A vertical adjustable take-up reel

A take-up reel, vertical technology, applied in the field of vertical adjustable take-up reel, can solve the problems of copper wire being stretched or even broken, unable to coil the cable, low tensile performance, etc. Stretching or even being pulled off, better wire take-up effect, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

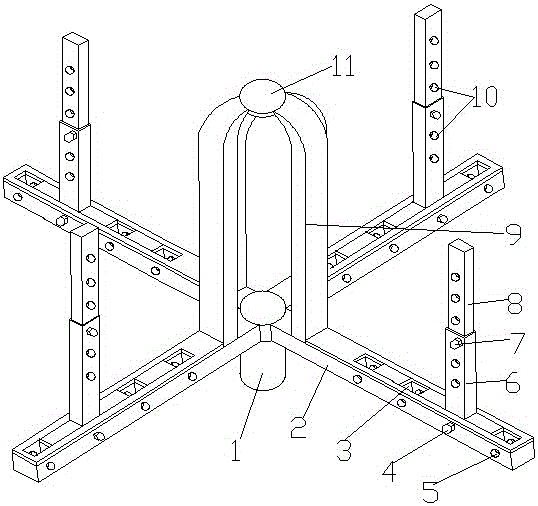

[0018] Such as figure 1 As shown, a vertical adjustable take-up reel includes a rotating shaft 1 and a take-up chassis 2, and the take-up chassis 2 has 3-6 pieces, which are horizontally fixed on the top of the rotating shaft 1 at equal intervals. The line chassis 2 includes a limit roller and a take-up roller 9, the limit roller includes a roller sleeve 6 and a roller bar 8, the roller cover 6 is covered with the roller bar 8, and the roller cover 6 and the roller bar 8 The same side is provided with several second threaded holes 10 at equal intervals, and the second screw 7 passes through the second threaded holes 10 on the same side of the roller sleeve 6 and the roller bar 8 and is fixed by a nut; A take-up roller 9 is vertically fixed on the upper end surface of the take-up chassis 2 close to the rotating shaft 1, and several grooves 3 are equally spaced on the upper end surface of the side of the take-up chassis 2 facing away from the rotating shaft 1, A roller sleeve ...

Embodiment 2

[0022] The same as embodiment 1, the difference is that there are three wire receiving chassis 2, which can realize the completion of the basic wire receiving operation, and save steel materials, thereby reducing the cost.

Embodiment 3

[0024] The same as embodiment 1, the difference is that there are five wire-receiving chassis 2, which can ensure a more stable wire-receiving process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com