Air purification device with water spraying as main part and semiconductor refrigeration thermal effect as auxiliary part

A technology of air purification and semiconductor, applied in the field of air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

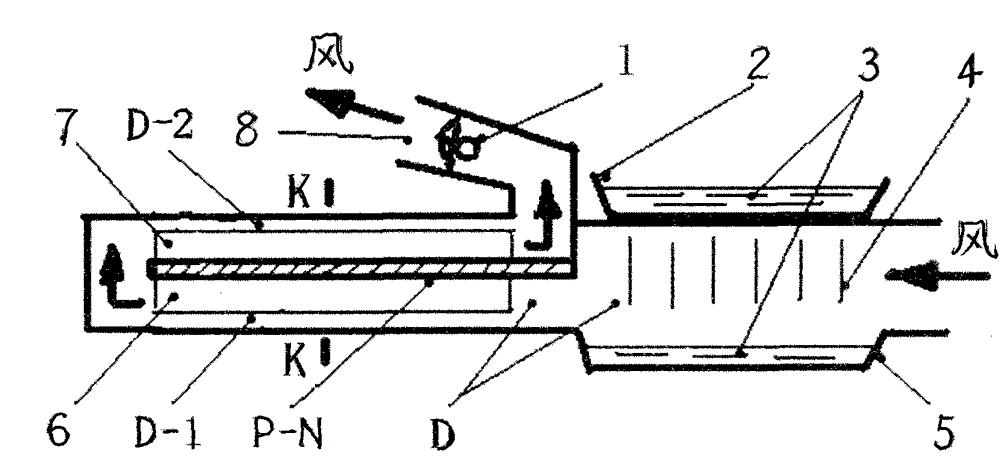

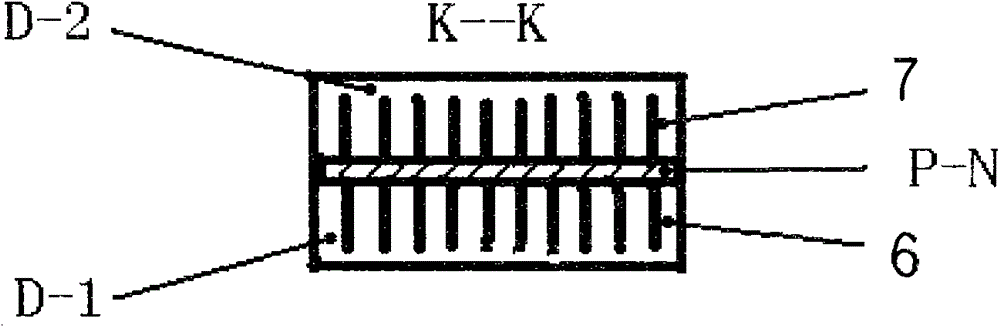

[0022] Well-known common sense: as long as direct current is passed through the "P-N" junction semiconductor device P-N, the cooling effect and heating effect can be generated on its front and back sides respectively. The core of the present invention is based on the two The key feature that the side of the direct current power supply can produce cooling effect and heating effect respectively at the same time leads to the idea of realizing the solution of the present invention with the smallest device volume and substantial energy saving effect.

[0023] Note: the application of "P-N" junction semiconductor device P-N in refrigeration engineering (its heat production is abandoned) or heating engineering (its cold production is abandoned) is a very mature matter, so the thermodynamic calculation problem involved in the present invention is here omitted.

[0024] The air purification level that the present invention intends to realize should be the highest, and this just must ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com