LED filament lamp and its assembly method

A technology for LED filament lamps and lamp holders, which can be applied to lampshades, lighting devices, and components of lighting devices. It can solve problems such as damage to LED light strips, achieve good shock absorption effects, reduce parts, and accurately distribute positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

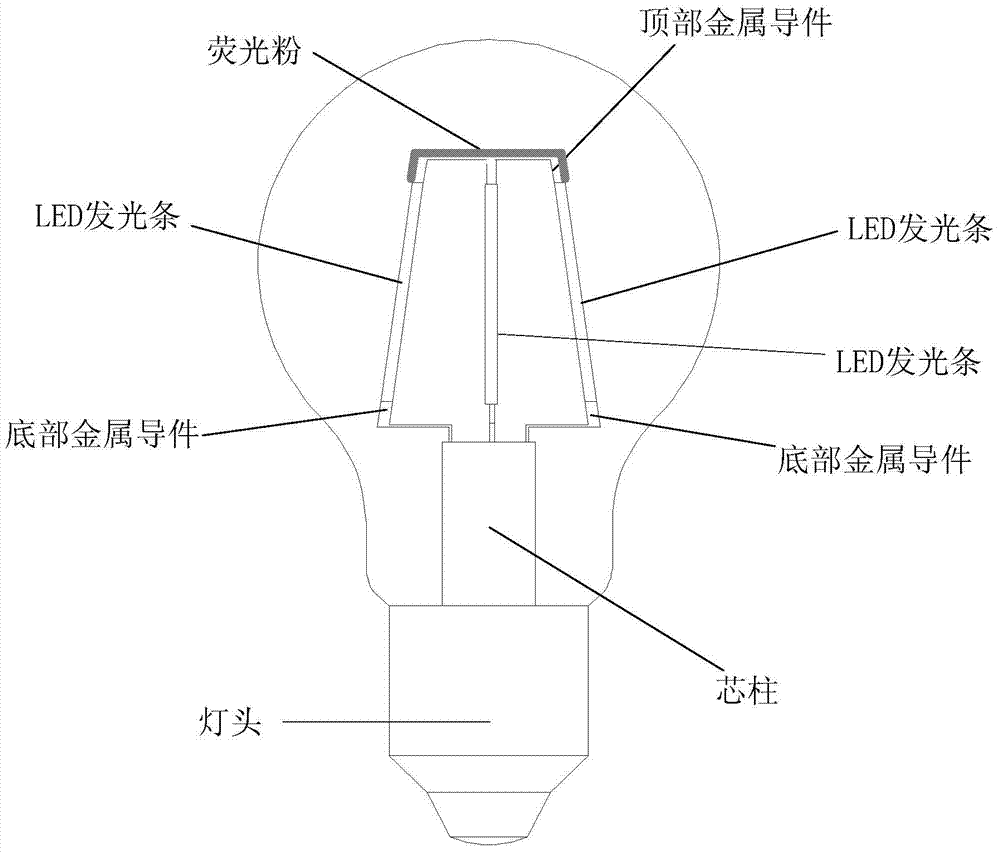

[0025] The following will combine figure 1 The LED filament lamp and assembly method provided by the present invention are described in detail, which is an optional embodiment of the present invention, and it can be considered that those skilled in the art can carry out the Modify and polish.

[0026] Please refer to figure 1 , the present invention provides an LED filament lamp, comprising a core column and several LED light-emitting strips, the core column is conductively connected to one end of each LED light-emitting strip through a metal guide at the bottom, and one end of each LED light-emitting strip is Supported by the bottom metal guide.

[0027] The present invention adopts the metal guide at the bottom to provide support and conduction for one end of each LED light strip, so that the installation of the LED light strip is firmer, and it is possible to get rid of the design of the glass column. On this basis, it will inevitably bring The bottom metal guide exposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com