Patents

Literature

37results about How to "Improve the take-up effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

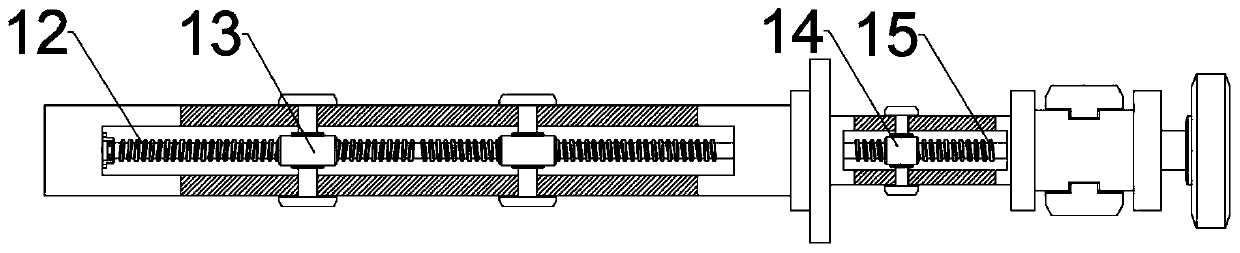

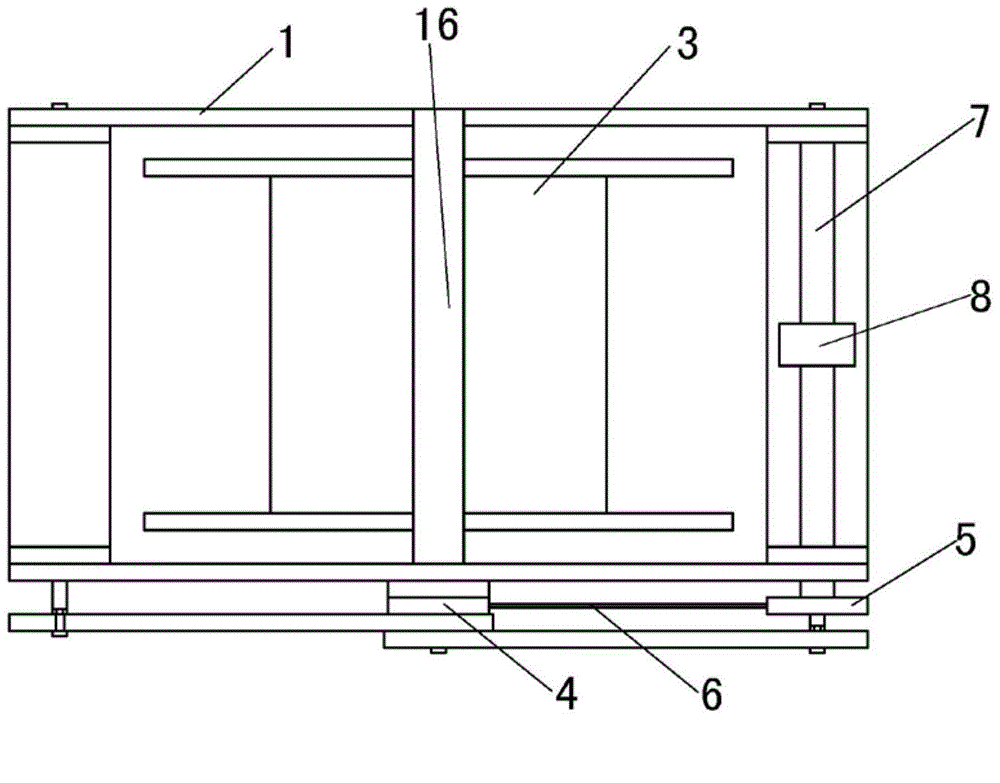

Reel-up system and reel-up method thereof

InactiveCN102837992AImprove the take-up effectImprove productivityFilament handlingProduction rateProgrammable logic controller

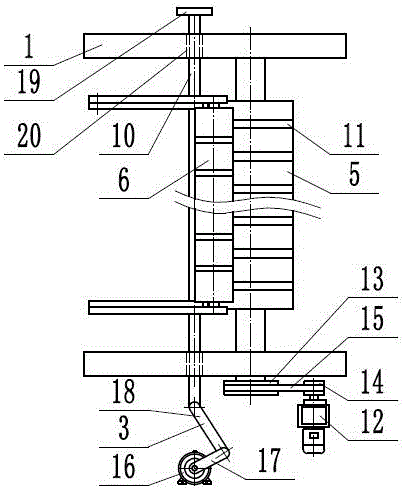

The invention discloses a reel-up system and a reel-up method thereof. The reel-up system comprises a plurality of reel-up units, and each reel-up unit comprises a reel, a direct current motor, a wire spool, a servo motor and a PLC (Programmable Logic Controller) controller, wherein each reel comprises a left upright plate and a right upright plate, and the direct current motor is arranged between the left upright plate and the right upright plate and connected with a winding shaft which is connected with the wire spool; the inner side of each wire spool is provided with a connecting plate, the center of the connecting plate is provided with a round hole, and both ends of the connecting plate are respectively provided with a wire swing rod; the round hole is sleeved on the winding shaft; the wire swing rod passes through the right upright plate, and the tail end of the wire swing rod is respectively connected with a screw rod; the outer side of each screw rod is connected with a belt pulley, and the belt pulley is connected with the servo motor; an L-shaped rack is arranged below the reel, and the top of the L-shape rack is provided with an infrared photoelectric sensor; and one side of each reel is provided with two guide wheels, and the guide wheel close to the reel is connected with a gravity sensor. The reel-up system provided by the invention has the advantages of good reel-up effect and high productivity.

Owner:SUZHOU YOURBEST NEW TYPE MATERIALS

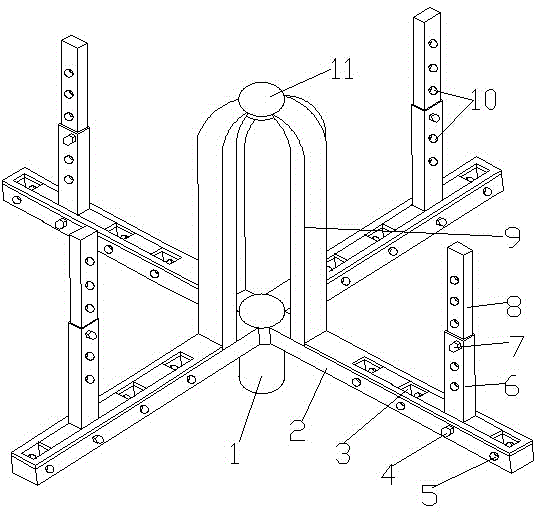

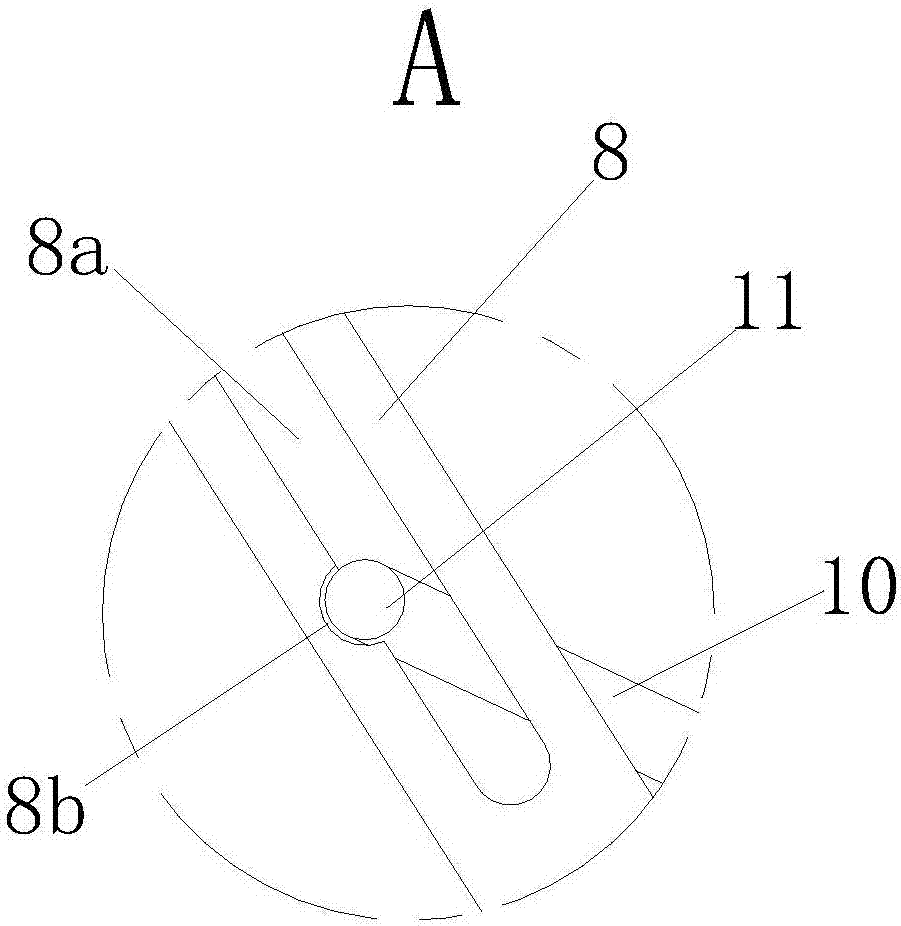

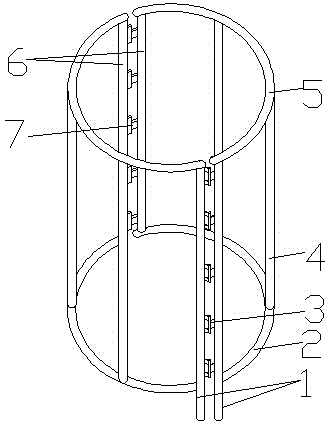

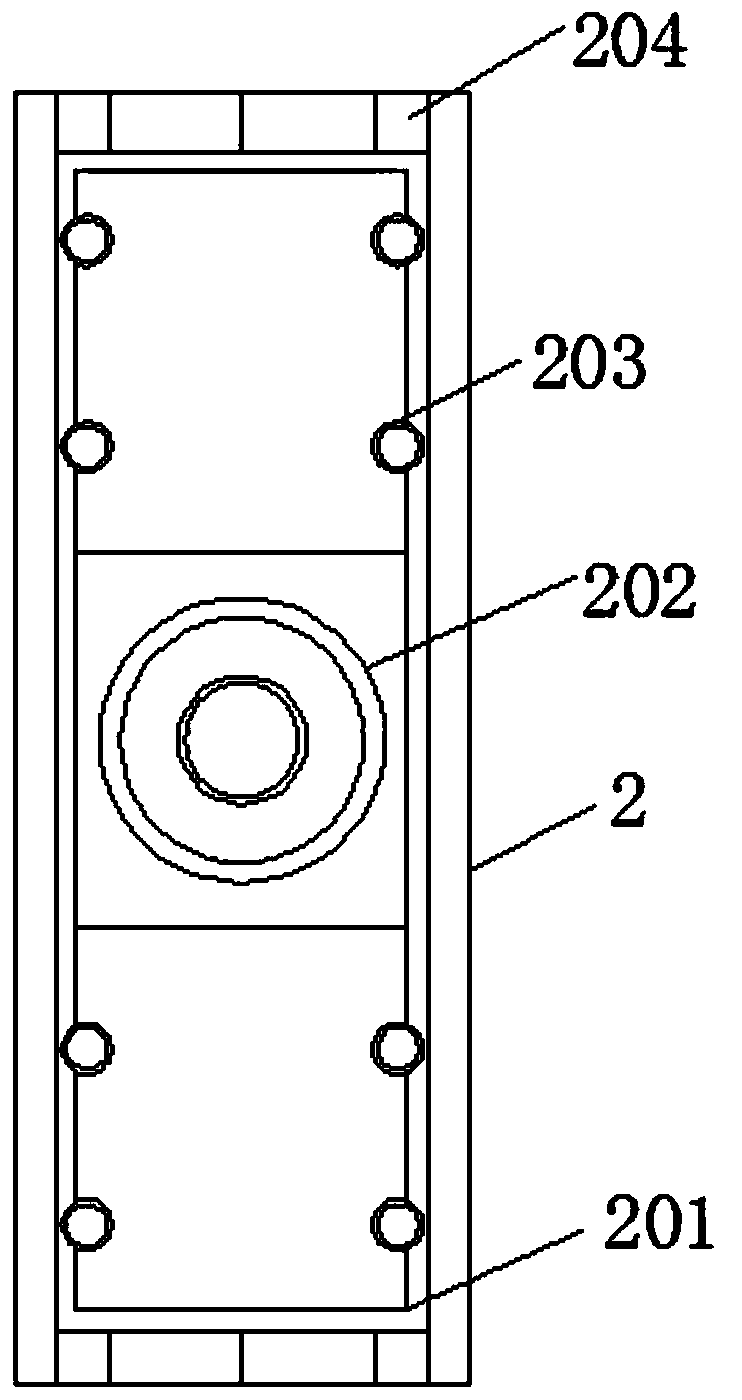

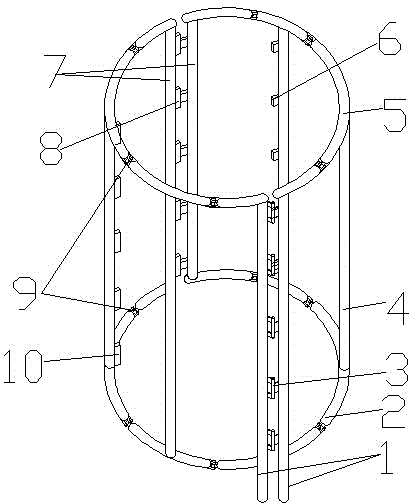

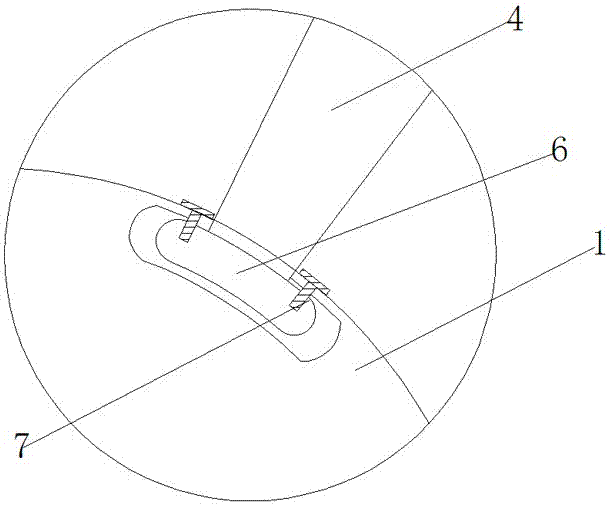

Vertical type adjustable take-up reel

ActiveCN104464953AGood take-up effectAvoid being stretchedFilament handlingCable/conductor manufactureMachiningScrew thread

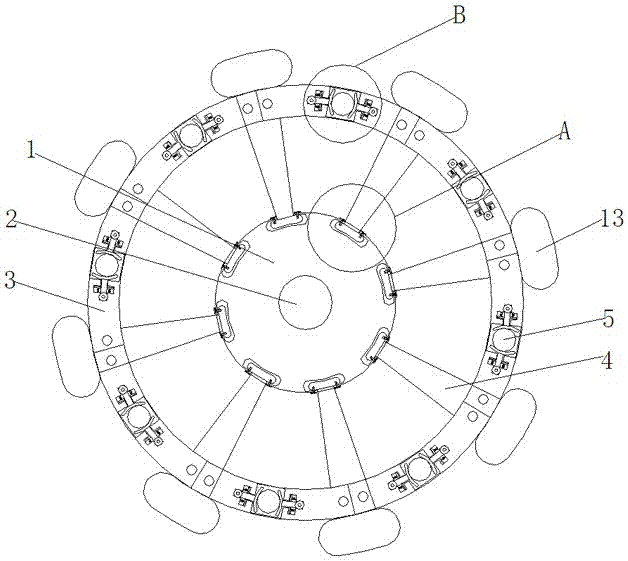

The invention discloses a vertical type adjustable take-up reel and belongs to the field of machining equipment. The vertical type adjustable take-up reel comprises a rotating shaft and three to six take-up base plates, each take-up base plate comprises limiting rollers and a take-up roller, the take-up base plates are fixed to the top end of the rotating shaft, each limiting roller comprises a roller sleeve and a roller rod, each roller rod is sleeved with the corresponding roller sleeve, second threaded holes are formed in the same side faces of each roller rod and the corresponding roller sleeve, and each roller rod and the corresponding roller sleeve are fixed through a second screw; the upper end face of each take-up base plate is fixedly provided with the corresponding take-up roller and grooves, the roller sleeves are arranged in the grooves, first threaded holes are formed in the side faces of each take-up base plate and penetrate through the corresponding grooves, threaded holes are also formed in the positions, corresponding to the first threaded holes, of the roller sleeves when the roller sleeves are disposed in the grooves, and the roller sleeves are fixed in the grooves through first screws. The limiting rollers are arranged on the upper end faces of the take-up base plates, so that adjustability of the distance between the take-up rollers and the limiting rollers and the overall height of the limiting rollers is achieved; thus, taking up of cable coils of different sizes and heights can be achieved, and the limiting rollers can also prevent the phenomenon that cables get rid of restraint in the transverse direction and are in a mess when plenty of winding is conducted.

Owner:WUHU CHANGRUN SPECIAL COPPER

Novel vertical take-up reel

The invention discloses a novel vertical take-up reel, and belongs to the field of machining equipment. The novel vertical take-up reel comprises a rotating shaft and three to six take-up base plates. Each take-up base plate comprises a limiting roll and a take-up roll and is fixed to the top end of the rotating shaft, wherein the take-up roll is fixed to the upper end face of the side, close to the rotating shaft, of the take-up base plate, a plurality of grooves are formed in the upper end face of the take-up base plate, the limiting roll is arranged in one groove, horizontal threaded holes throughout the grooves are formed in the side faces of the take-up base plate, and when placed in the corresponding groove, the limiting roll is provided with a threaded hole in the part corresponding to the threaded holes and is fixed through a nut after a screw penetrates through the threaded holes. Because the limiting rolls capable of being fixed in the different grooves are arranged on the upper end faces of the take-up base plates, the distance between the take-up rolls and the limiting rolls can be adjusted, and cables of different sizes can be taken up; besides, the limiting rolls can avoid the phenomenon that when lots of cables are taken up, the cables are unconstrained and get messy in the transverse direction.

Owner:WUHU CHANGRUN SPECIAL COPPER

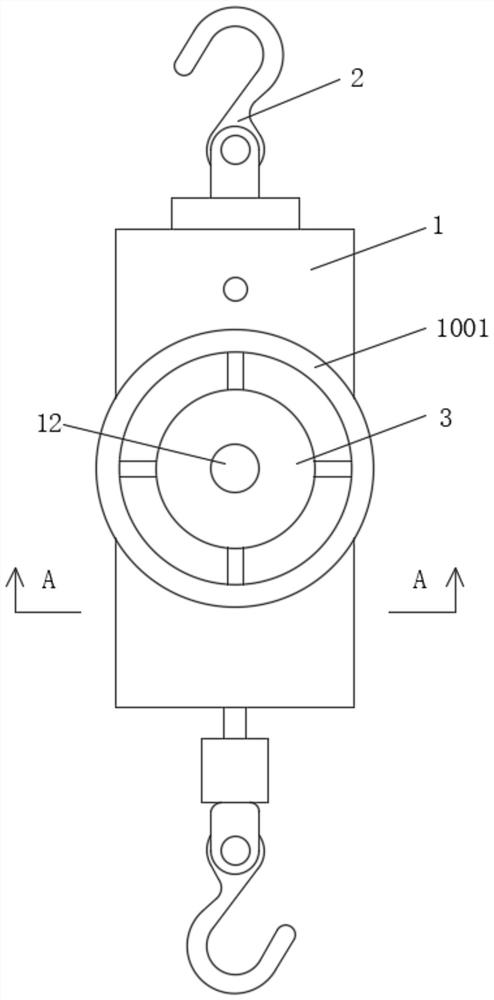

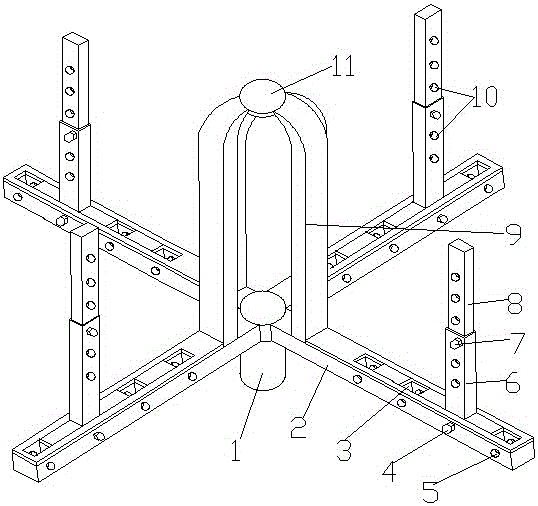

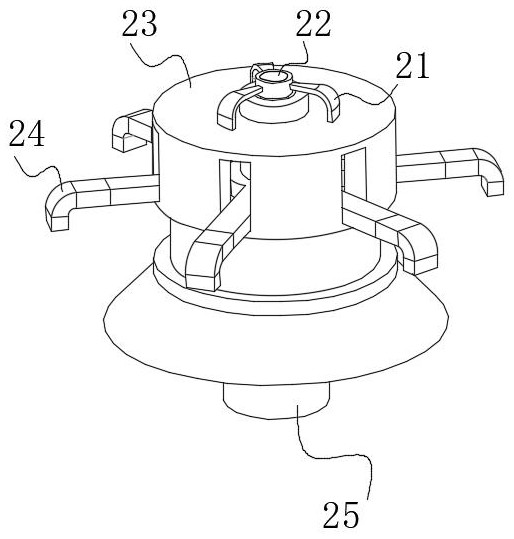

Swivel type ratchet tightener

ActiveCN113270816AGuaranteed normal rotationAccuracy adjustableAdjusting/maintaining mechanical tensionApparatus for overhead lines/cablesRatchetGear wheel

The invention relates to the technical field of power systems, and discloses a swivel type ratchet tightener. A rotating box is fixedly mounted at one side of a supporting frame, a transmission box is fixedly mounted at the other side of the supporting frame, and a take-up wheel is fixedly mounted on an outer ring of the rotating shaft in the supporting frame; a wire guide block is fixedly mounted at the position, located at the bottom of the take-up wheel, in the supporting frame, the outer ring of a gear cavity is movably sleeved with a rotating disc, and a driving rotating sleeve fixedly connected with the rotating shaft is movably installed in the center of the gear cavity; a pressure adjusting screw rod is sleeved with a sleeve hole in a threaded manner, a hydraulic cavity is formed at the bottom in the transmission box, close to the inner side, and a rotating disc fixedly connected with a second transmission wheel is movably installed in the hydraulic cavity. The middle of the wire guide block is movably sleeved with a wire guide sliding block, and by means of the improvement of the rotating disc and the structural design and transmission design of the wire guide block, it is guaranteed that when the wire tightener is used, the usage precision can be guaranteed, and a wire tightening effect is better.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

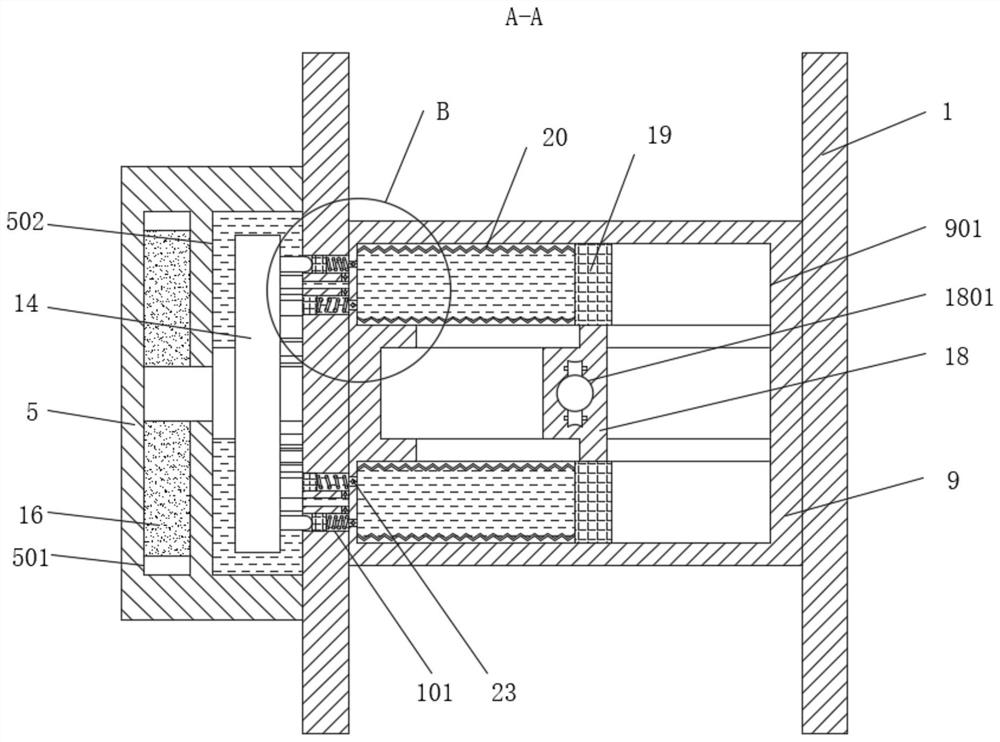

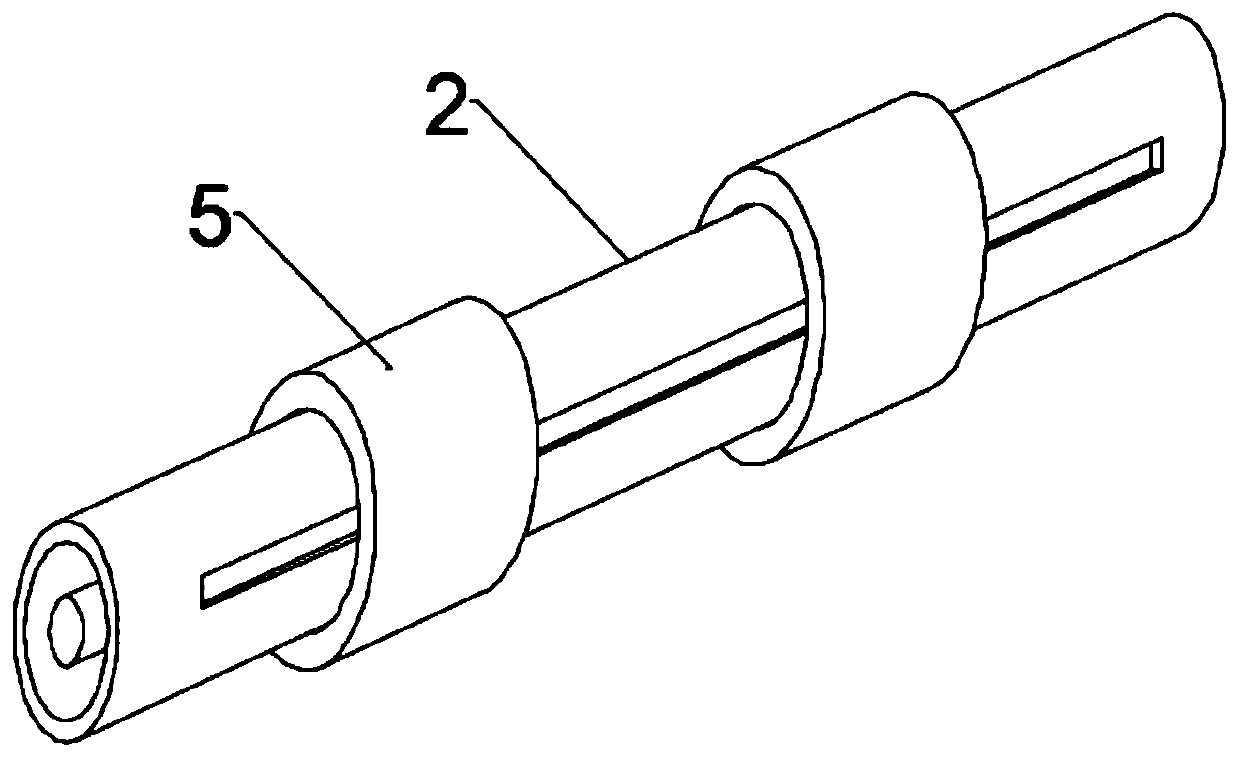

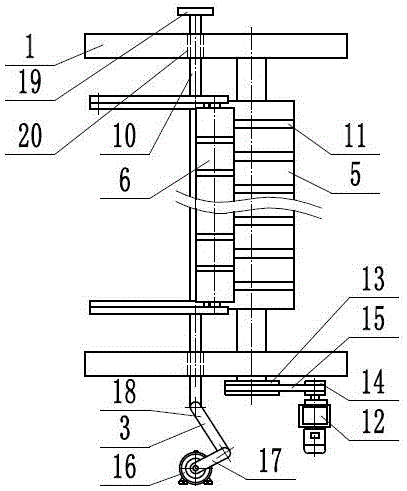

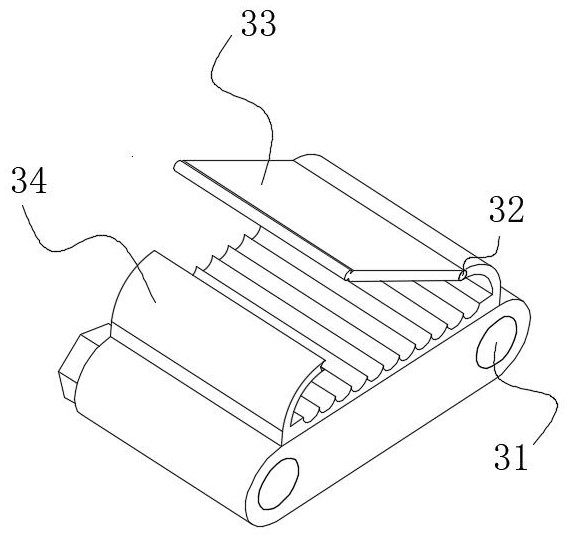

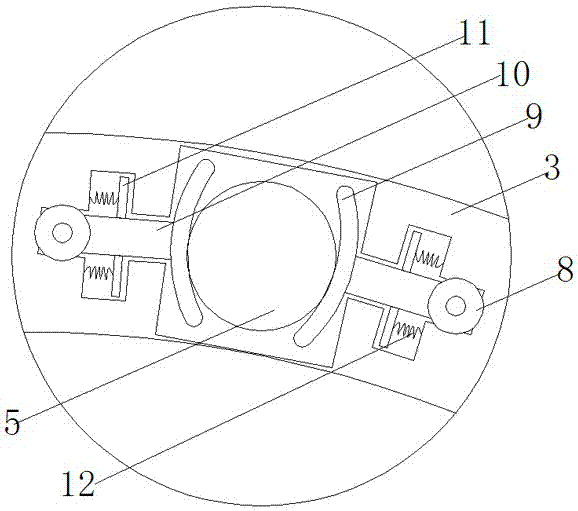

Take-up roller structure, take-up mechanism and textile equipment

InactiveCN111483879ARealize radial limitRealize axial limitFilament handlingStructural engineeringMechanical engineering

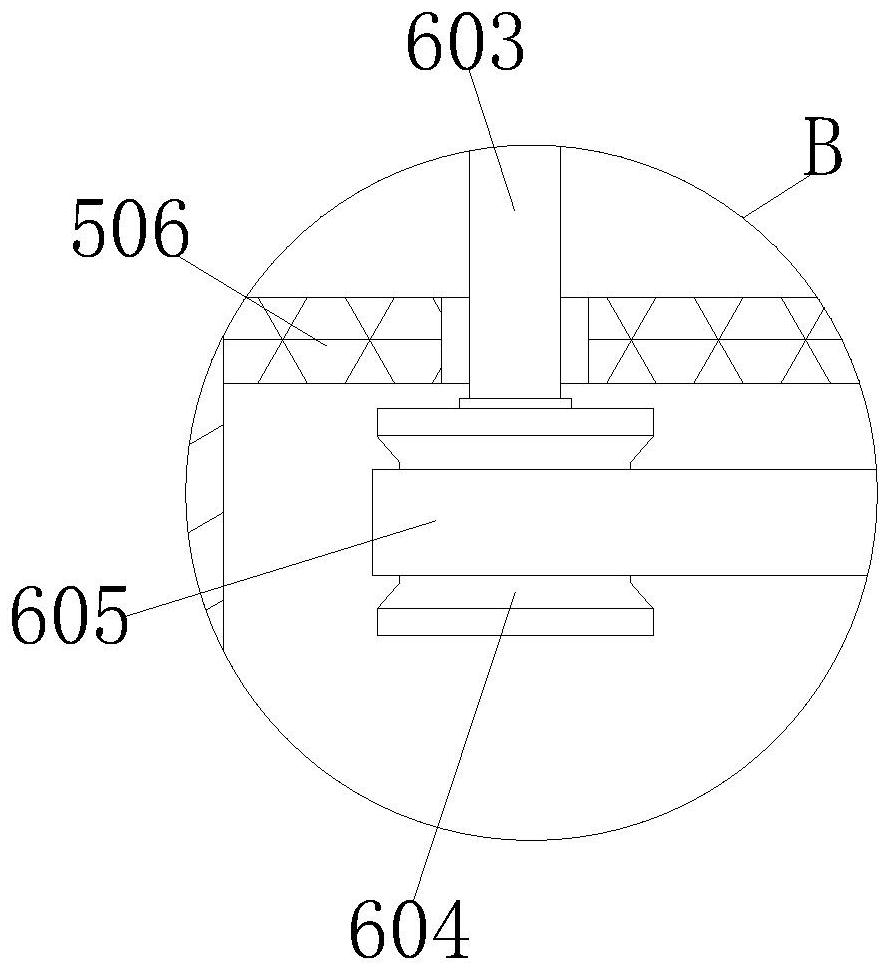

The invention relates to the technical field of textile, in particular to a take-up roller structure, a take-up mechanism and textile equipment. The take-up roller structure comprises a rotary shaft,a baffle plate, a wire roller, a resisting assembly, a pressing assembly and a regulating mechanism, wherein the baffle plate is fixed to one end of the rotary shaft; the wire roller sleeves the rotary shaft; the resisting assembly is mounted on the rotary shaft, and abuts against the inner wall of the wire roller; the pressing assembly is mounted at one end, away from the baffle plate, of the rotary shaft; the pressing assembly is matched with the baffle plate for axially limiting the wire roller; the regulating mechanism is mounted at one end of the rotary shaft and is connected to the resisting assembly and the pressing assembly; the wire roller sleeves the rotary shaft, and one end of the wire roller abuts against the baffle plate; the regulating mechanism drives the resisting assemblyand the pressing assembly to synchronously move, so that radial limiting and axial limiting of the wire roller are realized, and therefore, connecting stability between the wire roller and the rotaryshaft is ensured, and the wire roller can be effectively prevented from rotating relative to the rotary shaft.

Owner:徐州华通手套有限公司

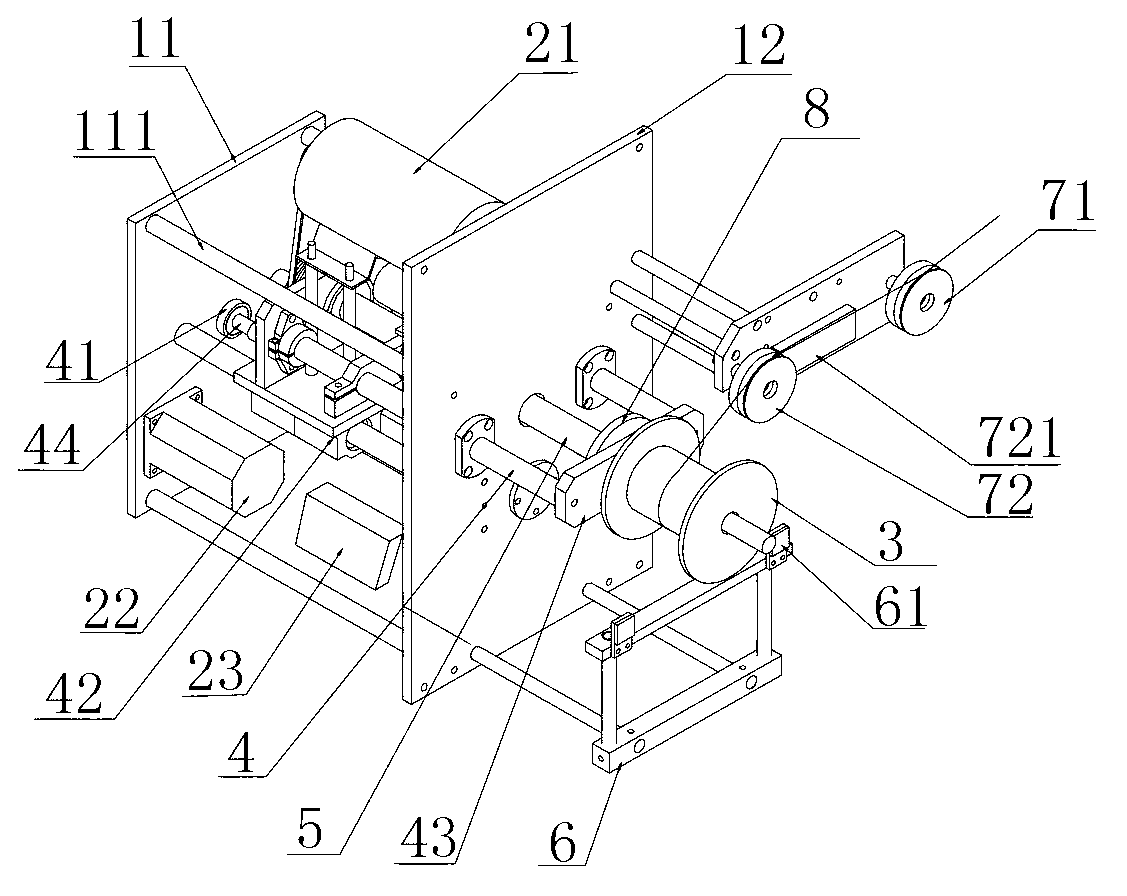

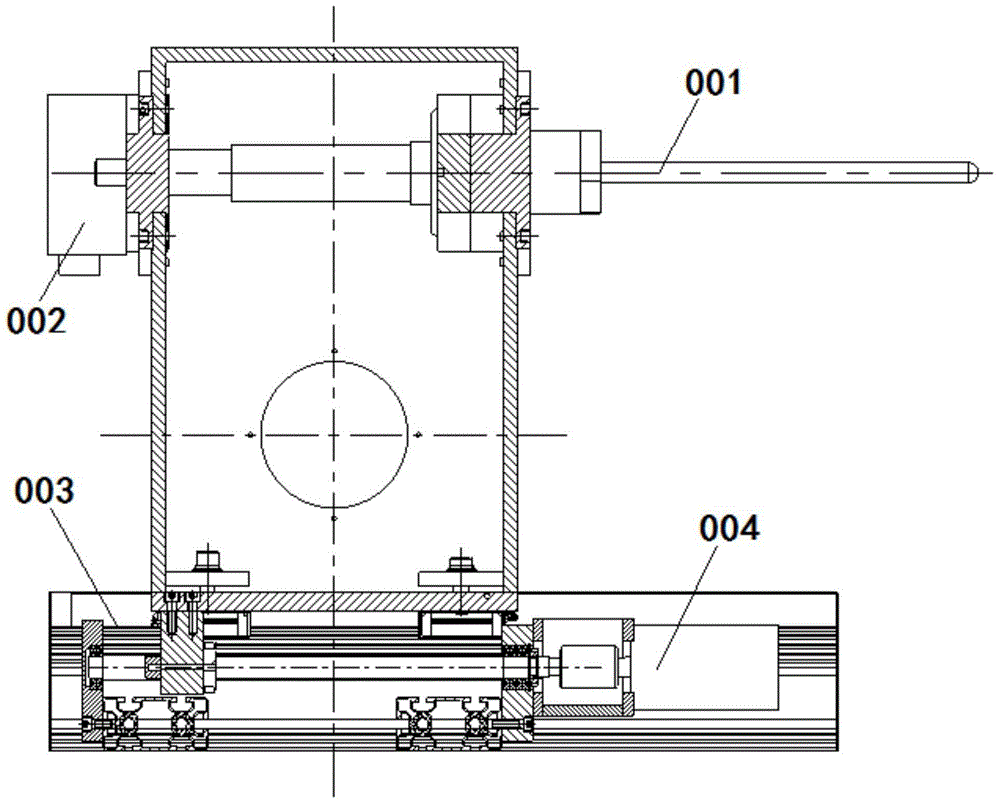

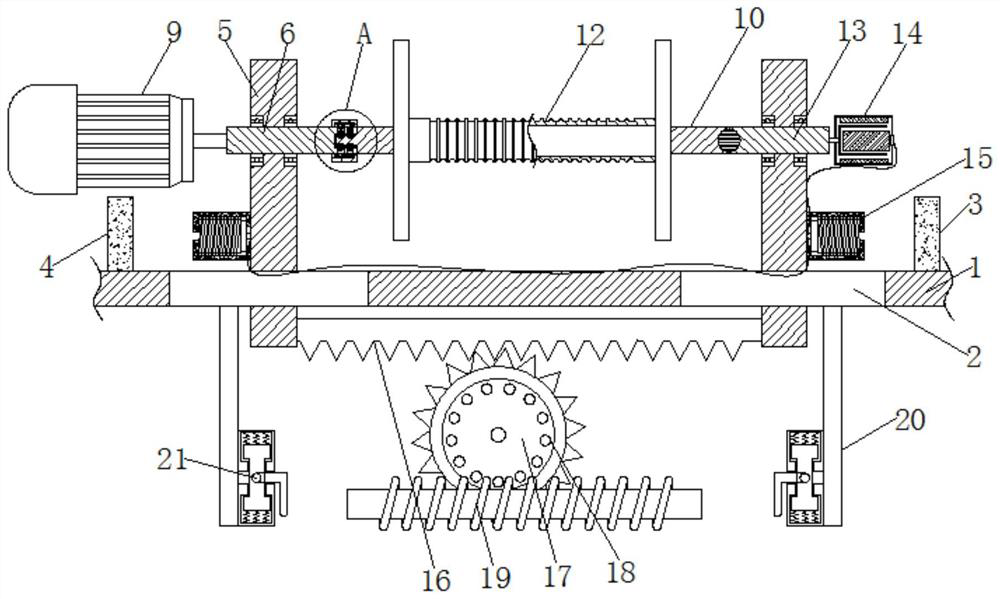

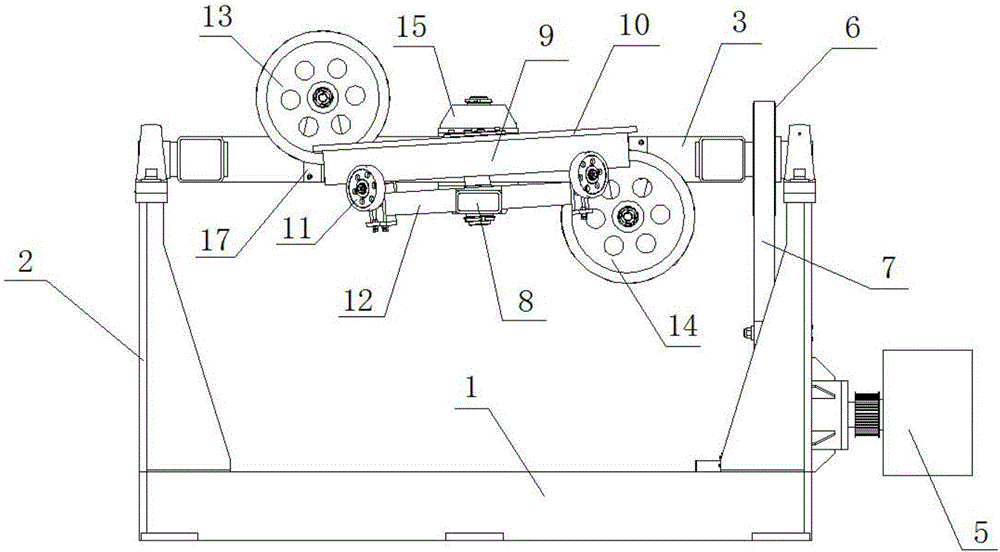

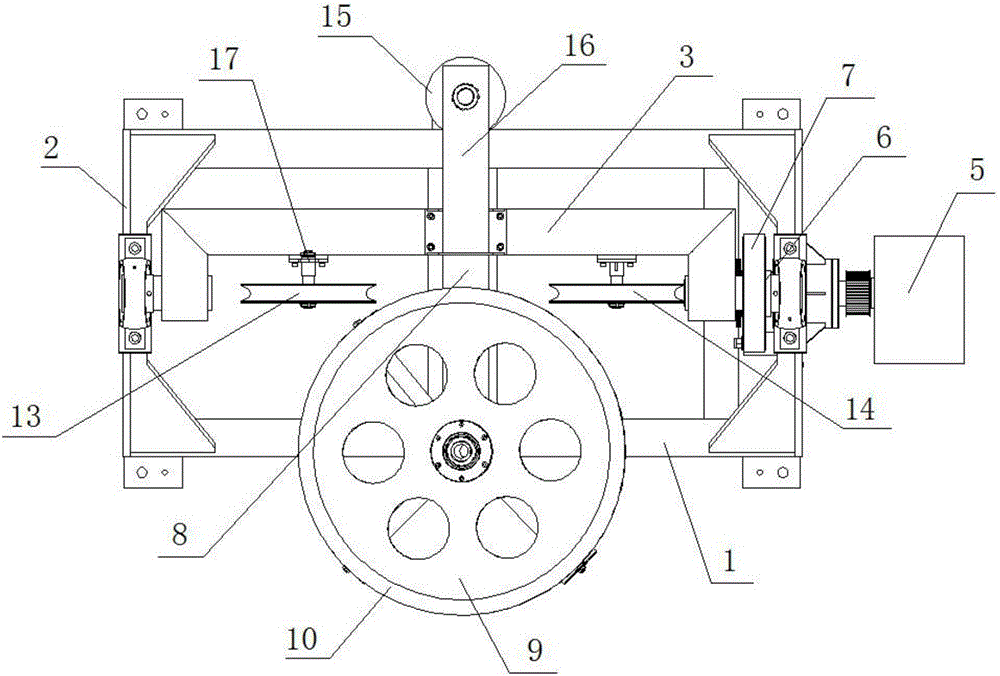

Full-automatic winding device and winding displacement control method thereof

ActiveCN104670987AEliminate voids in areas prone to wedgesSolve the technical problem that is prone to jamming when paying offFilament handlingAutomatic controlDisplacement control

The invention provides a full-automatic winding device and a winding displacement control method thereof and solves technical problems that stagnation in the millisecond level is easy to be produced instantly due to reversing and number of turns of wires wound on each layer of workpiece tray shaft is uncontrollable during winding displacement control in the prior art are solved. The method includes the steps of S1, calculating time t spent for a transverse shaft of the full-automatic winding device in transversely moving the distance L; S2, dividing the t into a t1 and t2, wherein t=t1+t2; delaying the time duration of the t1 for transmitting pulse signals to a first servo motor each time the first servo motor receives the reversing pulse signals, and sending the pulse signals of accelerated movement with duration of t2 and frequency of (t*f) / t2 to the first servo motor at the end of the time t1; sending the pulse signals to the first servo motor with frequency of f within the time from the end of the time t2 to the next time that the reversing pulse signals are received by the first servo motor. The full-automatic winding device is controlled automatically by the application of the above method.

Owner:XIAN TELISON NEW MATERIAL

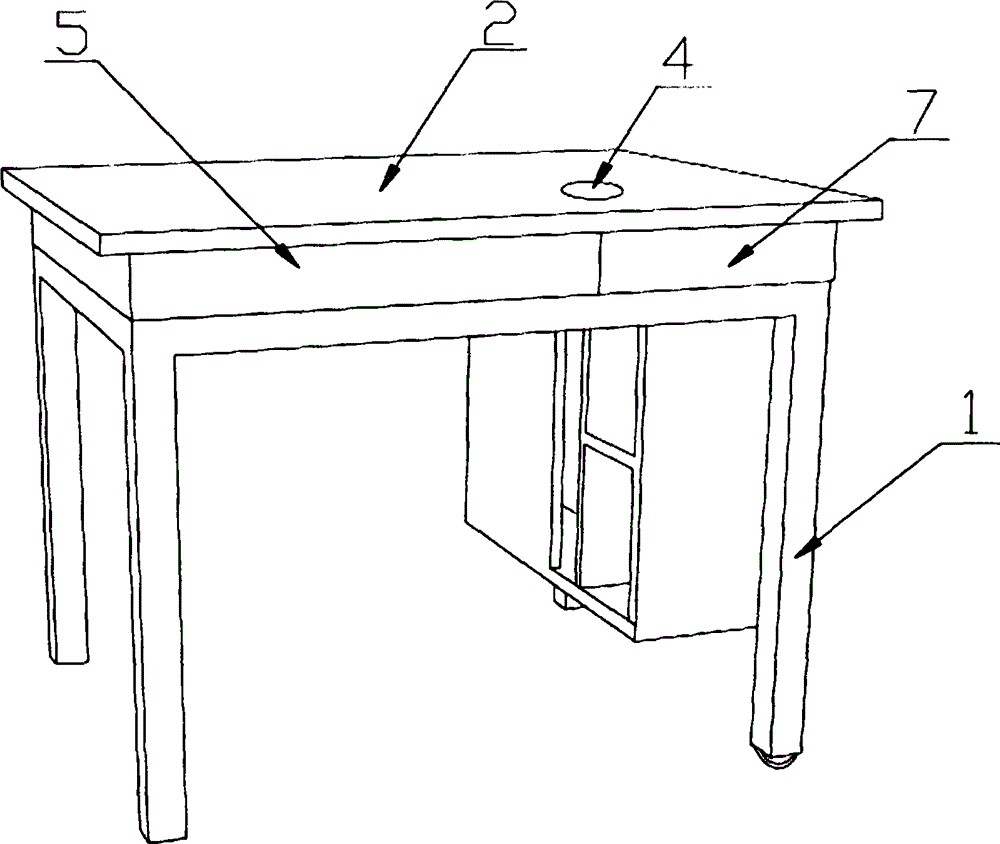

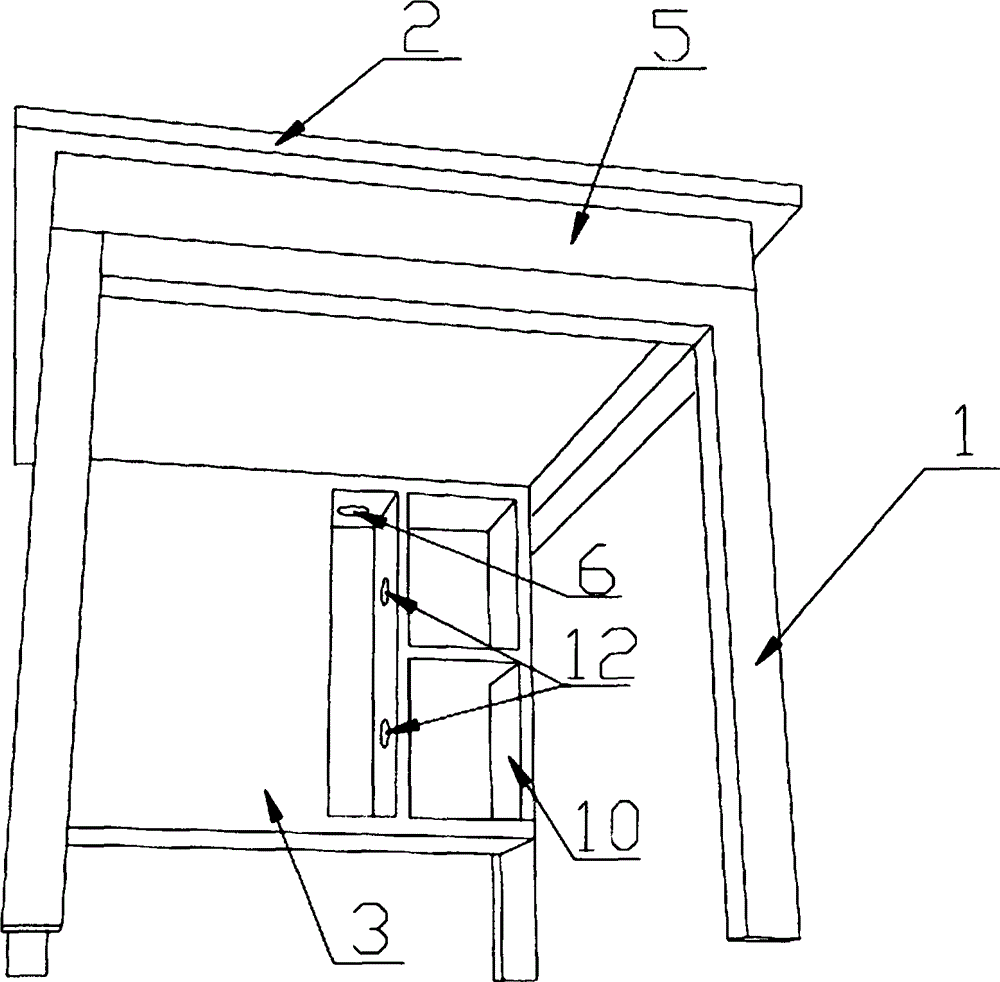

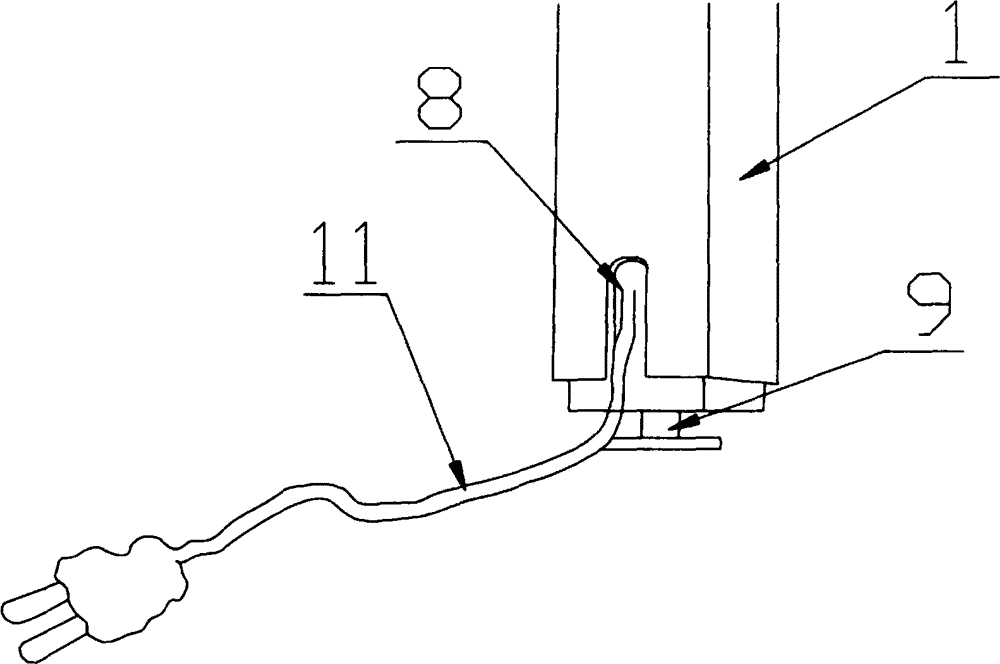

Computer desk capable of hiding wire

The invention discloses a computer desk capable of hiding a wire. The computer desk capable of hiding the wire comprises desk legs (1), a desk top (2), a mainframe box (3) and a wire plugging hole (4). The computer desk capable of hiding the wire is characterized in that a wire collecting box (5) stretches downward and a wire collecting box (5) is arranged. One of the desk legs (1) is provided with a through hole at the inside and is communicated with the space of the wire collecting box (5). The base plate of the wire collecting box (5) and the mainframe box (3) are provided with a communicated wire-enter hole (6). A door (7)is arranged at the rear portion of the wire collecting box (5). A concave groove is formed in the lower portion of the desk leg (1) with the through hole in the inside. The bottoms of the desk legs (1) are provided with desk leg pads (9) matched with the desk legs (1). According to the computer desk capable of hiding the wire, a patch board can be inserted in the wire collecting box, a plug of the patch board is connected with a socket through the through hole in one desk leg, the structure is simple, the outlook is attractive, and the wire collecting effect is good.

Owner:魏化平

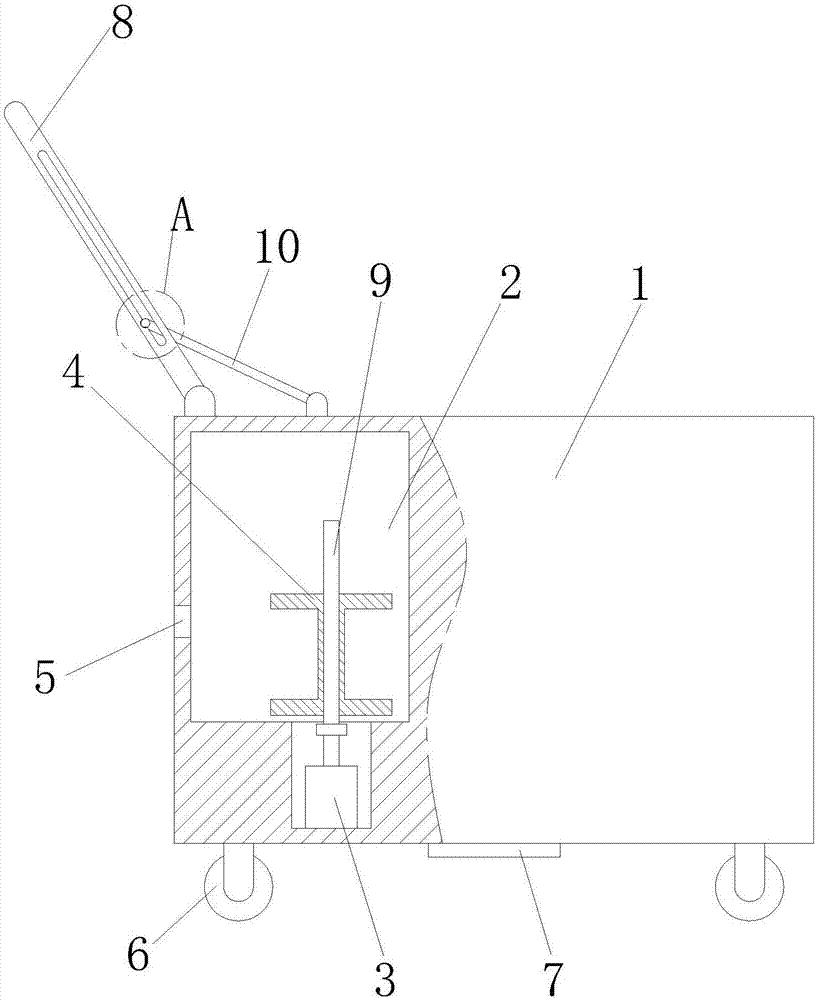

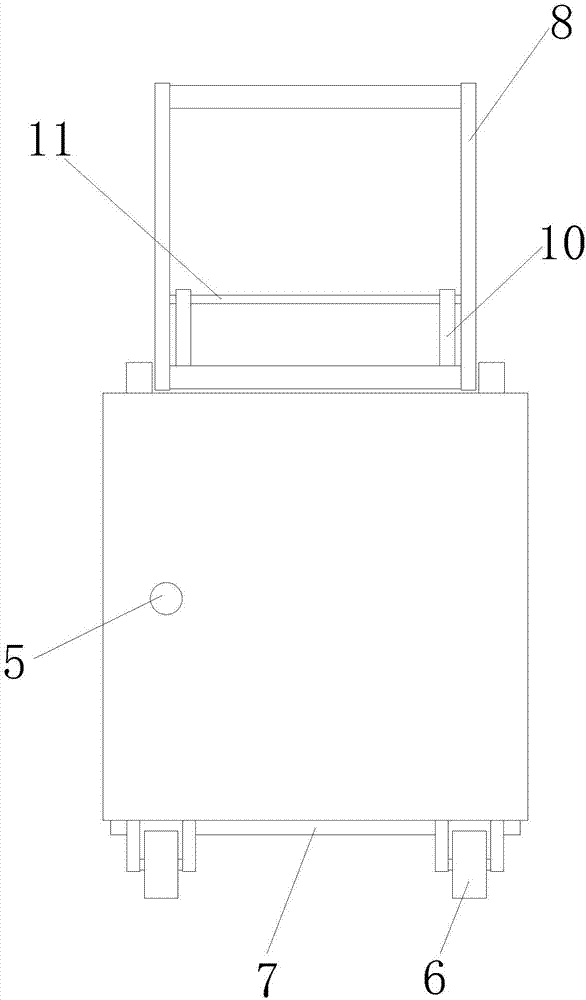

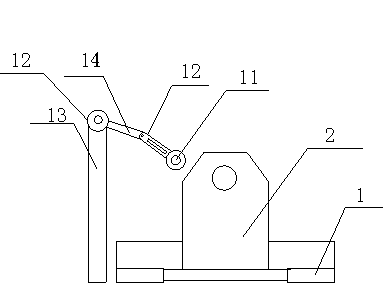

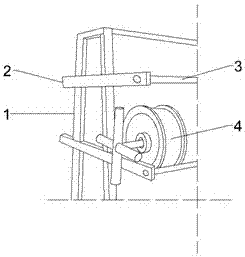

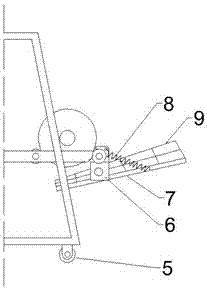

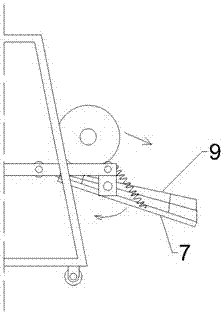

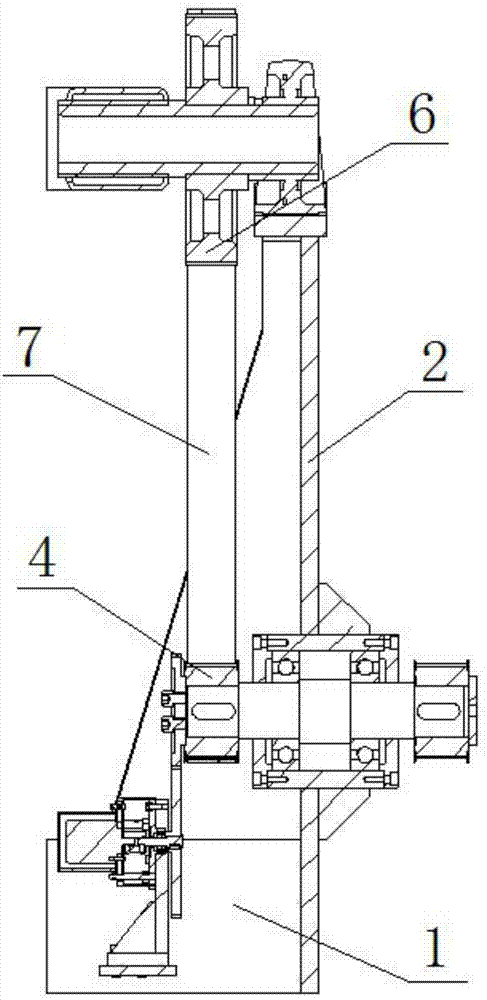

Portable welding machine

InactiveCN107081510AReasonable structural designEasy to useWelding accessoriesMotor driveEngineering

The invention relates to a portable welding machine. The portable welding machine comprises a welding machine shell. A welding machine body is installed in the welding machine shell. A cavity is arranged in the welding machine shell. A motor is installed at the bottom of the cavity. The motor is connected with a lead screw provided with a take-up wheel. The left end face of the welding machine shell is provided with a weld wire hole. Wheels are installed at the bottom of the welding machine shell. A wear-proof plate is fixedly installed at the bottom of the welding machine shell. A push rod is installed on the upper portion of the welding machine shell. The motor drives the take-up well to achieve automatic taking up. The foldable type push rod can be stored in the welding machine shell when not used. The wear-proof plate is arranged at the bottom of the welding machine shell, so that the welding machine shell cannot be damaged when passing by barriers. The portable welding machine is reasonable in structural design and convenient to use; the automatic take-up process is achieved, and the take-up effect is good; and compared with the product of the same type, the portable welding machine is smaller in size, convenient to transport and wide in application range.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

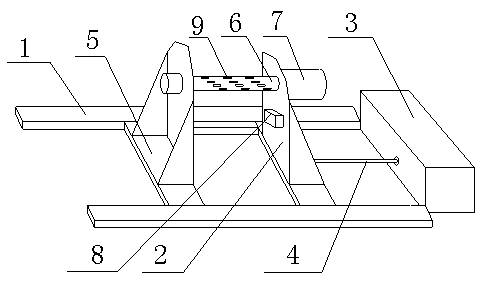

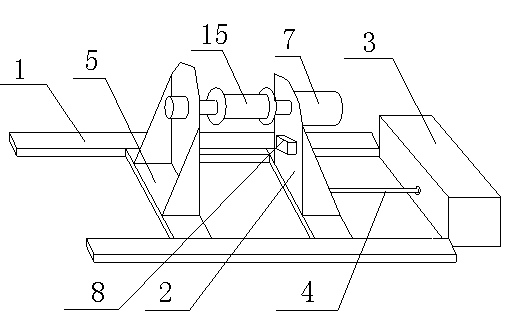

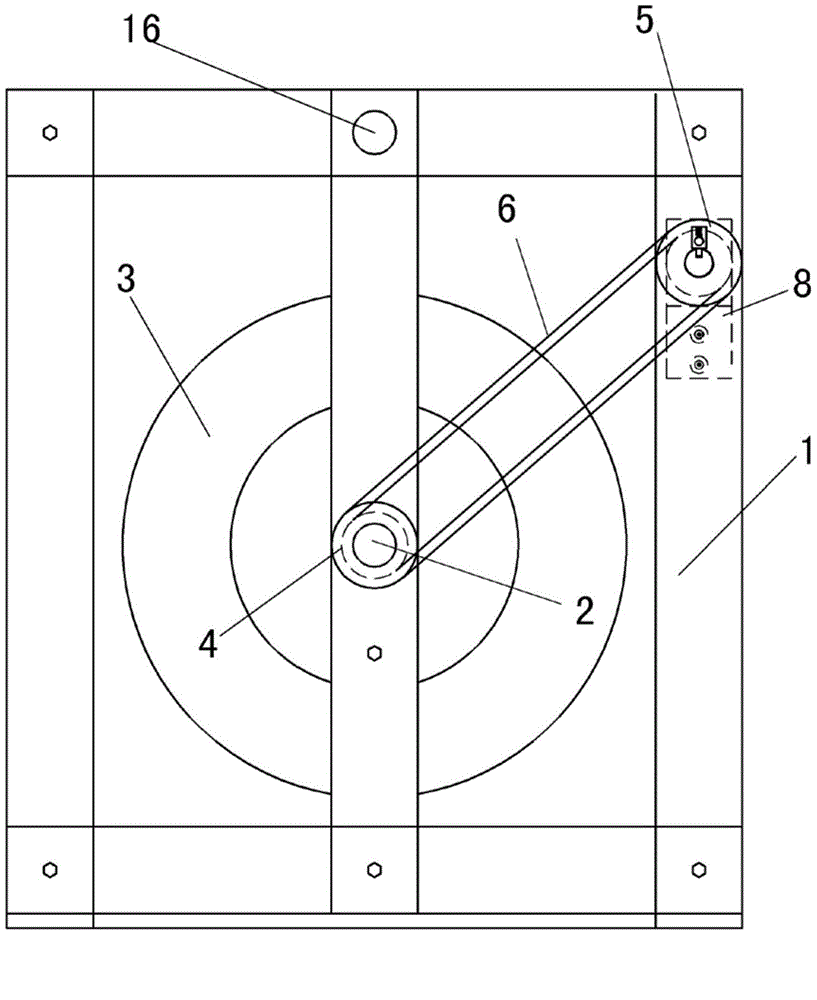

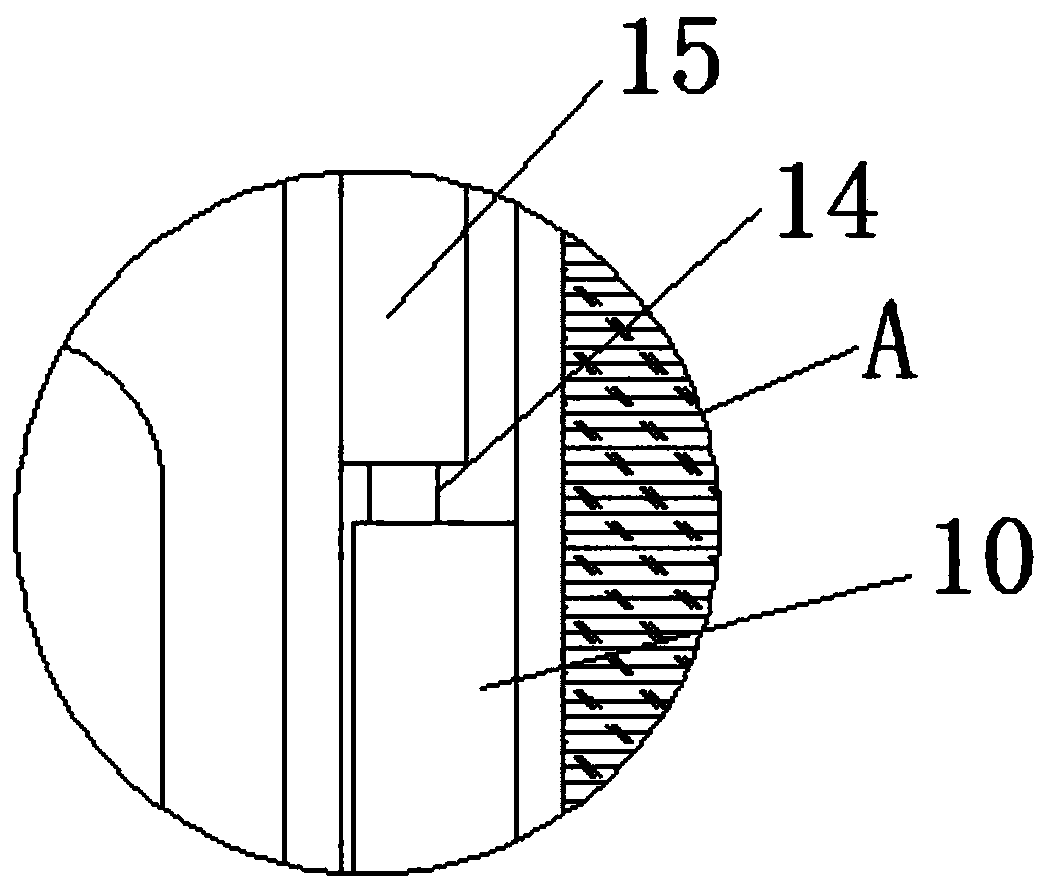

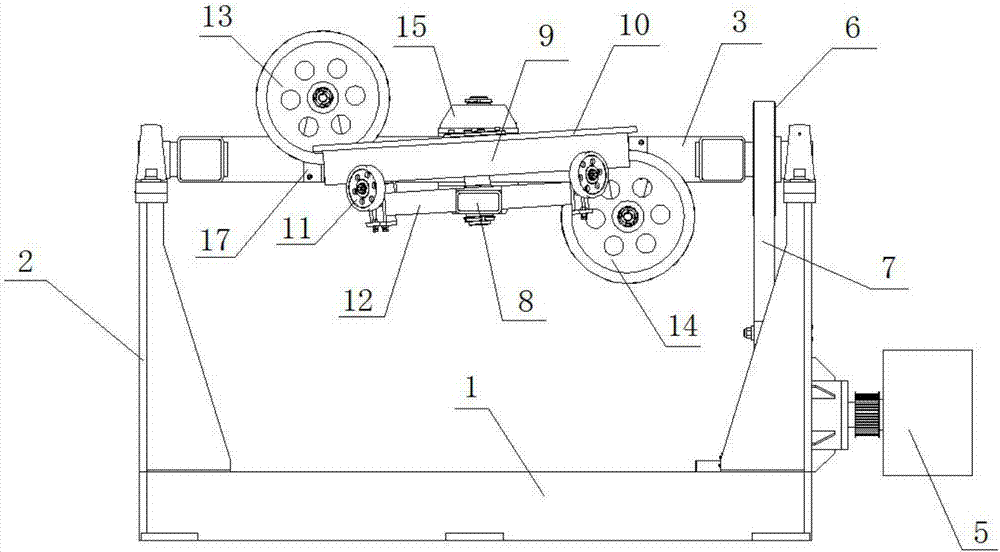

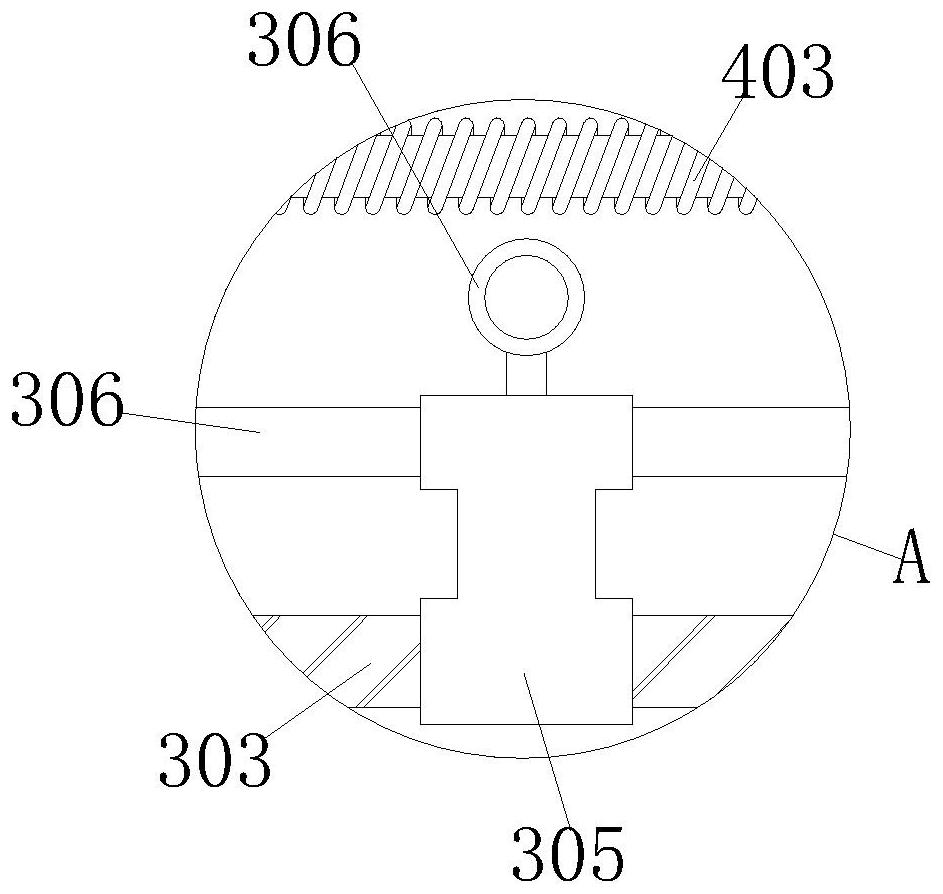

Optical fiber winding machine provided with wire pressing wheel

InactiveCN103508258AIncrease the amount of take-upImprove the take-up effectFilament handlingWinding machineEngineering

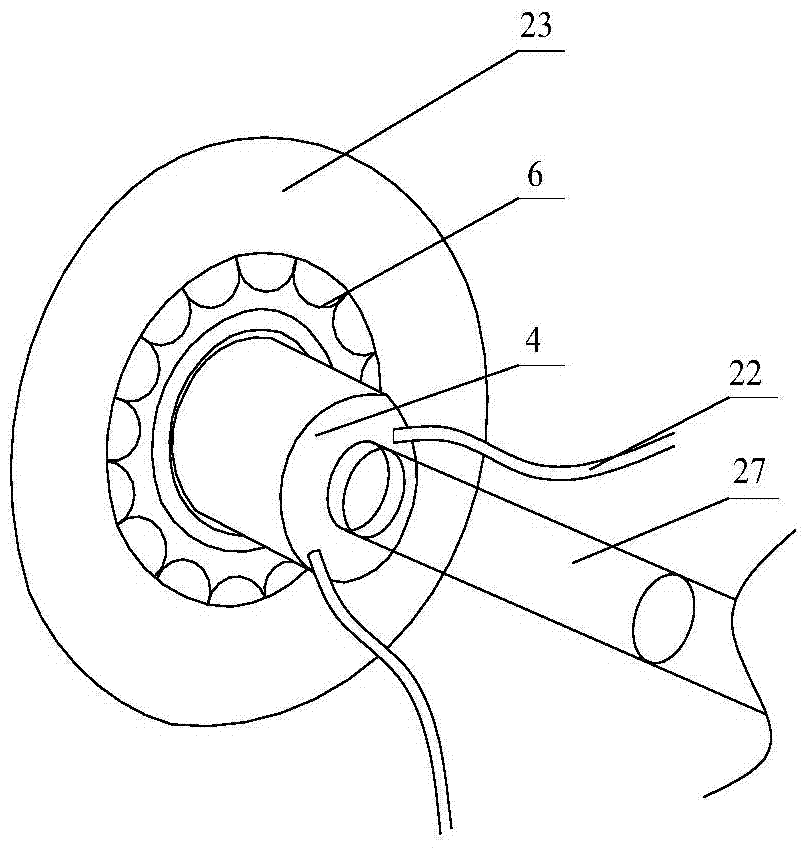

The invention discloses an optical fiber winding machine provided with a wire pressing wheel. The optical fiber winding machine comprises a rail (1), a tackle (2) and a traction device (3). The tackle (2) is arranged on the rail (1) in a sliding mode and connected with the traction device (3) through a stretching rod (4). The tackle (2) comprises a base (5) and a rotary shaft (6) installed on the base (5), and the rotary shaft (6) is driven to rotate through a rotating motor (7) installed on the base (5). The optical fiber winding machine has the advantages that a winding drum is driven by the motor to perform winding, only one traction device is adopted, the thickness of an optical fiber is sensed through a sensor, the transverse motion speed of the winding drum requiring traction is calculated so that the optical fiber can be evenly wound on the winding drum, thus, not only is a large amount of manpower saved, but also the optical fiber is distributed evenly and will not knot when being unwound, and the optical fiber is protected.

Owner:成都亨通光通信有限公司

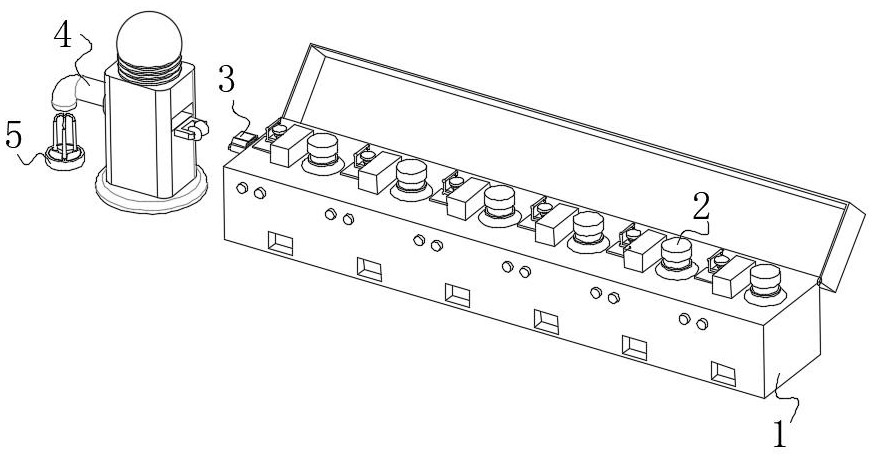

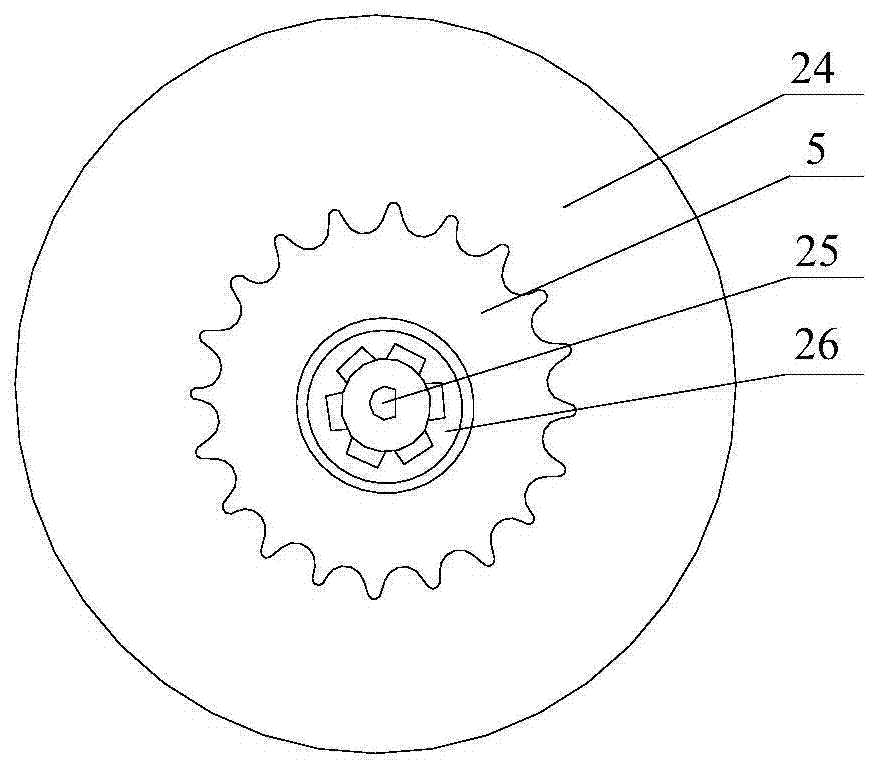

Multi-plug automatic winding displacement digital display power disc

ActiveCN104362473AMonitor voltage status in real timeReduce the risk of low voltage electric shockFlexible lead accommodationLow voltageVoltmeter

The invention discloses a multi-plug automatic winding displacement digital display power disc which comprises a rack body. The rack body is provided with an automatic winding displacement device, multifunctional pluggable type plugs, a digital display voltmeter, overheat protectors and a leakage protector. The automatic winding displacement device comprises a fixing shaft, a power disc body, two chain wheels, a chain, a reciprocating lead screw and a nut. The overheat protectors are all arranged in the power disc body. The multifunctional pluggable type plugs, the digital display voltmeter and the leakage protector are all arranged on the power disc body. The power disc body is arranged on the fixing shaft in a sleeving mode. The fixing shaft is sleeved with the first chain wheel, the second chain wheel is arranged at the end of the reciprocating lead screw, and the two chain wheels are in transmission through the chain. The reciprocating lead screw is sleeved with the nut, a cable guide mechanism is arranged below the nut, and the cable penetrates through the cable guide mechanism and then is wound on the power disc body. The multi-plug automatic winding displacement digital display power disc has the advantages of being capable of improving the take-up and pay-off efficiency of the power disc body, safe to use, high in reliability, capable of lowering the low voltage electric shock risks of workers and the like.

Owner:STATE GRID CORP OF CHINA +2

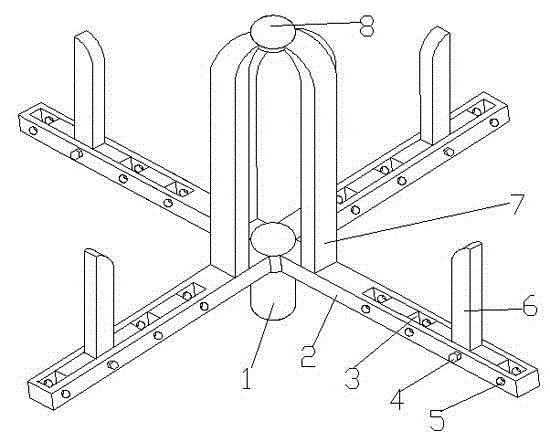

Coil storage device for silk thread spinning

PendingCN107161777AReasonable structureImprove the take-up effectFilament handlingEngineeringCantilever

The invention provides a coil storage device for silk thread spinning. The coil storage device comprises a main frame. Multiple sets of supporting beams are distributed on the main frame from top to bottom. Each supporting beam is composed of two fixed plates. The two fixed plates of the same set are located at the two ends of the main frame correspondingly. The middle of each fixed plate is fixedly connected with the main frame. The two ends of each fixed plate are suspended to form cantilevers. Two limiting shafts are mounted on each cantilever set. A clearance is reserved between the two limiting shafts on each cantilever set to form a supporting groove. A thread coil is put in each supporting groove. The two sides of each thread coil are supported and limited by the corresponding limiting shafts. A coil taking assembly is movably mounted on the limiting shaft located on the outer end of each cantilever. After the scheme is adopted, the structure is reasonable, the coil taking effect is good, and coil taking is simple and convenient.

Owner:湖州华艺盛丝绸文化有限公司

Auxiliary device for winding computer network cables

The invention relates to the technical field of computer auxiliary equipment and discloses an auxiliary device for winding computer network cables. The auxiliary device comprises a base, wherein a sliding groove is formed in the surface of the base; a magnet I is arranged on the surface of the base; a magnet II is arranged on the surface of the base; support frames are arranged in the base; a rotating shaft is arranged in the support frames; and one end, away from the magnet II, of the rotating shaft is movably connected with a magnetic block. According to the auxiliary device for winding computer network cables, the magnet I and the magnet II cooperate with induction coils in use, the support frames cooperate with a rack in use, and a screw cooperates with current commutators in use; a cable winding shaft is capable of circularly moving left and right when winding the network cables, so that the network cables are wound more uniformly; the cable winding effect is improved; no manual coordination is needed; and the cable winding efficiency is improved.

Owner:湖南顺一鑫电子科技有限公司

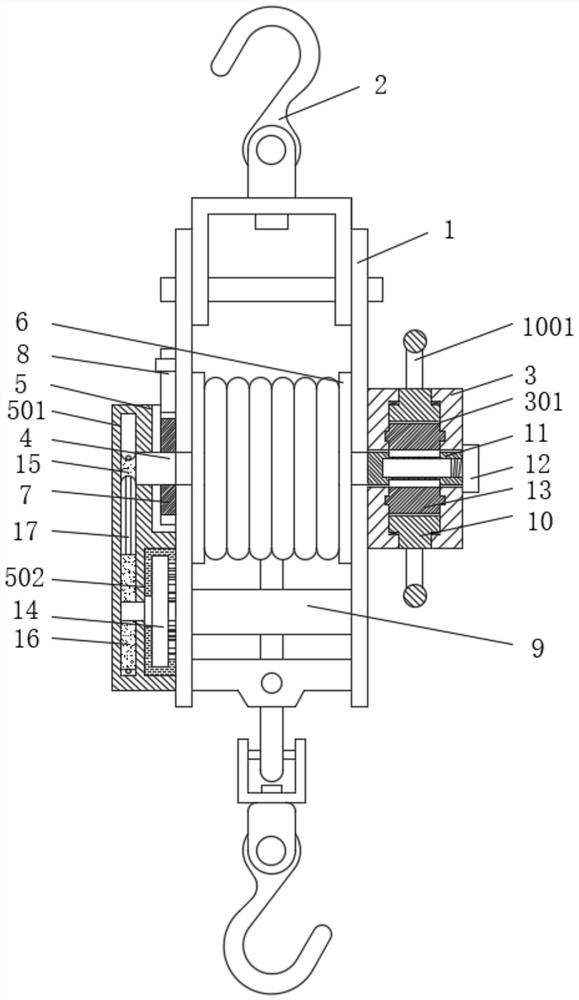

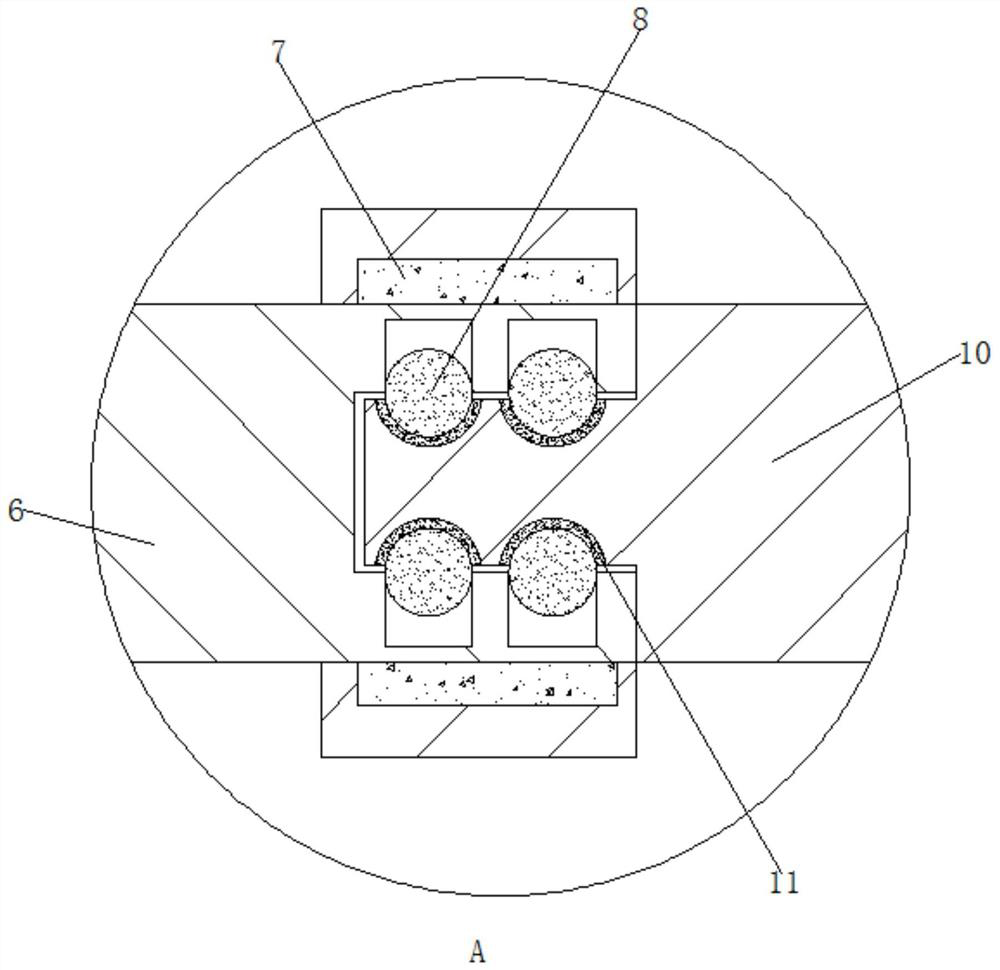

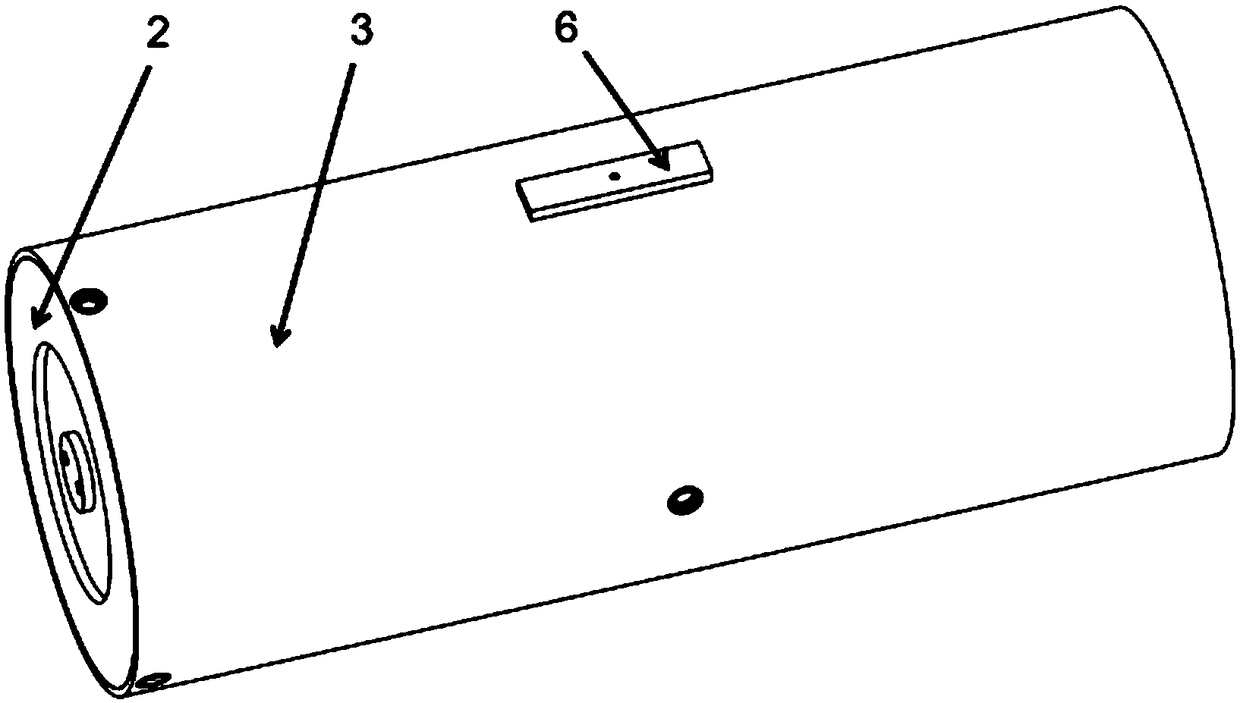

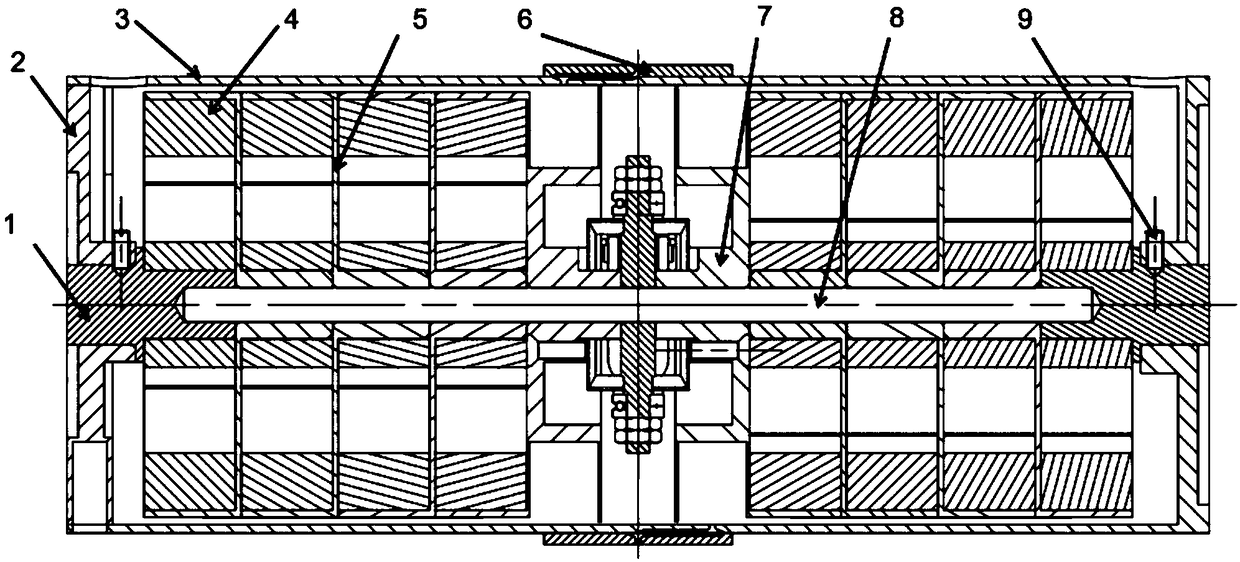

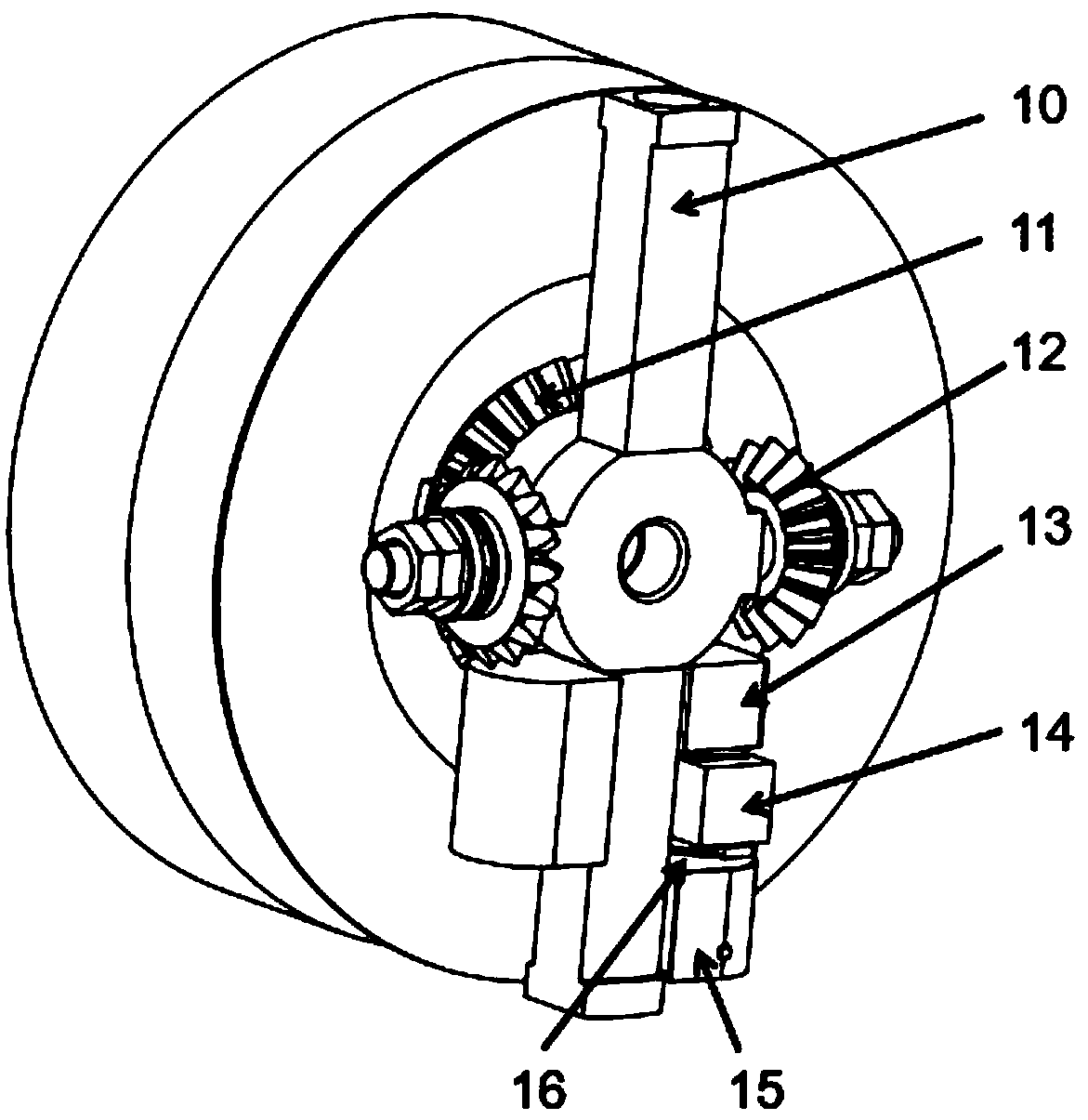

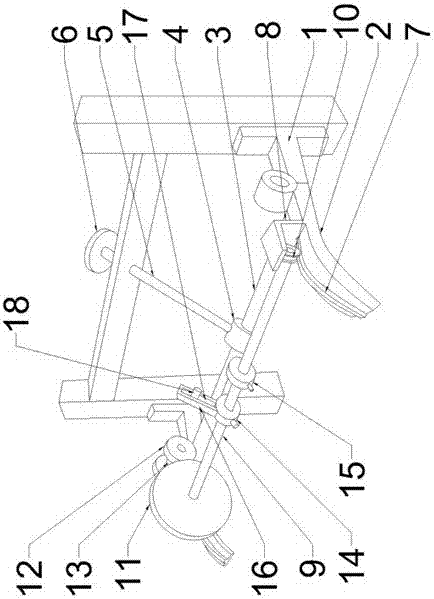

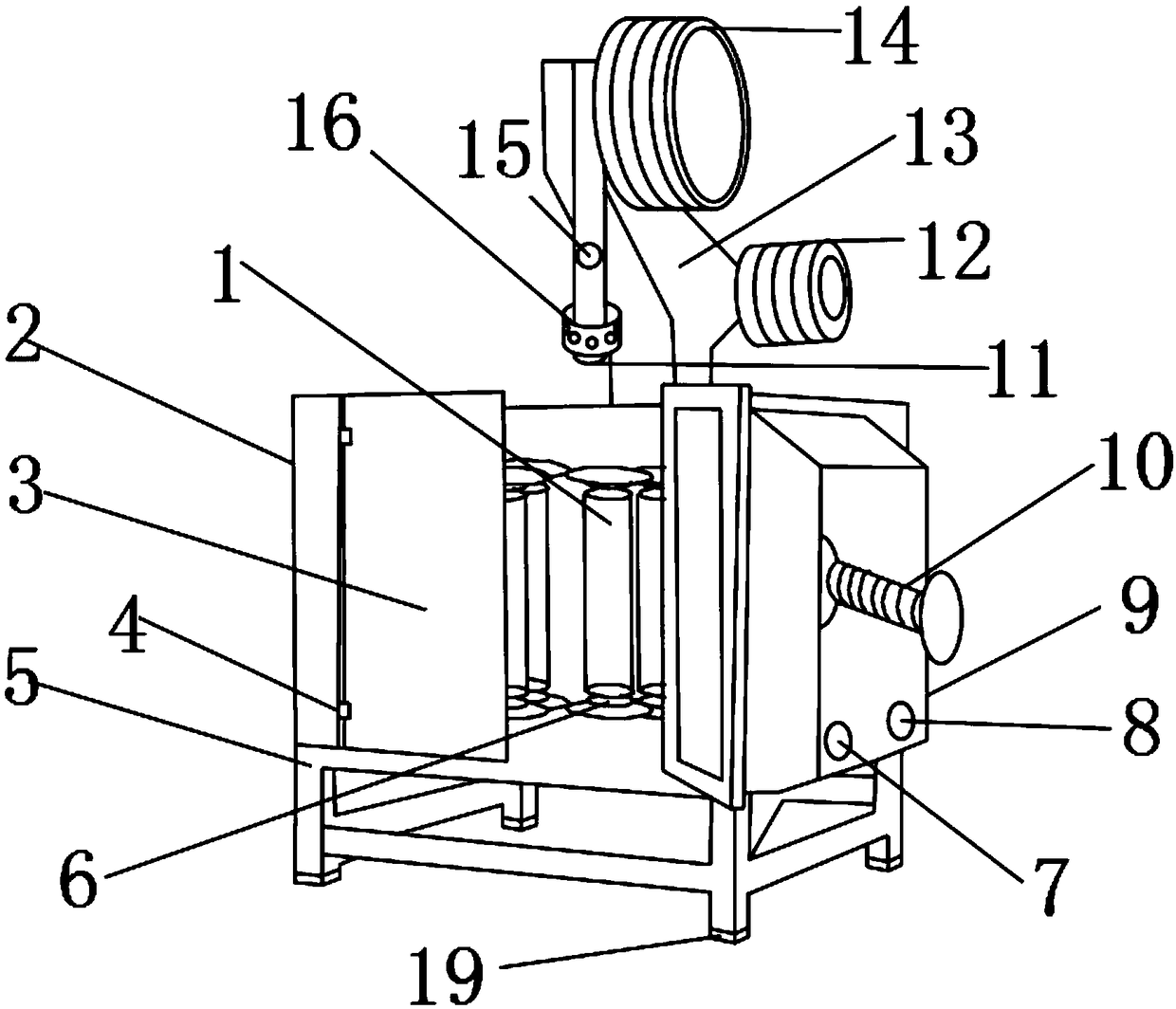

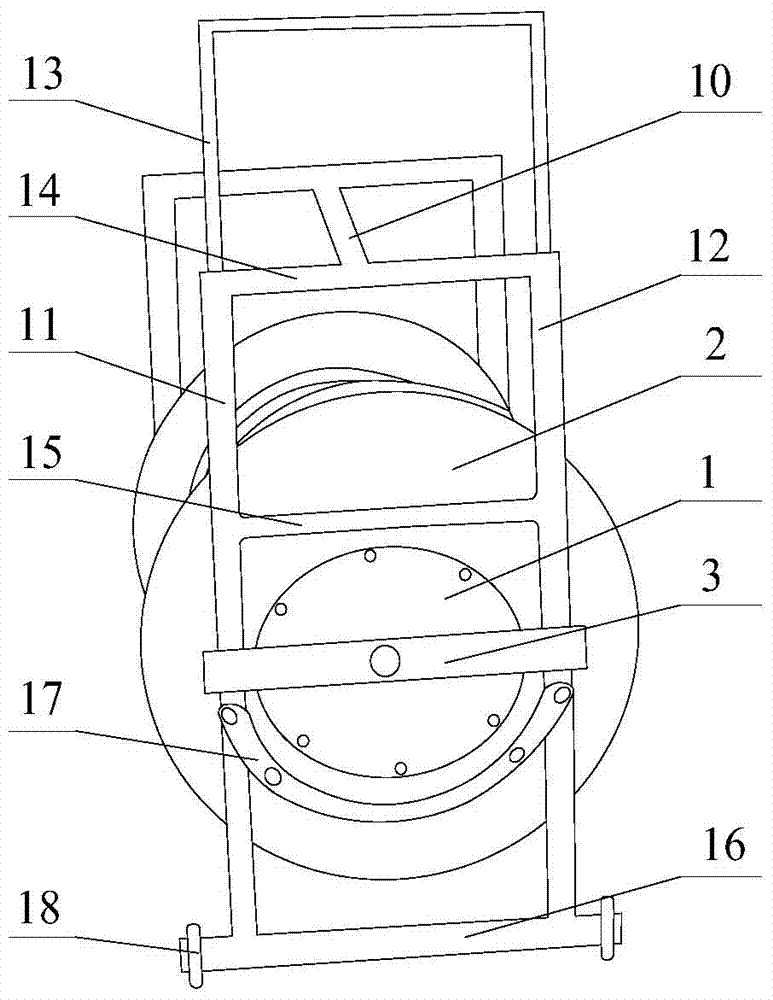

A spring accumulator type flying net retracting device

The invention provides a spring accumulator type flying net retracting device which belongs to the technical field of aerospace. The device comprises a series type clockwork energy storage mechanism,a rope pulley collecting mechanism, a synchronous gear mechanism, a trigger locking mechanism, a shell, a control circuit, and the like. The series type clockwork energy storage mechanism includes a spring shaft, a spring and a middle wheel. The rope pulley collecting mechanism includes a rope collecting outlet guide plate, rope pulleys and a spindle. The synchronous gear mechanism comprises a bevel gear carrier, a large bevel gear and a small bevel gear. The trig and locking mechanism comprises a spring box, a clamping block, a clamping cover, a push-pull electromagnet and a return spring. When the upper string is wound, the electromagnet is not energized, the clamping block restricts the rotation of the rope pulleys, loosens the development bar locking screw, and completes the manual winding. The control circuit board energizes the electromagnet, the clamping block retracts, and the rope pulleys rotate to take up the rope under the spring force of the spring, so as to trigger the rope pulley. The two rope pulleys are synchronously reversed to realize take-up. Locking is performed after take-up is completed, take-up is finished, the clamping block is reset and the rope pulleys arere-locked.

Owner:UNIV OF SCI & TECH BEIJING

Wool yarn take-up device

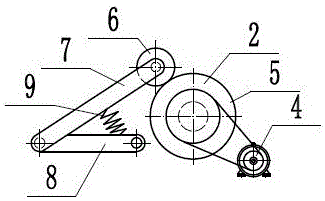

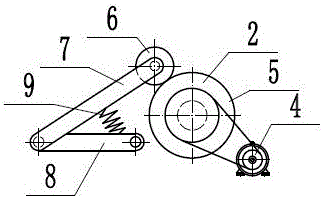

InactiveCN105088432ASwing back and forthIt has the following advantages and effects: the take-up mechanism can swing back and forthContinuous wound-up machinesYarnEngineering

The invention provides a wool yarn take-up device and belongs to the technical field of textile machinery. The wool yarn take-up device comprises a take-up mechanism and a swing mechanism. A guide roll of the take-up mechanism is arranged on a rack in a rotating mode. Yarn guide grooves are formed in the guide roll at equal intervals. A yarn take-up support is arranged on the rack in front-rear sliding mode. One end of a bearing support is fixed to the yarn take-up support. The other end of the bearing support is hinged to the lower end of a take-up roll support. A take-up roll is arranged at the upper end of the take-up roll support in a rotating mode and is tightly attached to the guide roll under the action of a pressure spring. A first belt wheel of a drive mechanism is concentrically arranged on one side of the guide roll. The first belt wheel and a second belt wheel are connected through a drive belt. The second belt wheel is coaxially connected with a drive motor. One end of a connection rod of the swing mechanism is hinged to one end of the yarn take-up support. The other end of the connection rod is hinged to one end of a crank. The other end of the crank is connected with a swing motor. The wool yarn take-up device is uniform in take-up, good in effect, simple in structure and low in cost.

Owner:NANTONG DOUBLE GREAT TEXTILE

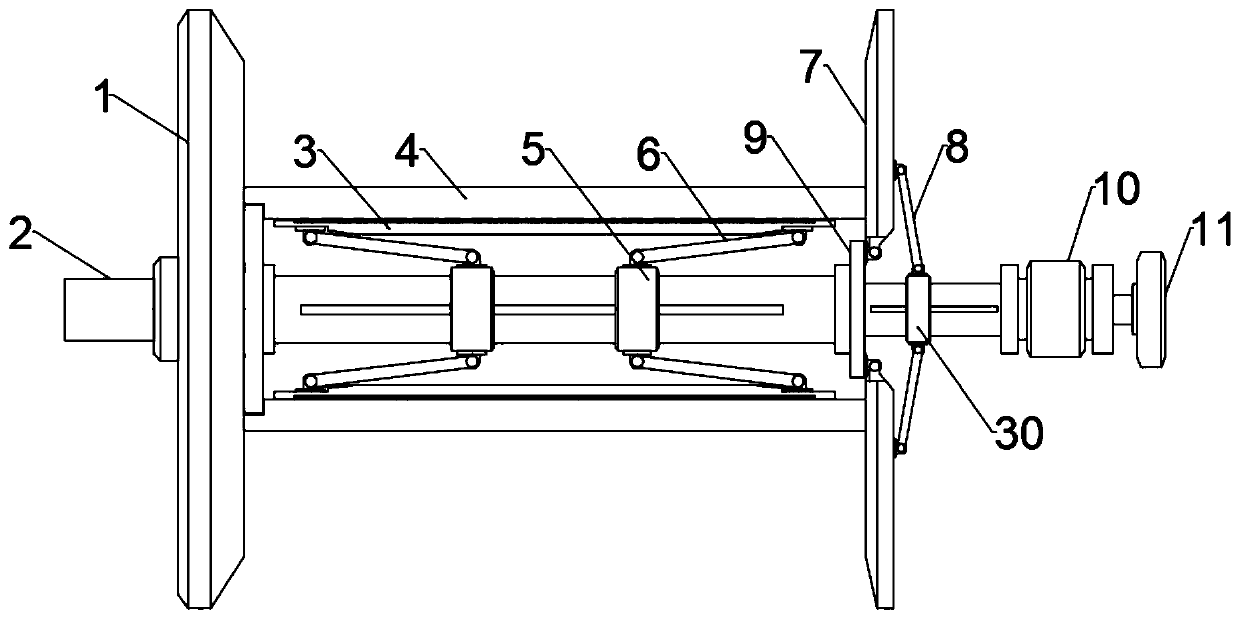

Winding mechanism for doubling machine

The invention provides a winding mechanism for a doubling machine. The winding mechanism comprises fixing bases, a supporting arm is movably hinged to each fixing base, the inner ends of the two supporting arms are fixedly connected through a synchronizing shaft, the middle portion of the synchronizing shaft is sleeved with a lifting sleeve, a guide face is arranged at the outer end of the supporting arm, guide ribs are arranged on the guide face, a limiting block is arranged at the inner end of the guide face, and guide wheels are arranged at the two ends of a winding shaft and are supported through the guide face; a winding tooth disc is arranged at one end of the winding shaft, a transmission shaft is arranged at the inner end of one supporting arm, a driving wheel is arranged at one end of the transmission shaft and is connected with a power mechanism in the doubling machine, and the other end of the transmission shaft is provided with a transmission tooth disc; and the transmission tooth disc is meshed with the winding tooth disc, the winding shaft is movably sleeved with a first positioning ring and a second positioning ring, a winding sleeve is movably arranged on the winding shaft in a sleeving manner, a lock plate is fixed to one side of the first positioning ring, a lock groove is formed in the lock plate, and a sleeve locking bolt is arranged on the lock groove. The winding mechanism adopting the scheme is reasonable in structure, good in maneuverability, stable in running and good in winding effect.

Owner:长兴博美纺织有限公司

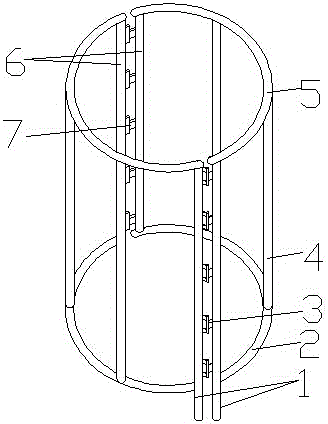

Copper line take-up reel opening and closing reinforcement device

ActiveCN104409174AGood take-up effectAvoid being stretched or even brokenCable/conductor manufactureCopper wireStructural engineering

The invention discloses a copper line take-up reel opening and closing reinforcement device, belonging to the field of mechanical processing equipment. The device includes a take-up roller, a bottom round rod, a top round rod, a rotating fixed rod and a connecting rod, and the bottom round rod and the top round rod are concentric circles and have the same diameter, and are fixed connected through the take-up roller. The bottom round rod and the top round rod define two openings along the diameter line, and one opening is located at the bottom round rod and the top round rod, so each of the bottom round rod and the top round rod is respectively fixed to the rotating fixed rod; the other opening is located at the bottom round rod and the top round rod, respectively fixed to the connecting rod. Two rotating fixed rods are connected by a hinge, and two connecting rods are connected by a lock catch. The reinforcement device can realize a large number of cable winding one-time and can avoid the cable from bondage and messy of the emergence of a large number of winding horizontal, especially the copper wire with larger single weight and elongation and smaller tensile property has better winding effect, which can ensure uniform take-up and unable to stretch.

Owner:WUHU CHANGRUN SPECIAL COPPER

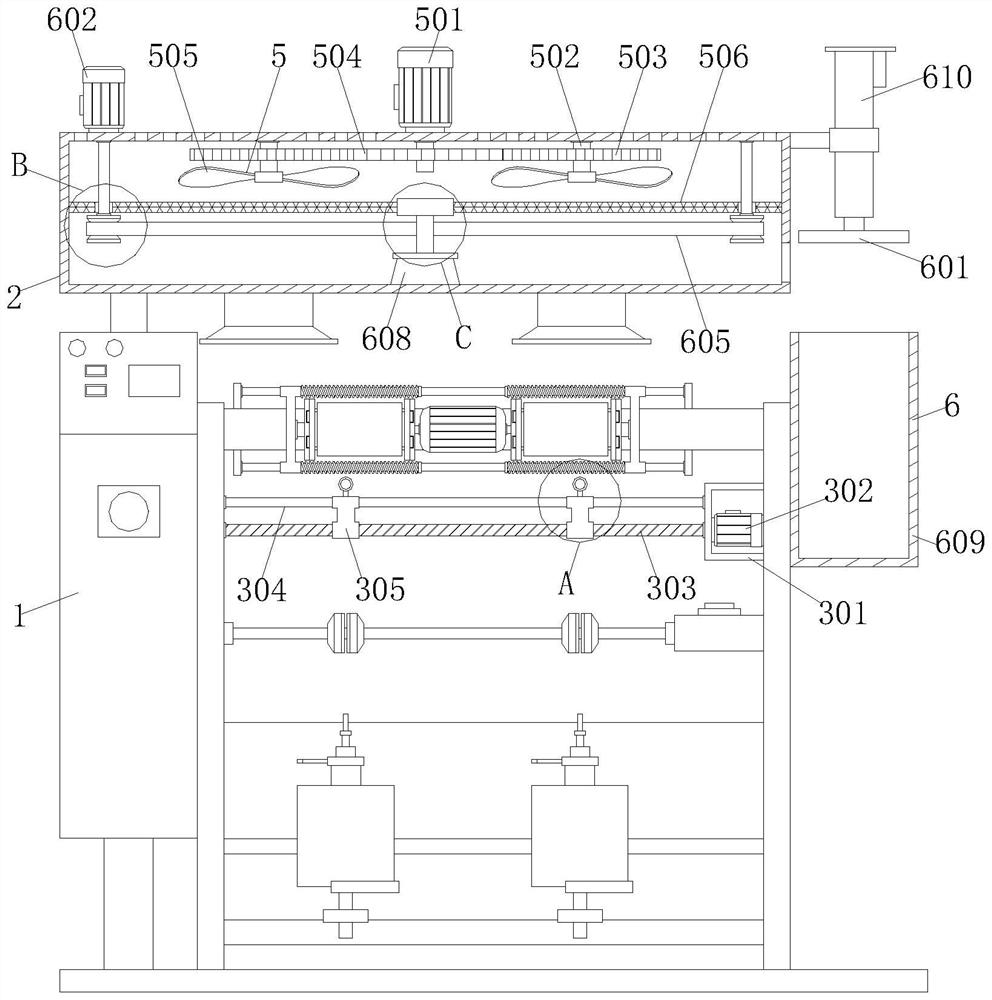

Winding device for photovoltaic welding strip typesetting machine

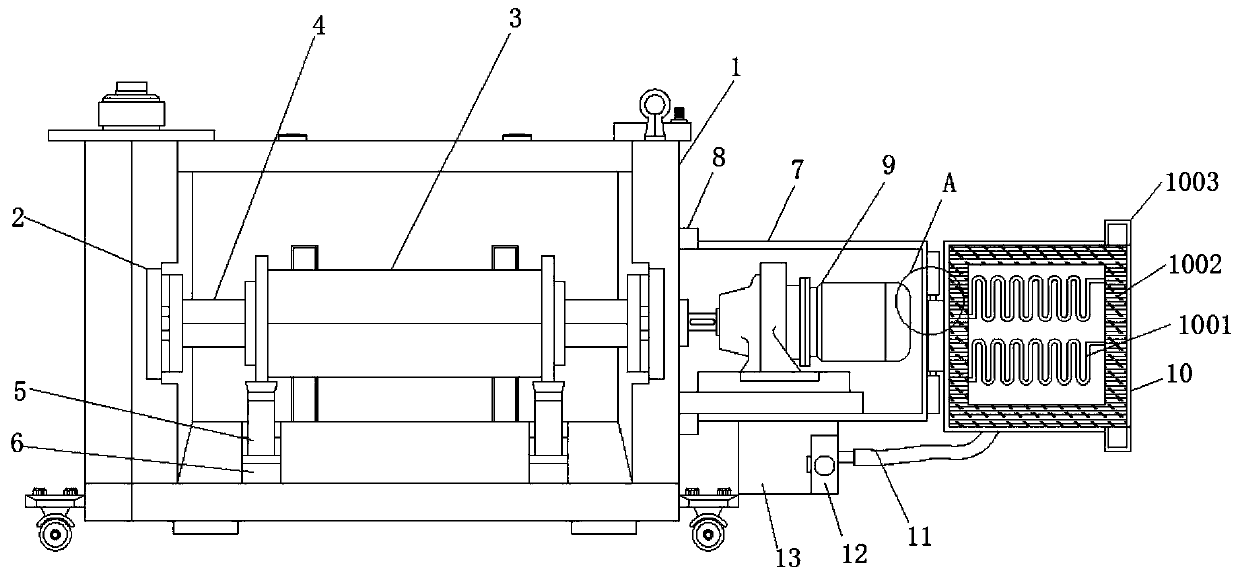

PendingCN111112379AEasy to operateEasy maintenanceFinal product manufactureCooling/ventillation arrangementElectric machineWorking environment

The invention discloses a winding device for a photovoltaic welding strip typesetting machine. The device comprises a main body and a connecting pipe, wherein adjusting devices are arranged at the twoends of the interior of the main body correspondingly, connecting shafts are arranged at one ends of the exteriors of the adjusting devices, a winding barrel is arranged at one ends of the exteriorsof the connecting shafts, supporting frames are arranged at the bottom of the winding barrel, sliding ways are arranged at the exteriors the bottoms of the supporting frames, one end of the exterior of the main body is connected with a protecting frame, and a motor is arranged in the protecting frame. According to the winding device for the photovoltaic welding strip typesetting machine, through the arrangement of a protecting device comprising cooling pipes, attracting cottons and tenon blocks, heat emitted when a motor works can be dissipated in time in the long-time using process, the situation that the heat is accumulated in the protecting frame and cannot be dissipated is avoided, and the load capacity of the motor in the using process can be reduced to a certain extent; and noise generated when the motor works can be reduced in the using process, so that the working environment is kept in a relatively comfortable state.

Owner:英利能源(江西)有限公司

An adjustable opening and closing reinforcement device for a copper wire take-up reel

The invention discloses an adjustable opening / closing reinforcing device for a copper cable reeling disc and belongs to the field of mechanical processing equipment. The device comprises a reeling roller, a bottom round rod, a top round rod, two rotary fixing rods and two connecting rods, wherein the bottom round rod and the top round rod are fixedly connected through the reeling roller and are concentric circles; rotating pairs are arranged on both the top round rod and the bottom round rod; two end openings are formed in the bottom round rod and the top round rod along a diameter line; the rotary fixing rods are fixed at one end openings; the connecting rods are fixed at the other end openings; the two rotary fixing rods are connected through a hinge; the two connecting rods are connected through a locking buckle; the locking buckle comprises a movable part and a fixed part. A large number of cables can be reeled by the device at one time; the phenomena that the cables are unbound and are in a mess when the cables are reeled in a large number are avoided; the reeling effect on the copper cables with relatively high unit weight, relatively high product elongation percentage and relatively low tensile property is particularly better; uniform cable reeling is guaranteed; the cables are guaranteed not to be stretched.

Owner:WUHU CHANGRUN SPECIAL COPPER

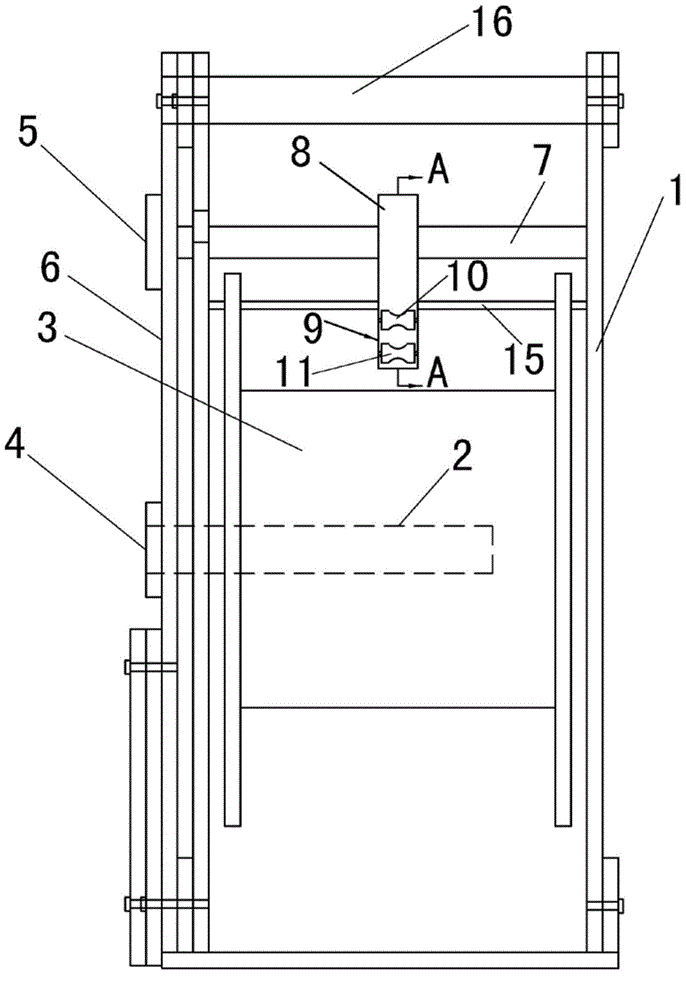

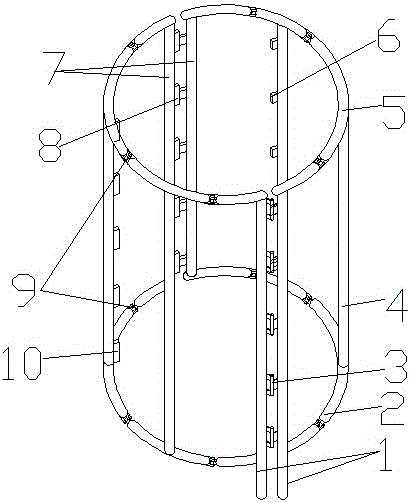

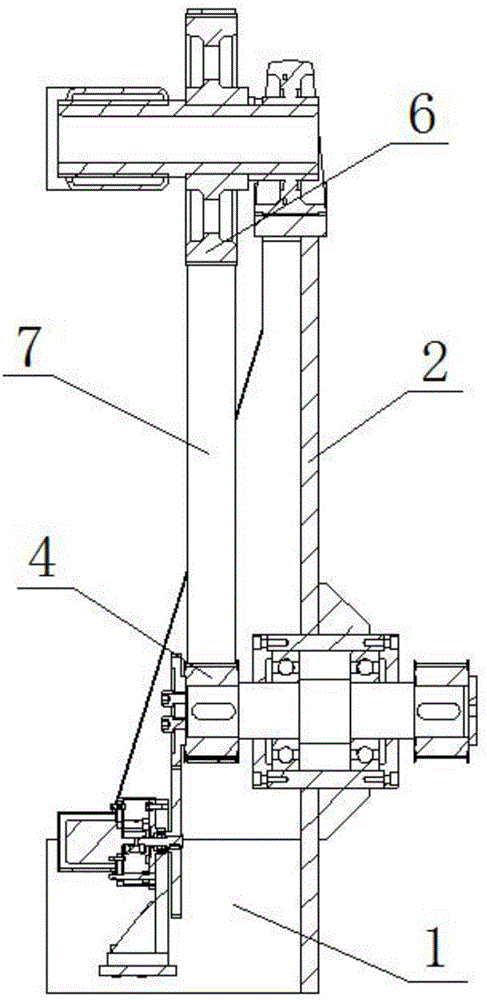

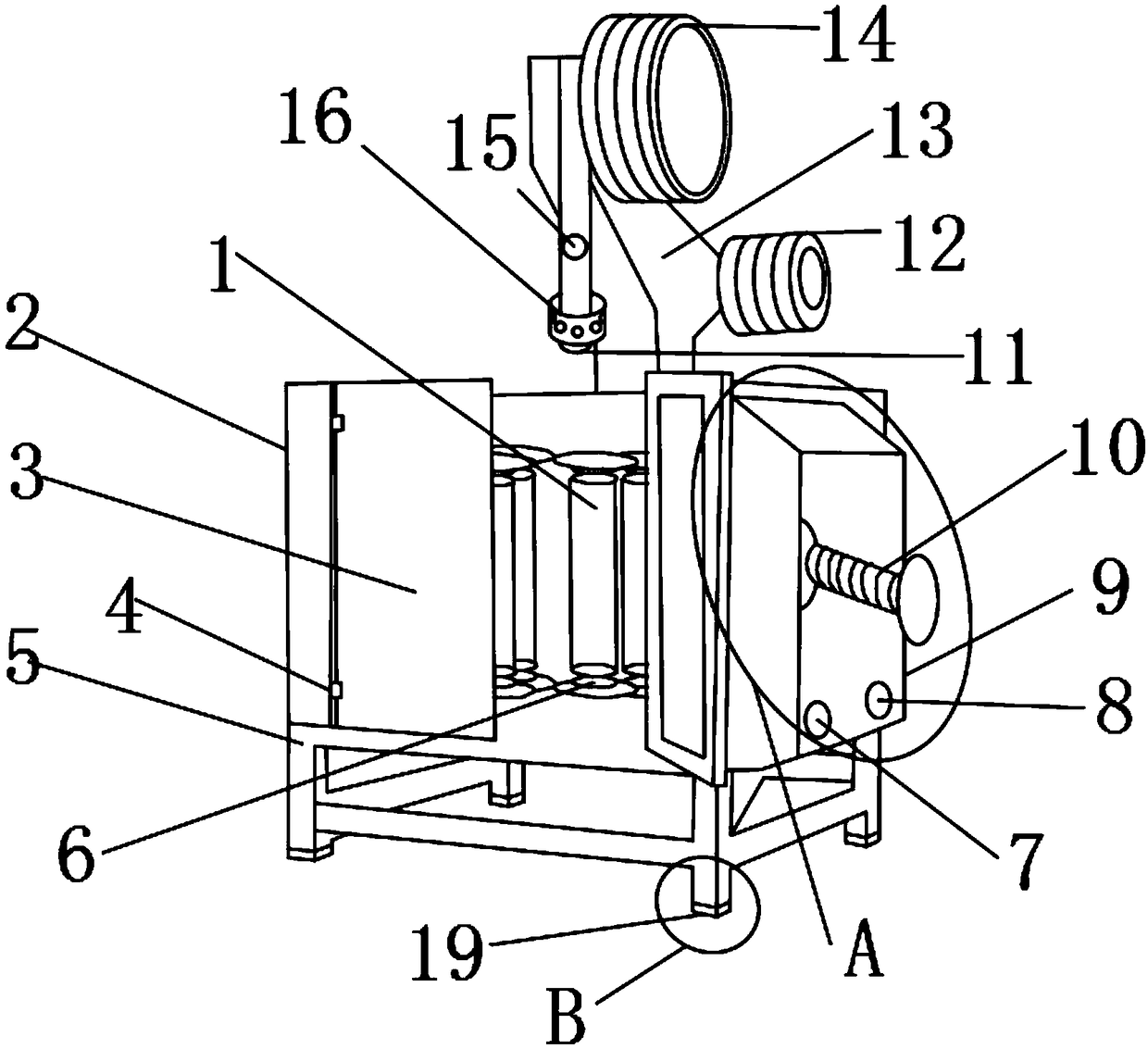

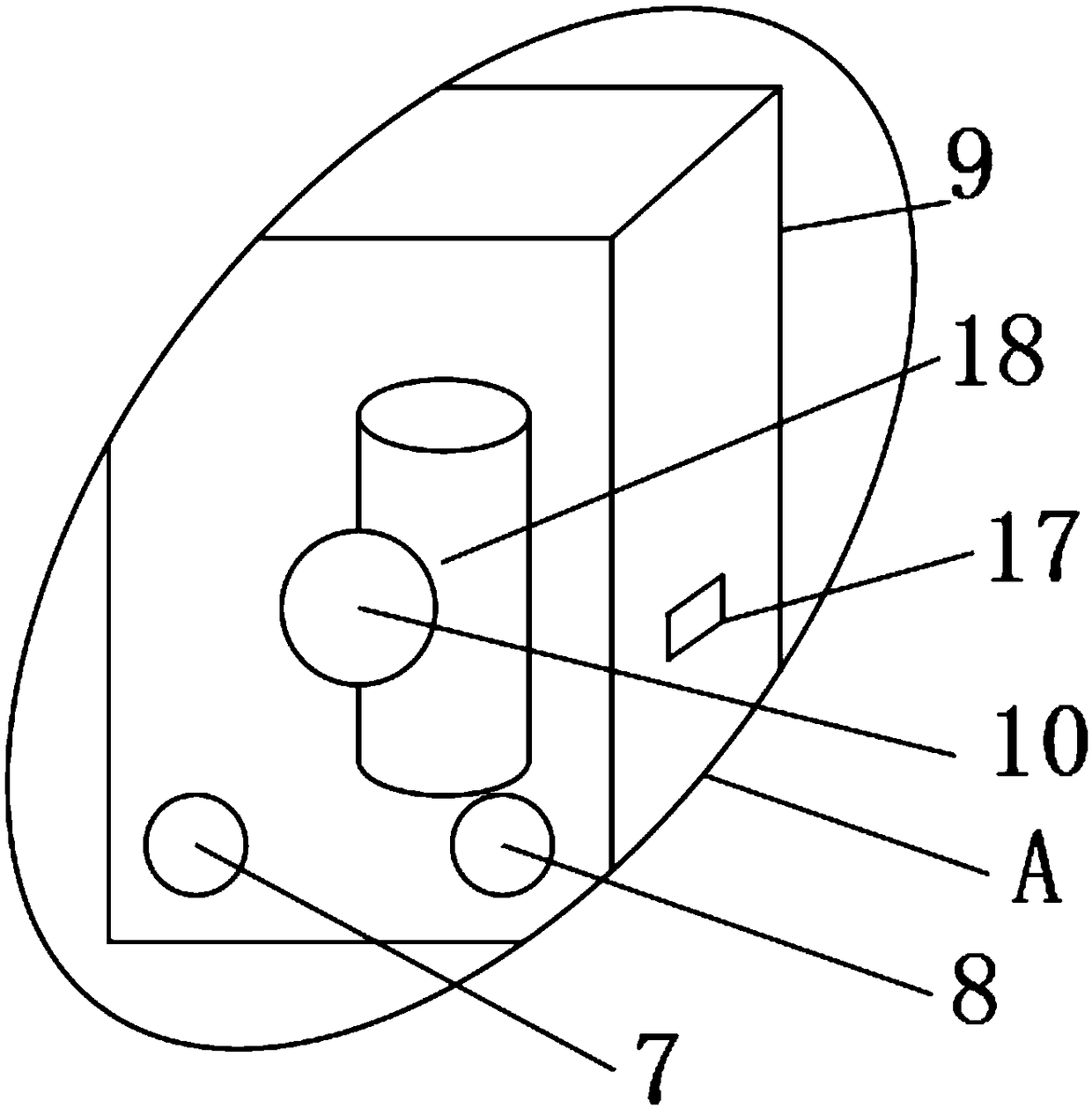

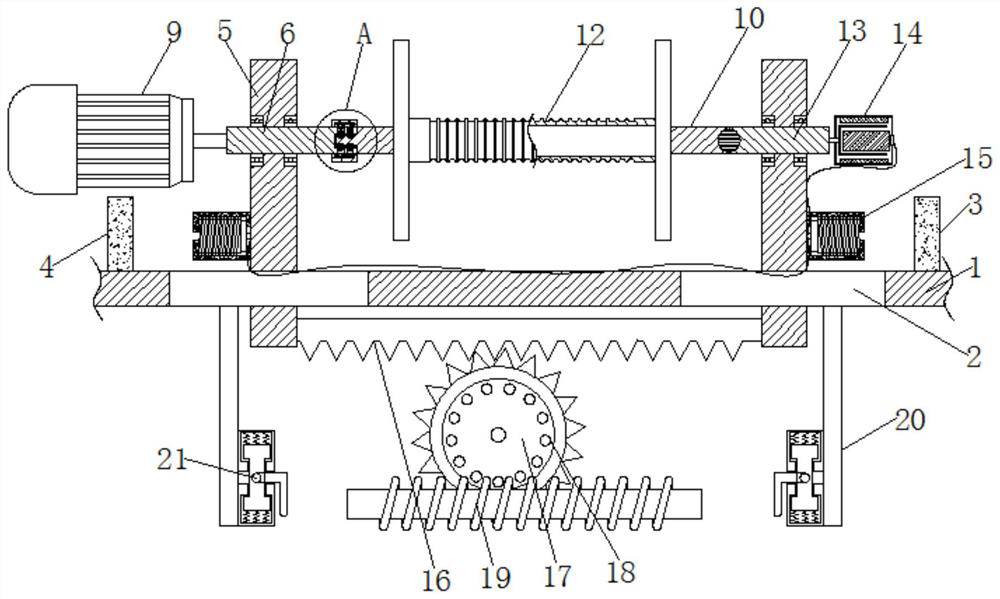

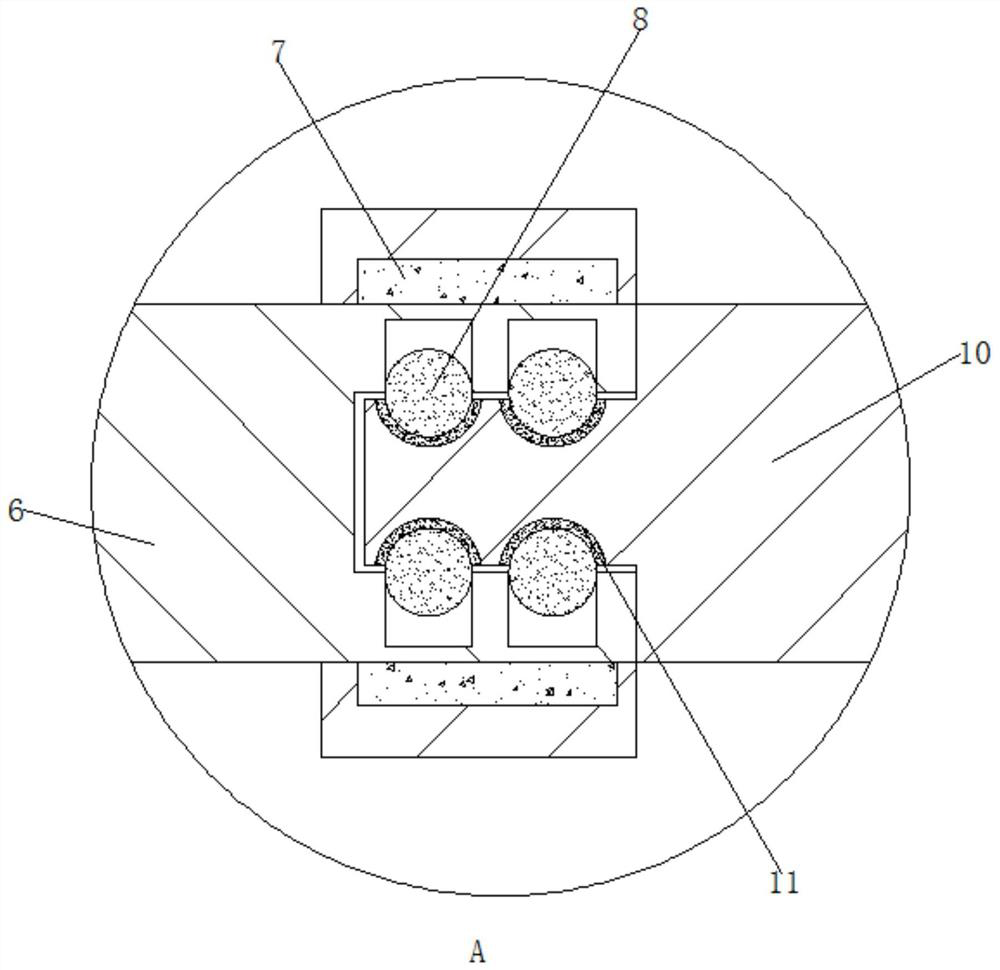

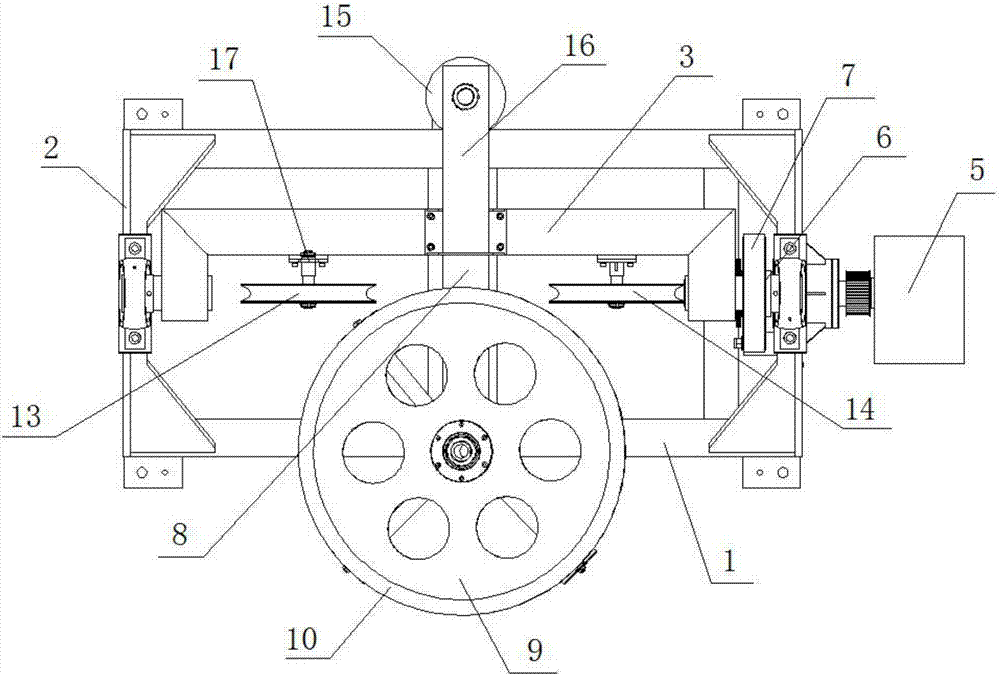

Isolation apparatus for drum-twisting crawling traction type cable former

ActiveCN106205882ATension does not affectImprove work efficiencyCable/conductor manufactureIsolation effectEngineering

The invention discloses an isolation apparatus for a drum-twisting crawling traction type cable former. The isolation apparatus comprises a rectangular bottom frame, wherein two opposite side plates are arranged at the two ends of the rectangular bottom frame; a U-shaped bracket which is connected with the side plates in a rotatable manner is arranged between the top parts of the two side plates; a guide roller is connected on one side of the U-shaped bracket through a guide wheel bracket; a first guide wheel and a second guide wheel are arranged on the two sides of the guide wheel bracket; the first guide wheel and the second guide wheel are flush with each other; and the first guide wheel is positioned above the second guide wheel. The isolation apparatus adopts a one-way guide wheel structure to wind a cable which enters the isolation apparatus; the guide roller is rotated passively; a cable shifting wheel is adopted for cable shifting on the outer side; the guide wheels are mounted on the front and back sides, so that center consistency is ensured; when a wire-collecting drum and a wire-releasing frame are not consistent in tension caused by redundant length, an isolation effect is played, so that it is ensured that the wire-releasing frame tension and the wire-collecting drum tension are not affected mutually; and meanwhile, the overall isolation apparatus adopts a wheel type rotary mechanism, and is driven to rotate through a transmission band, and rotates synchronously with the wire-collecting drum, so that the working efficiency and the wire-collecting effect of the cable former are effectively improved.

Owner:HEFEI SMARTER TECH GROUP CORP

Shaft beating device for doubling of polyester yarns

The invention discloses a shaft beating device for doubling of polyester yarns. The shaft beating device comprises a device main body and a motor cabinet, wherein a support is arranged at the upper end of the device main body, a first frosted threaded wheel is arranged on one side of the support, a second frosted threaded wheel is arranged on the other side of the support, a wire outlet hole is formed in the lower portion of the second frosted threaded wheel, a porous doubling machine is arranged below the wire outlet hole, and a winding drum sleeve rod is arranged on the outer surface of themotor cabinet. According to the shaft beating device for doubling of the polyester yarns, the winding drum sleeve rod, the porous doubling machine and a rubber cushion layer are arranged, so that doubling of the plurality of polyester yarns can be realized simultaneously in the operation process of the device main body, and the yarns which are doubled wind around the winding drum sleeve rod for rolling through the operation of the frosted wheels; and in addition, when the device operates, the stability of the device main body is improved, the high-quality production of products is guaranteed,the device is suitable for different working conditions, and a better application prospect is brought.

Owner:JIAXING WEITELA ELECTRICAL SCI & TECH CO LTD

A computer network cable take-up auxiliary device

ActiveCN111847105BTake up evenlyImprove the take-up effectFilament handlingComputer-aidedControl theory

The present invention involves the technology field of computer auxiliary equipment, and has disclosed a computer -based network cable closing auxiliary device, including the base, which is opened on the surface of the base.Set up with a magnet two, the internal setting of the base is set with a bracket, the internal setting of the bracket is set with a rotor shaft, which is connected to a magnetic block from one end of the one -end of the rotating shaft.The coordination of the shaft and the branches, from the combination of the axis shaft and the induction magnet, the combination of the magnetic one and the magnet two and the inductive coil, the combination of brackets and racksWhen the wire shaft is closed on the network cable, it can be moved left and right to make the closing line of the network cable more uniform, which improves the line collection effect. No manual cooperation is required to improve the line efficiency.

Owner:湖南顺一鑫电子科技有限公司

Adjustable opening/closing reinforcing device of copper cable reeling disc

The invention discloses an adjustable opening / closing reinforcing device for a copper cable reeling disc and belongs to the field of mechanical processing equipment. The device comprises a reeling roller, a bottom round rod, a top round rod, two rotary fixing rods and two connecting rods, wherein the bottom round rod and the top round rod are fixedly connected through the reeling roller and are concentric circles; rotating pairs are arranged on both the top round rod and the bottom round rod; two end openings are formed in the bottom round rod and the top round rod along a diameter line; the rotary fixing rods are fixed at one end openings; the connecting rods are fixed at the other end openings; the two rotary fixing rods are connected through a hinge; the two connecting rods are connected through a locking buckle; the locking buckle comprises a movable part and a fixed part. A large number of cables can be reeled by the device at one time; the phenomena that the cables are unbound and are in a mess when the cables are reeled in a large number are avoided; the reeling effect on the copper cables with relatively high unit weight, relatively high product elongation percentage and relatively low tensile property is particularly better; uniform cable reeling is guaranteed; the cables are guaranteed not to be stretched.

Owner:WUHU CHANGRUN SPECIAL COPPER

A vertical adjustable take-up reel

ActiveCN104464953BImprove adjustabilityAvoid being stretched or even brokenFilament handlingCable/conductor manufactureScrew threadMachining

The invention discloses a vertical adjustable wire take-up reel, which belongs to the field of mechanical processing equipment. It includes a rotating shaft and a take-up chassis. The take-up chassis includes a limit roller and a take-up roller, and there are 3-6, all fixed on the top of the rotating shaft. The limit roller includes a roller sleeve and a roller rod, and the roller sleeve is covered with a roller. rod, and the same side is provided with a second threaded hole, and is fixed by a second screw; the upper end surface of the take-up chassis is fixed with a take-up roller and a groove, and a roller sleeve is arranged in the groove, and passes through the groove on the side of the take-up chassis. The groove is provided with a first threaded hole, and when the roller sleeve is placed in the groove, a threaded hole is also provided at the corresponding position of the first threaded hole, and is fixed by the first screw. The present invention realizes the adjustability of the distance between the take-up roller and the limit roller and the overall height of the limit roller through the limit roller provided on the upper end surface of the take-up chassis, so it can be used for coils of different sizes and heights. The winding is realized, and the limit roller can also avoid the phenomenon that the cable will not be unbound and messy in the horizontal direction when a large amount of winding is performed.

Owner:WUHU CHANGRUN SPECIAL COPPER

Isolation device of a coiled crawler traction type cable forming machine

ActiveCN106205882BTension does not affectImprove work efficiencyCable/conductor manufactureIsolation effectCable machine

Owner:HEFEI SMARTER TECH GROUP CORP

A straight-forward wire drawing machine that can automatically and conveniently take up wires

ActiveCN113680841BEasy to useAdjust the wrapping rangeElectrical and Electronics engineeringWire drawing

The invention belongs to the field of wire drawing machines, and specifically relates to a straight-forward wire drawing machine that can automatically and conveniently take up wires, including a main body; Flexible connection, the left end of the main body is provided with a guide mechanism, the right end of the guide mechanism is fixedly connected with the left end of the main body, the left end of the guide mechanism is provided with a take-up mechanism, the bottom of the take-up mechanism is provided with a take-up rack, and the take-up The bottom of the mechanism is in contact with the top of the take-up rack, the pulling head includes a movable column, the top of the movable column is provided with a rotating column, and the top of the movable column is movably connected with the bottom of the rotating column, and the rotating column A clamping plate is provided inside, and the inner wall of the rotating column is in contact with the outer surface of the clamping plate, the top of the clamping plate is provided with a positioning column, and the top of the clamping plate is fixedly connected to the bottom of the positioning column, and the positioning The top of the column is provided with an extruded plate.

Owner:上海群乐船舶附件启东有限公司

A yarn take-up device

The invention provides a wool yarn take-up device and belongs to the technical field of textile machinery. The wool yarn take-up device comprises a take-up mechanism and a swing mechanism. A guide roll of the take-up mechanism is arranged on a rack in a rotating mode. Yarn guide grooves are formed in the guide roll at equal intervals. A yarn take-up support is arranged on the rack in front-rear sliding mode. One end of a bearing support is fixed to the yarn take-up support. The other end of the bearing support is hinged to the lower end of a take-up roll support. A take-up roll is arranged at the upper end of the take-up roll support in a rotating mode and is tightly attached to the guide roll under the action of a pressure spring. A first belt wheel of a drive mechanism is concentrically arranged on one side of the guide roll. The first belt wheel and a second belt wheel are connected through a drive belt. The second belt wheel is coaxially connected with a drive motor. One end of a connection rod of the swing mechanism is hinged to one end of the yarn take-up support. The other end of the connection rod is hinged to one end of a crank. The other end of the crank is connected with a swing motor. The wool yarn take-up device is uniform in take-up, good in effect, simple in structure and low in cost.

Owner:NANTONG DOUBLE GREAT TEXTILE

Copper wire take-up reel opening and closing reinforcing device

The invention discloses an opening and closing reinforcement device for a copper wire take-up reel, which comprises a fixed shaft, and a roller is sleeved on the fixed shaft, and both ends of the roller are provided with a plurality of arc-shaped grooves along the circumferential direction. An arc-shaped block is arranged in the arc-shaped groove, and the arc-shaped block is fixed inside the arc-shaped cavity by a locking screw. One end of the arc-shaped block is provided with a fixed rod, and the fixed rod is threadedly connected with the arc-shaped block. The end of the fixing rod away from the arc-shaped block passes through the side wall of the arc-shaped groove and is connected to the limiting plate. The invention has reasonable structural design and simple operation, and can realize winding of a large number of cables at one time, and can avoid the phenomenon that the cables will not be released from the shackles and disorderly in the horizontal direction during a large number of windings, especially for products. Copper wires with larger weight per room, higher product elongation and lower tensile properties have better winding effect, ensuring uniform winding without being stretched.

Owner:盐城市奇翔铜业有限公司

A copper wire take-up reel opening and closing reinforcement device

ActiveCN104409174BEasy windingNo escape from bondageCable/conductor manufactureCopper wireEngineering

The invention discloses a copper line take-up reel opening and closing reinforcement device, belonging to the field of mechanical processing equipment. The device includes a take-up roller, a bottom round rod, a top round rod, a rotating fixed rod and a connecting rod, and the bottom round rod and the top round rod are concentric circles and have the same diameter, and are fixed connected through the take-up roller. The bottom round rod and the top round rod define two openings along the diameter line, and one opening is located at the bottom round rod and the top round rod, so each of the bottom round rod and the top round rod is respectively fixed to the rotating fixed rod; the other opening is located at the bottom round rod and the top round rod, respectively fixed to the connecting rod. Two rotating fixed rods are connected by a hinge, and two connecting rods are connected by a lock catch. The reinforcement device can realize a large number of cable winding one-time and can avoid the cable from bondage and messy of the emergence of a large number of winding horizontal, especially the copper wire with larger single weight and elongation and smaller tensile property has better winding effect, which can ensure uniform take-up and unable to stretch.

Owner:WUHU CHANGRUN SPECIAL COPPER

Two-for-one twister for processing artificial environment-friendly fiber yarn

InactiveCN114855316AQuality improvementImprove firm performanceDispersed particle filtrationTextile disintegration and recoveryYarnFiber

The invention discloses a two-for-one twister for processing artificial environment-friendly fiber yarn, and relates to the technical field of two-for-one twisters. The two-for-one twister for processing the artificial environment-friendly fiber yarn comprises a two-for-one twister body, a dust collection mechanism and a dust collection mechanism, a filter box is fixedly installed at the top of the two-for-one twister body through a fixing block, an air inlet pipe is fixedly connected to the front side of the filter box and communicates with the interior of the filter box, and the dust collection mechanism comprises a rotating rod A and induced draft fan blades which are arranged in the filter box; one ends of the three groups of rotating rods A are rotationally mounted on the top of the inner side of the filter box, and the tops of the two groups of induced draft fan blades are fixedly connected with the other ends of the two groups of rotating rods A respectively. According to the two-for-one twister for artificial environment-friendly fiber yarn processing, through cooperative use of a direct current motor, a rotating rod A, a driven gear, a driving gear, induced draft fan blades and a filter screen, air around the two-for-one twister can be sucked into the filter box and filtered in the processing process, and therefore the content of fluff and dust in the air is reduced.

Owner:湖州欣源环保科技有限公司

A movable automatic winding reel

The invention discloses a movable automatic winding reel, which comprises a shell, two take-up reels, a roller, a drive assembly, a bracket assembly, and a power conversion device. A roller is arranged in the middle of the two take-up reels, and There is a bracket assembly, one side of the bracket assembly is equipped with a manual crank, the inside of the drum is equipped with a drive assembly and a power conversion device, the end is equipped with a shell, the middle of the outer shell is equipped with a horizontal steel pipe, and the inside is equipped with a power supply. The starting device, the bracket assembly includes a frame, connecting rods are arranged between the frames, the frame includes a first vertical rod, a second vertical rod, a first horizontal rod, a second horizontal rod are arranged between the first vertical rod and the second vertical rod The bar, the bottom bar, the second cross bar and the bottom bar are provided with arc reinforcements, and the two ends of the bottom bar are provided with movable wheels. The invention can automatically and orderly take up wires, and at the same time has the function of manual wire taking up, and can set different speeds and power according to different diameters of cables, expanding the scope of application. At the same time, the invention has strong portability and can be used in multiple directions. move.

Owner:江苏金兰湾电气科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com