Automatic bag-changing, deodorizing and detecting garbage can

A garbage can, automatic technology, applied in the direction of garbage cans, garbage collection, garbage cleaning, etc., can solve the problems of automatic deodorization and ventilation of garbage cans, bad health effects of replacement personnel, and inability to detect the amount of garbage in the bucket, etc., to achieve Solve the problem of odor generation, simple structure, prevent bacteria and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

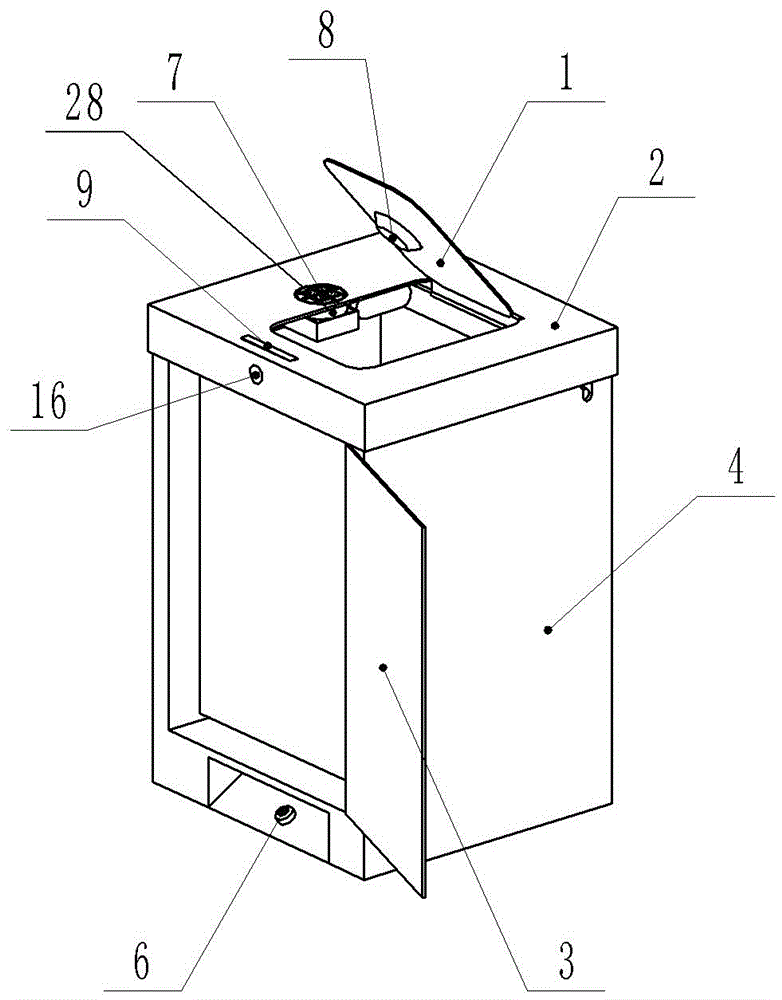

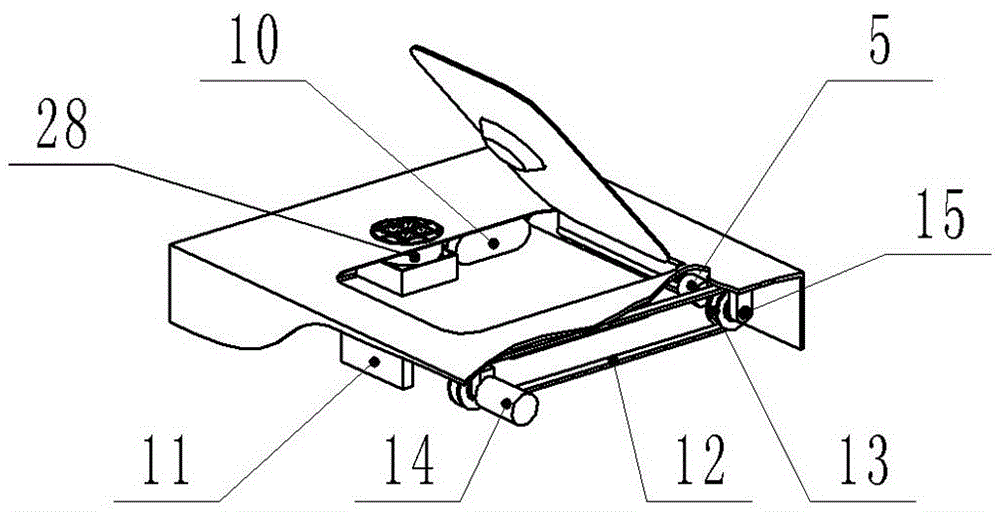

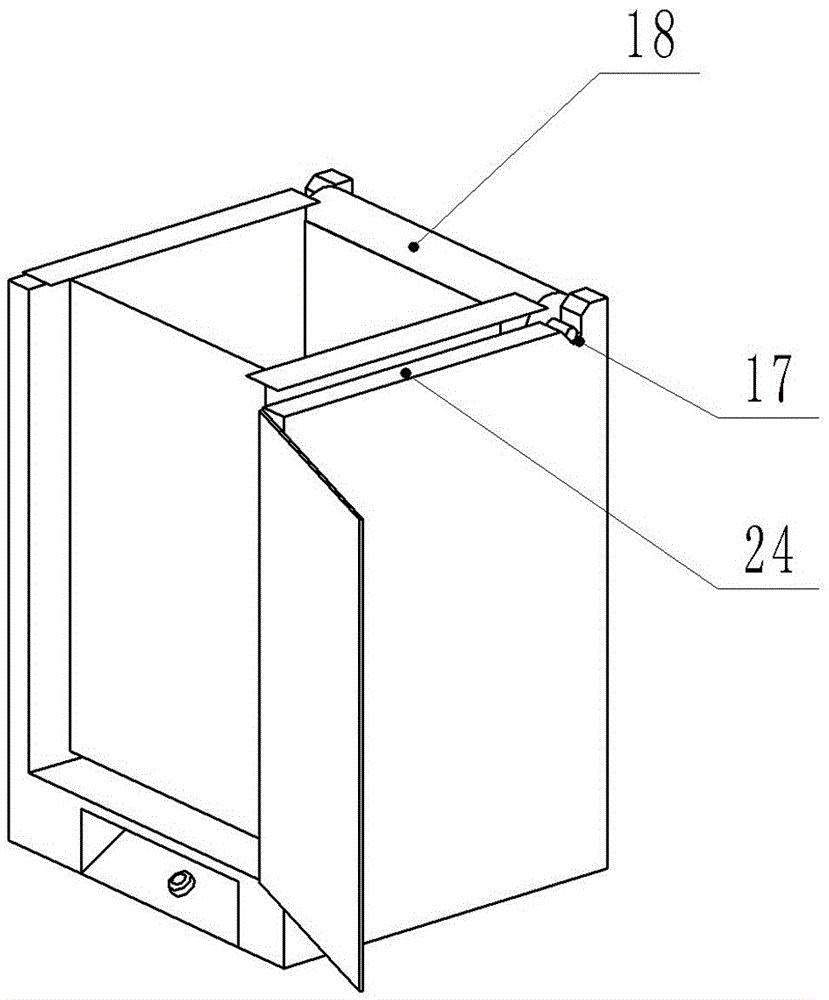

[0027] figure 1 , figure 2 with image 3 The trash can, it comprises the bucket body 4 that is provided with garbage drop-in opening on the top, bucket lid seat 2, and the bucket lid 1 hinged with bucket lid seat, bucket lid seat 2 covers are placed on bucket body 4, and the front of bucket body 4 is arranged There are front door 3 and a bung switch 6 for controlling the opening and closing of bung 1. Garbage bag slideways 24 are arranged on the left and right sides above the bung body 4; Ultrasonic ranging unit 8, display lamp 9, ventilation duct 28, fan, bag changing switch 16, control module 10 and battery pack 11; garbage bag driving mechanism is arranged on both sides of bung seat 2, and this driving mechanism includes four synchronous Wheel 13, synchronous wheel 13 is installed on the bung seat 2 by hinge shaft 15, and wherein a synchronous whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com