Metering valve and metering method

A metering method and metering valve technology, applied in the field of metering valves, can solve problems such as poor metering results and inaccurate spraying of dosing materials, and achieve the effect of fine and accurate metering results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

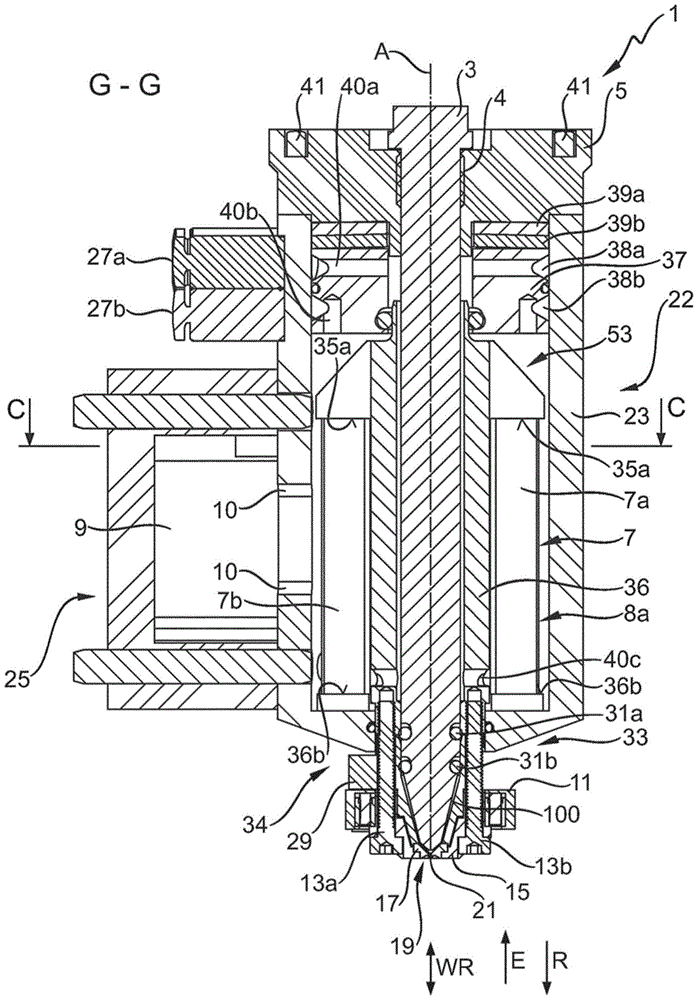

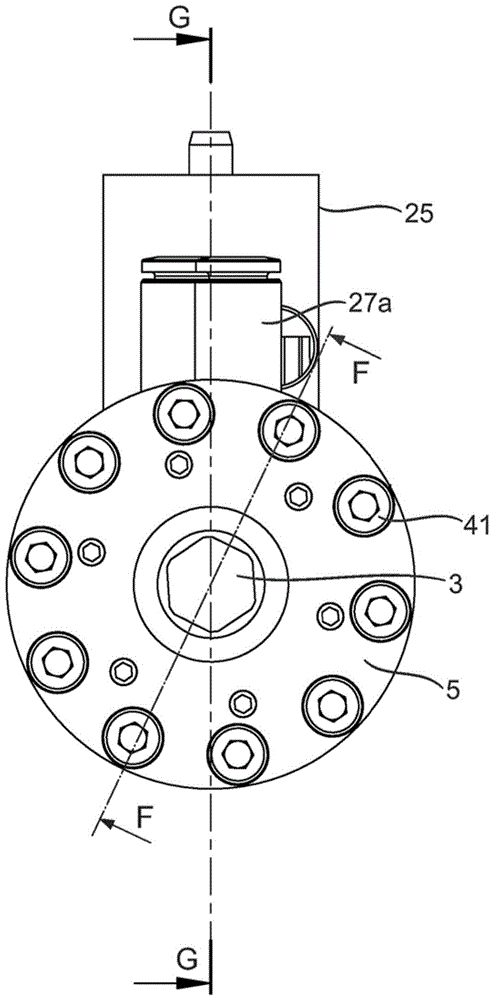

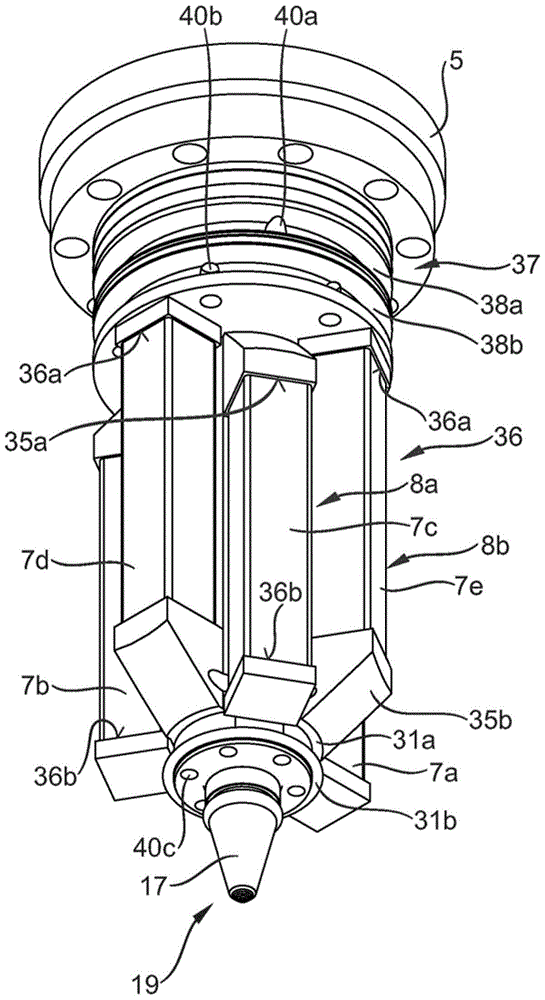

[0105] Figure 1 to Figure 6 A metering valve 1 according to an embodiment of the invention is shown in different full and detailed views, wherein figure 1 and Figure 6 shows along the figure 2 Sectional view of cutting line G-G or F-F in , and basically refer to these two views.

[0106] The metering valve 1 comprises a valve chamber 33 with a nozzle 19 and a valve housing 22 , an actuator chamber 53 is arranged outside the valve chamber 33 . The valve housing 22 comprises a lower first housing part 23 and an upper second housing part 5 in the form of a cover 5 . The two housing parts 5 , 23 are connected to each other by fastening screws 41 .

[0107] The actuator chamber 53 is arranged centrally in the valve housing 22 . Below the cover 5, the first piezoelectric actuator 8a and the second piezoelectric actuator 8b connected by disc springs 39a, 39b and the movably installed support body 37 (ie the support mass) (see Figure 6 ) is oriented in the direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com