Heat-dissipation dry type transformer device

A technology for dry-type transformers and shells, which is applied in the field of transformers, and can solve problems such as equipment safety risks, overheating, and safe operation, and achieve the effects of reducing local overheating areas, compact equipment structure, and improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

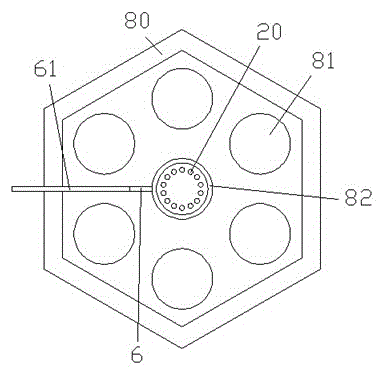

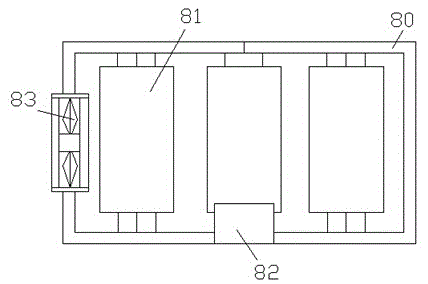

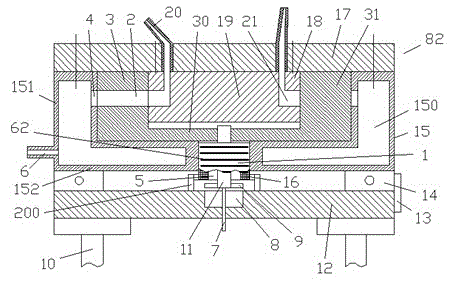

[0010] Combine below Figure 1-3 The present invention will be described in detail.

[0011] A heat-dissipating dry-type transformer device according to an embodiment includes a housing 80 provided with a cooling exhaust fan 83 on the side wall and a plurality of winding columns 81 arranged uniformly in the circumferential direction in the housing 80, wherein, The bottom of the central part surrounded by the plurality of winding columns 81 is provided with a cooling blowing device 82 supplied with air from the gas delivery pipe 61, and the cooling blowing device 82 includes a gas inlet nozzle 6 to communicate with the gas delivery. The air cavity annular shell 15 connected by the tube 61, the air cavity annular shell 15 is integrally provided with the bottom annular portion 152 and the upper cylindrical portion 151 and the inside is a gas communication cavity 150, the cylindrical The inner side wall of the part 151 is provided with a plurality of communication holes 4 evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com