Axis automatic positioning deep hole blind hole processing machine tool

A technology for automatic positioning and processing of machine tools, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., and can solve problems such as laboriousness, affecting engineering progress and correct operation, processing quality, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

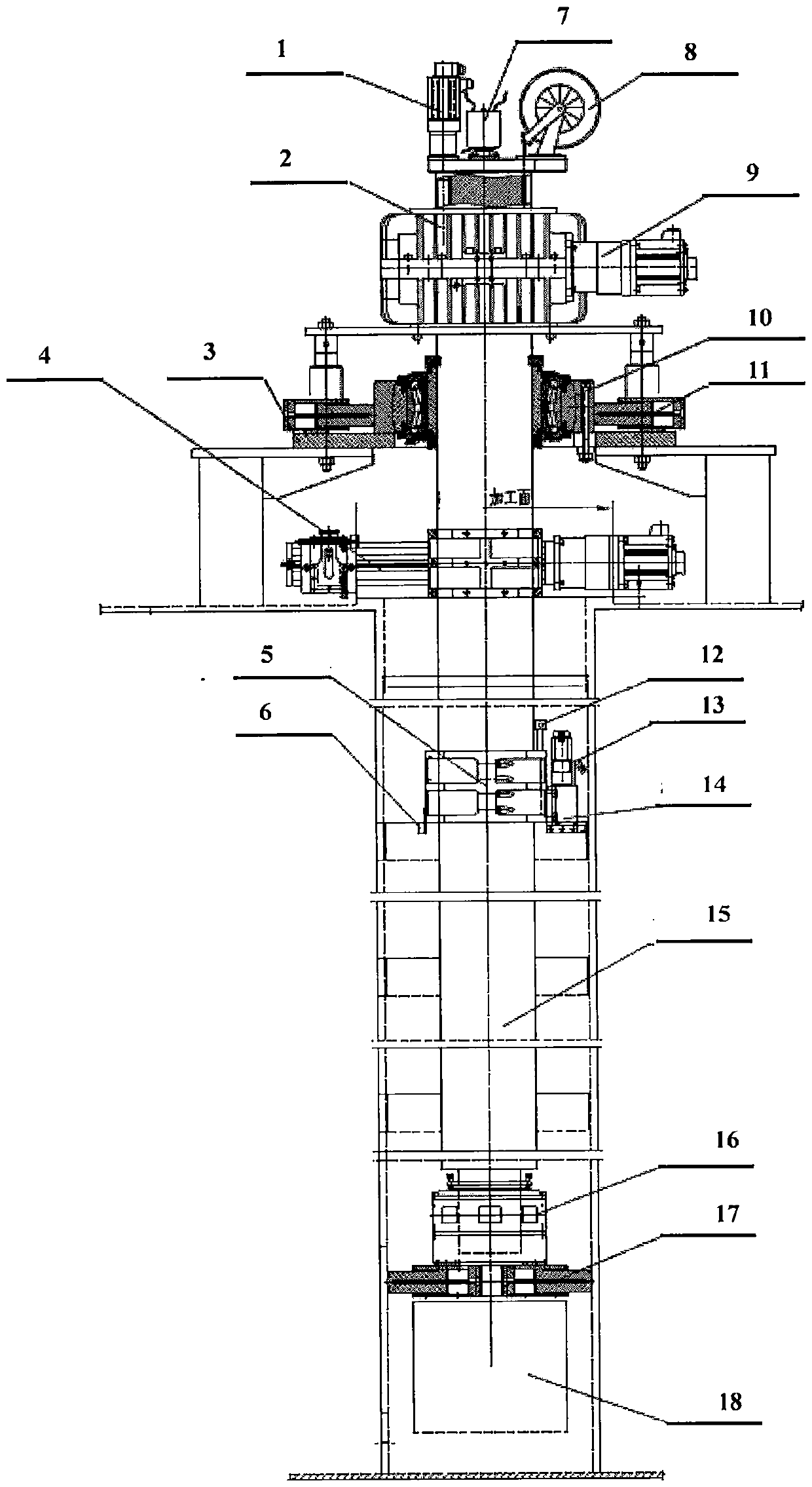

[0013] Such as figure 1 As shown, firstly, the machine tool is initially hoisted and fixed in the hole of the machined part, so that the machining spindle of the machine tool is roughly consistent with the axis of the machined hole and fixed.

[0014] Then establish the datum axis. The method of establishing the reference axis of the machine tool spindle is realized by scanning and detecting the surface of the blind hole of the deep hole through the displacement sensor: scanning and detecting the surface of the blind hole of the deep hole, collecting data, analyzing and calculating the ideal axis position of the blind hole of the deep hole, and calculating the current The deviation of the axis position of the machine tool spindle from the ideal position.

[0015] After the reference axis is determined, the automatic detection of the spindle position of the processing machine tool is carried out. by figure 1 The method shown is taken as an example. The laser displacement sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com