A corrugated cardboard, composite corrugated cardboard and composite corrugated box

A technology of corrugated cardboard and corrugated paper, which is applied in the field of composite corrugated cardboard, composite corrugated box and corrugated cardboard, and can solve the problems of wasting resources in anti-seismic performance and reducing the space of packaging products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

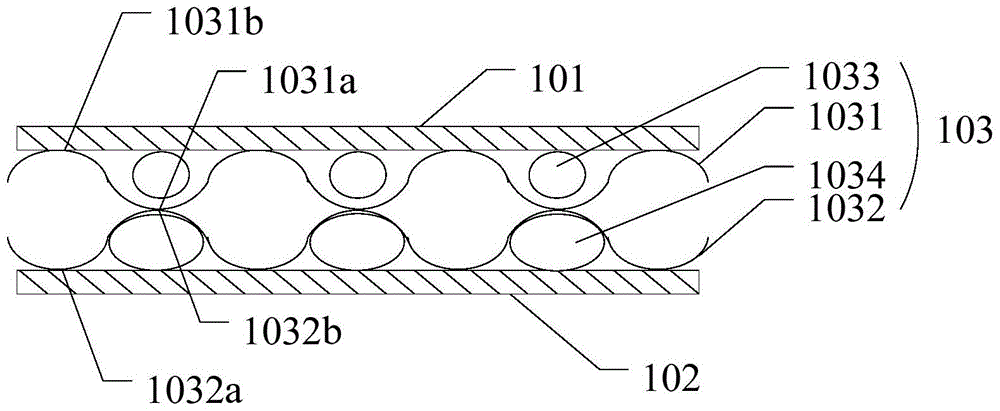

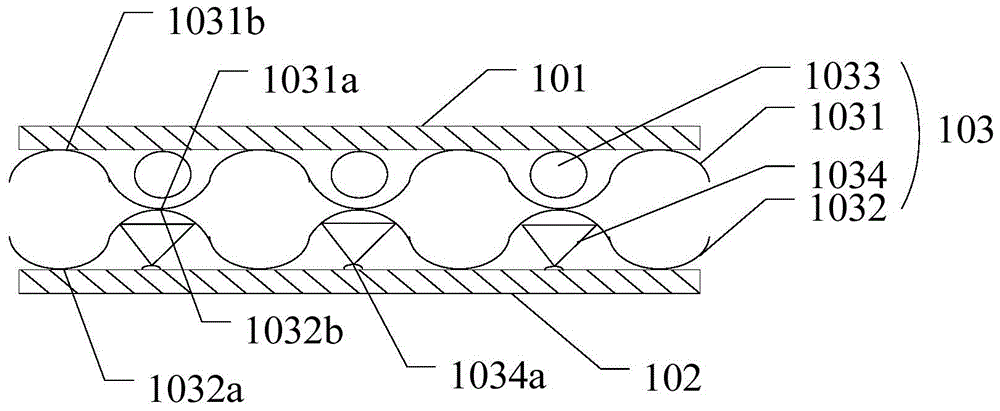

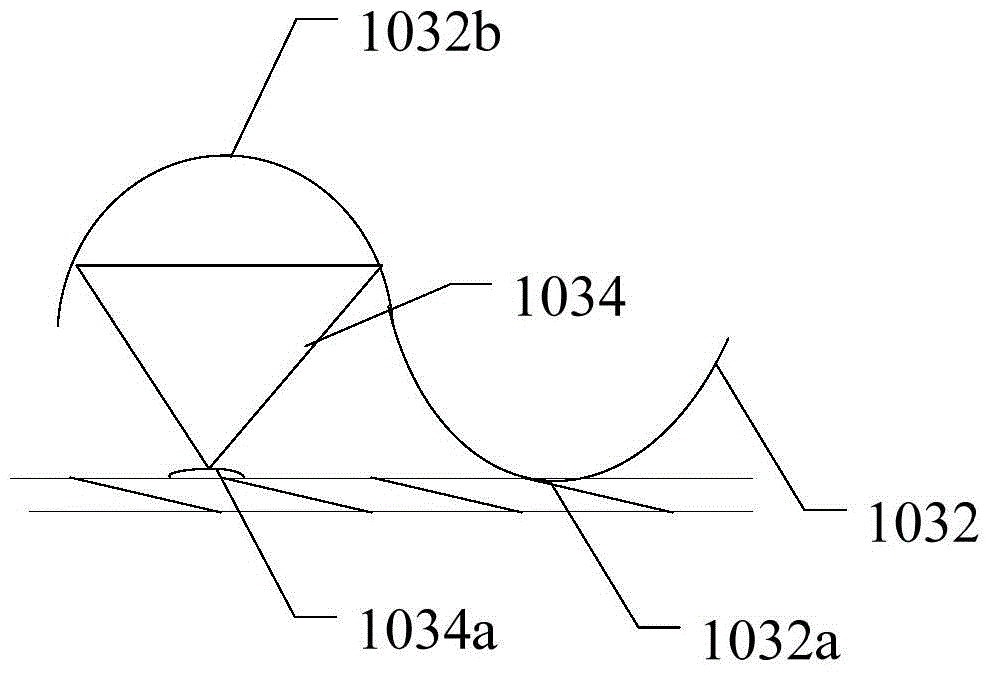

[0048] Such as figure 1 As shown, take the first hollow corrugated paper core 1033 as an example of a hollow circular corrugated paper core, and take the second hollow corrugated paper core 1034 as an example of a hollow oval corrugated paper core. The corrugated paper core can be made of single-layer corrugated paper glued together. The circular corrugated paper core or the elliptical corrugated paper core has elasticity and can resist external impact to form a highly elastic corrugated paper board. In addition, in another embodiment, such as Figure 2-a shown and Figure 2-b as shown, Figure 2-b for Figure 2-a Take the second hollow corrugated paper core 1034 as a hollow inverted triangular corrugated paper core as an example, wherein the inverted triangular corrugated paper core can be made by bonding a single layer of corrugated paper, and the single layer of corrugated paper is folded into a triangle and bonded to obtain a hollow inverted triangle The corrugated pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com