Automatic bag replacement, deodorization, detection and disinfection garbage can

A trash can, automatic technology, used in trash cans, garbage collection, household appliances, etc., can solve problems such as disease, environmental pollution, troublesome operation, etc., to prevent bacteria and odors, improve life efficiency, and protect the effect of environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

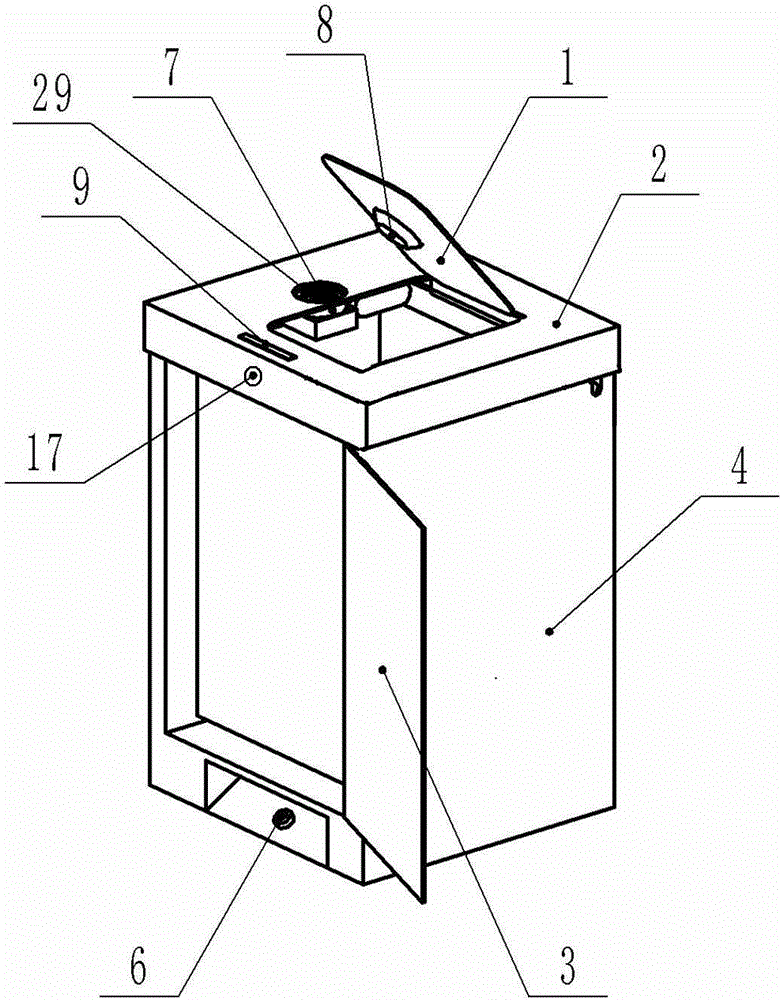

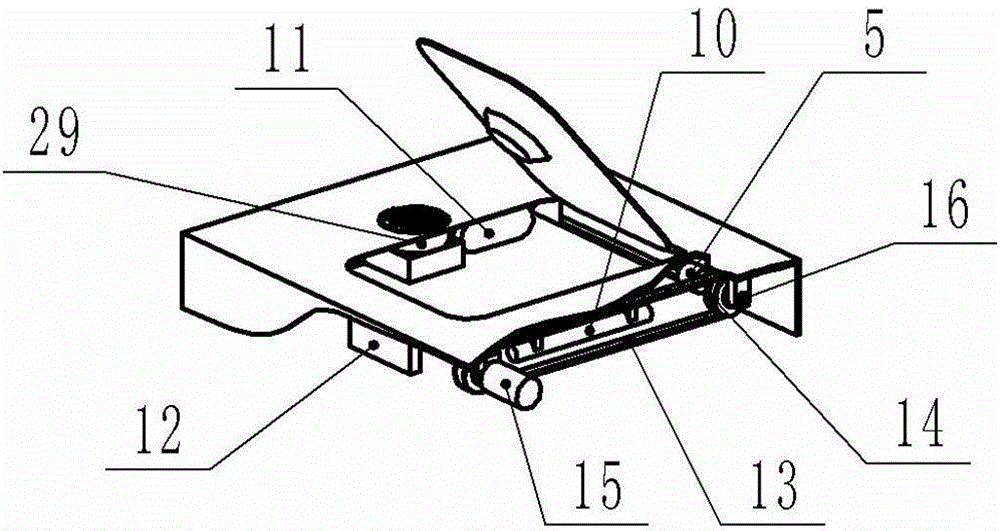

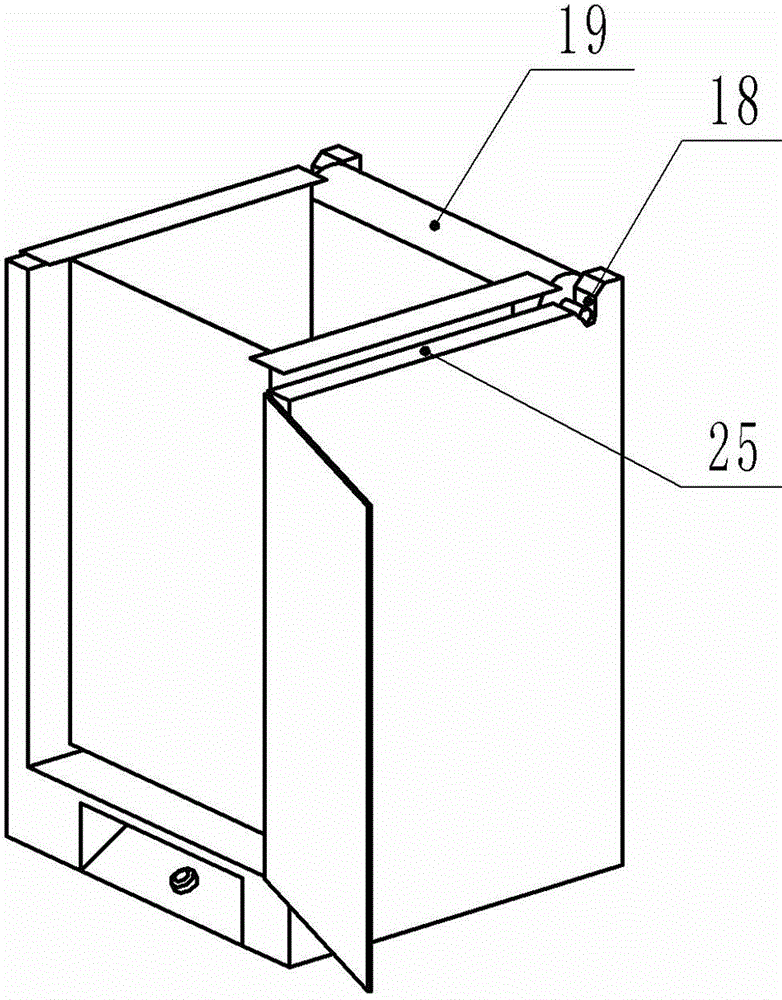

[0028] figure 1 , figure 2 and image 3 The automatic bag-changing disinfection detection trash can, which includes a barrel body 4 provided with a garbage drop-in port on the top, a barrel lid seat 2, and a barrel lid 1 hinged with the barrel lid seat 2, and the barrel lid seat 2 is placed on the barrel body 4, The front of the barrel body 4 is provided with a front door 3 and a lid switch 6 for controlling the opening and closing of the barrel lid. Garbage bag slides 25 are arranged on the left and right sides above the barrel body; Cover motor 5, ultrasonic distance measuring unit 8, display lamp 9, ventilation duct 29, fan, ultraviolet disinfection lamp 10, bag changing switch 17, control module 11 and battery pack 12; Mechanism, the drive mechanism includes four synchronous wheels 14, the synchronous wheels 14 are installed on the lid seat 2 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com