea tank 1 containing a urea solution. The urea storage tank 1 is equipped with the following components:

[0051] - Gauge 2 (i.e. liquid level sensor);

[0052] - heating element 3;

[0053] -filter4;

[0054] - temperature sensor 5; and

[0055] - Current sensor 6 for the heating element.

[0056] The urea solution is delivered by the action of the pump 7 to an injection device 12 located upstream of the SCR catalyst 17 in the line 11 for exhausting the vehicle's engine. The pump 7 is driven by a BLDC motor 15, controlled by a controller (not shown). The controller is able to receive the signal measured by the pressure sensor 10 (which relates to the output pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com