A wire stretching and winding device

A technology of winding device and stretching device, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of uneven center distribution, fewer wires, uneven winding, etc., and achieve Uniform winding and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

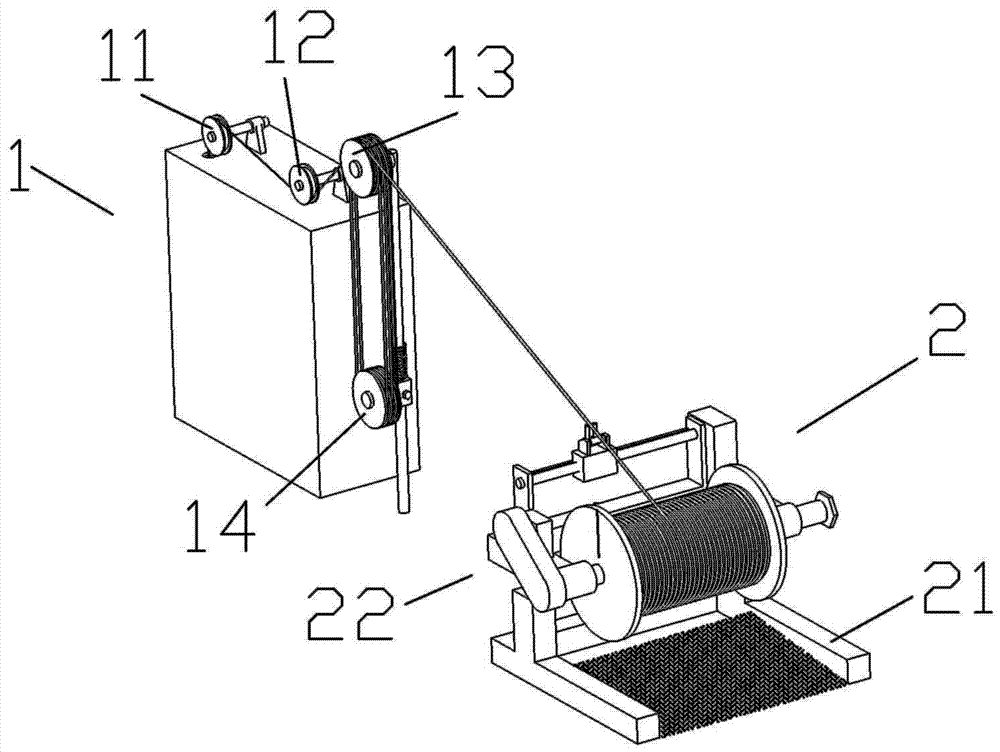

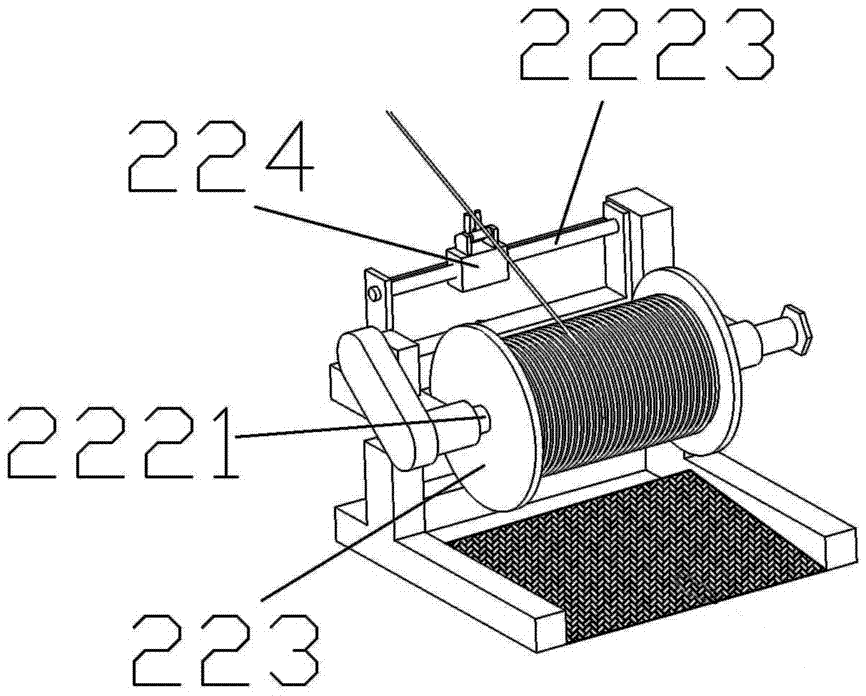

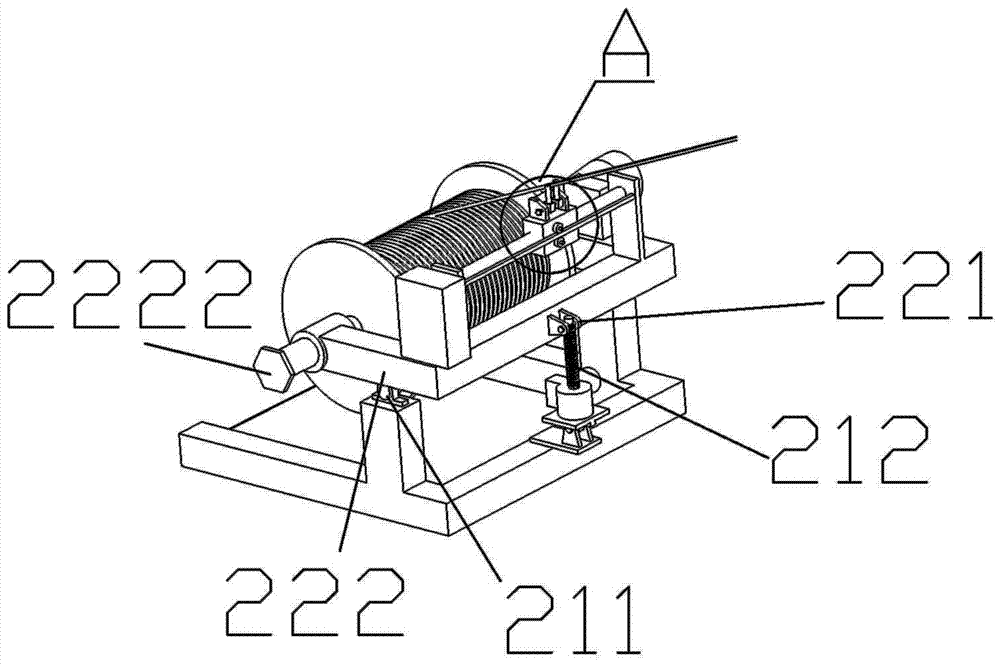

[0033] Embodiment 1: A wire stretching and winding device, including a wire stretching device 1 and a wire winding machine 2 connected behind the wire stretching device 1, the wire winding machine 2 includes a base 21 and a The rolling part 22 on the top, the first shaft structure 211 is connected with the rolling part 22 on both sides of the base 21, and the rolling part 22 can partly rotate around the first shaft structure 211; the rear of the base 21 A connecting rod 212 driven by a motor to move vertically is provided at the end, and the connecting rod 212 is connected with the second shaft structure 221 at the rear end of the winding part 22 .

[0034] The rewinding part 22 includes a rewinding support 222 and a rewinding cylinder 223 located at the front end of the rewinding support 222, and the rewinding cylinder 223 is sleeved on the rewinding shaft 2221 at the front end of the rewinding support 222; the rewinding shaft 2221 One side is a threaded mandrel, and the end ...

Embodiment 2

[0036] Embodiment 2: A wire stretching and winding device, including a wire stretching device 1 and a wire winding machine 2 connected behind the wire stretching device 1, the wire winding machine 2 includes a base 21 and a The rolling part 22 on the top, the first shaft structure 211 is connected with the rolling part 22 on both sides of the base 21, and the rolling part 22 can partly rotate around the first shaft structure 211; the rear of the base 21 A connecting rod 212 driven by a motor to move vertically is provided at the end, and the connecting rod 212 is connected with the second shaft structure 221 at the rear end of the winding part 22 .

[0037] Described electric wire stretching device 1 comprises the first wire pulley 11 and the second wire pulley 12 that are fixed on the platform in turn, the fixed wire pulley 13 that horizontal position is higher than described first wire pulley 11 and the second wire pulley 12 and is positioned at The movable pulley 14 below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com