Automatic bag replacement and edge rolling garbage can

A trash can and automatic technology, applied in the field of trash cans, can solve problems such as troublesome operation, easy direct contact with garbage, and adverse effects on the body of replacement personnel, saving time, improving life efficiency and quality of life, and eliminating the need for manual bag placement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

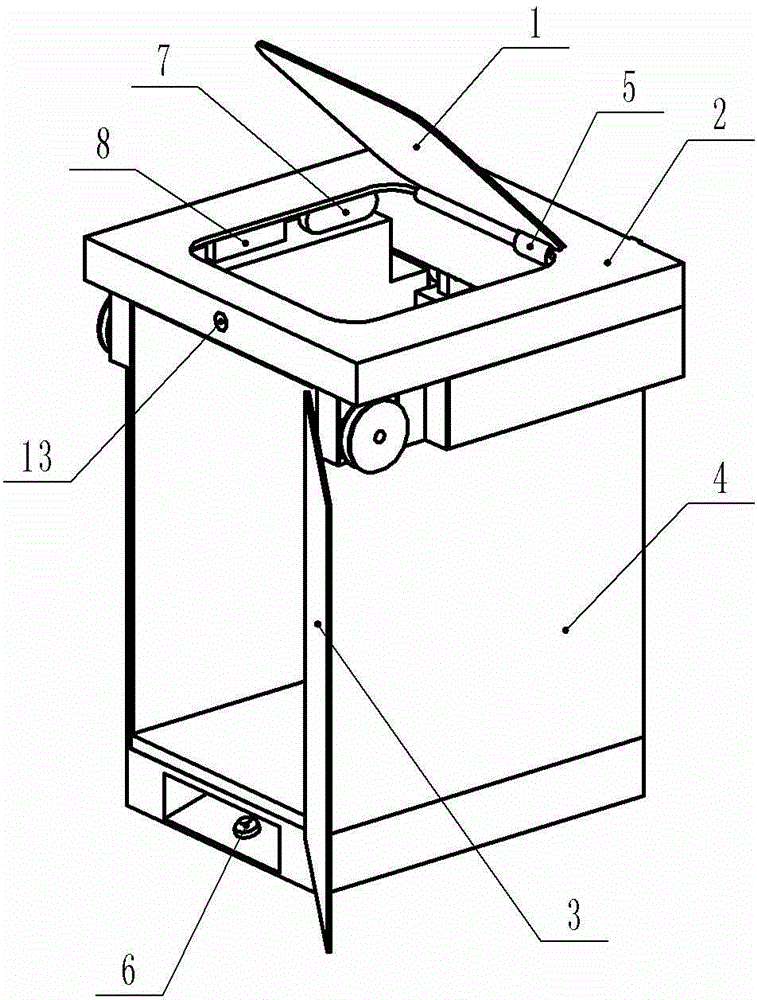

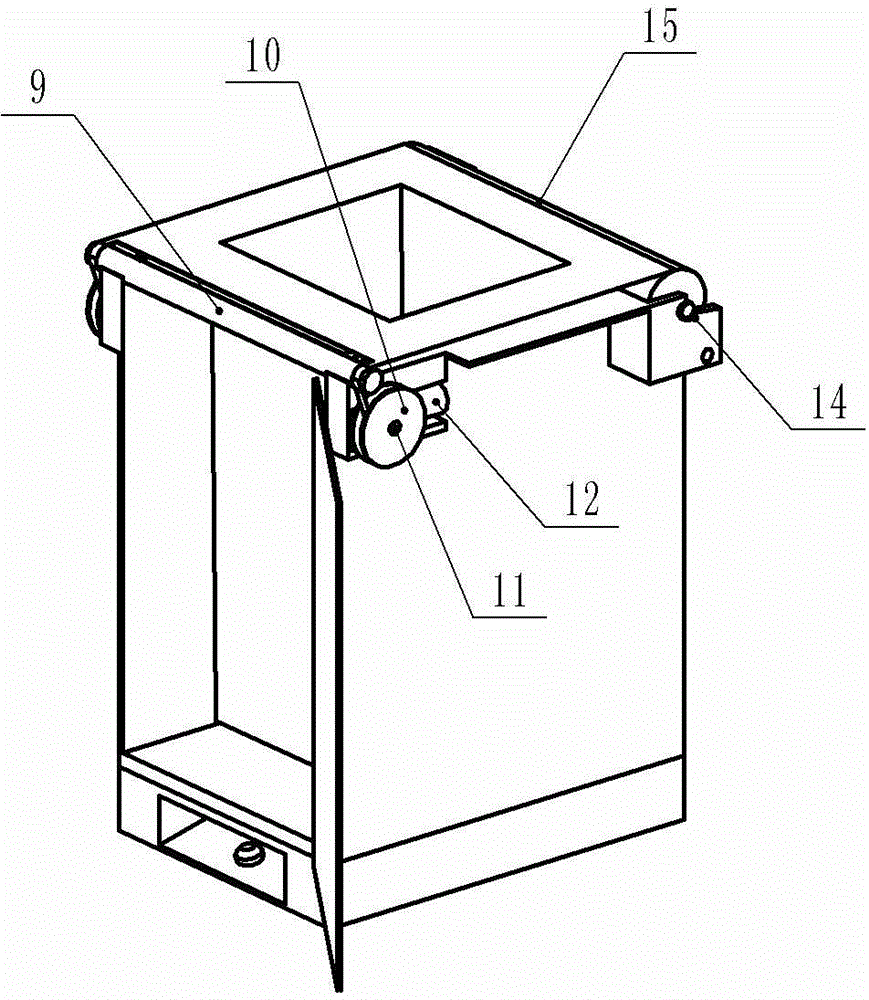

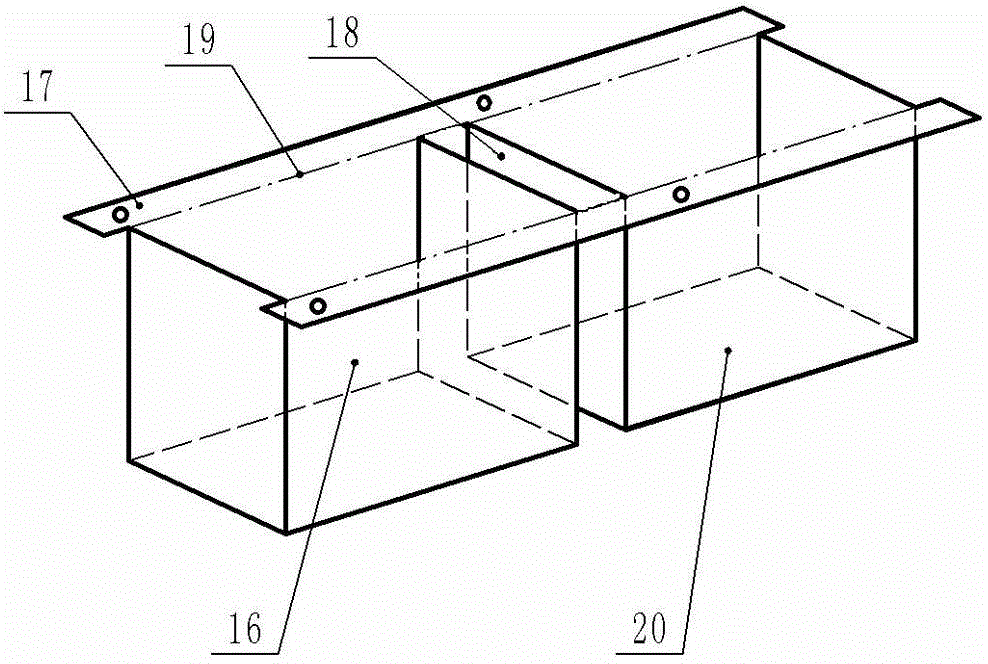

[0019] figure 1 and figure 2 Shown dustbin, it comprises that the upper part is provided with the staving 4 of rubbish drop opening, bung seat 2, and the bung 1 that bung 2 seats are hinged, and bung seat 2 covers are placed on staving 4, and staving 4 The front of the front door is provided with a front door 3 and a bung switch 6 for controlling the opening and closing of the bung lid 1. Garbage bag supporting mobile devices are arranged on the left and right sides above the bucket body 4. Wheel 10, take-up wheel rotating shaft 11 and the bag-changing motor 12 that drives the take-up wheel, on the main door frame above the take-up wheel 10, are provided with guide belt column 9, and the side of barrel inner cavity opposite with guide belt column 9 is provided with There is support groove 14, and support groove 14 is used for laying the garbage bag ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com