Sealed Insulated Tank

A technology of thermal insulation and sealing layer, applied in the field of tank storage and/or tank wall structure, which can solve the problem of weak thermal insulation material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

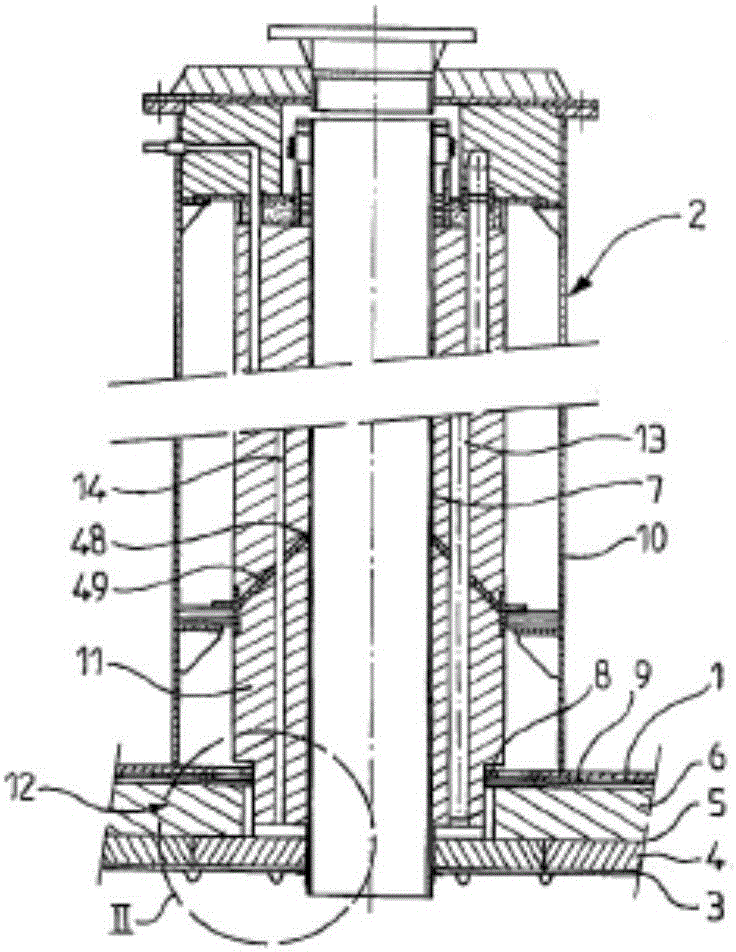

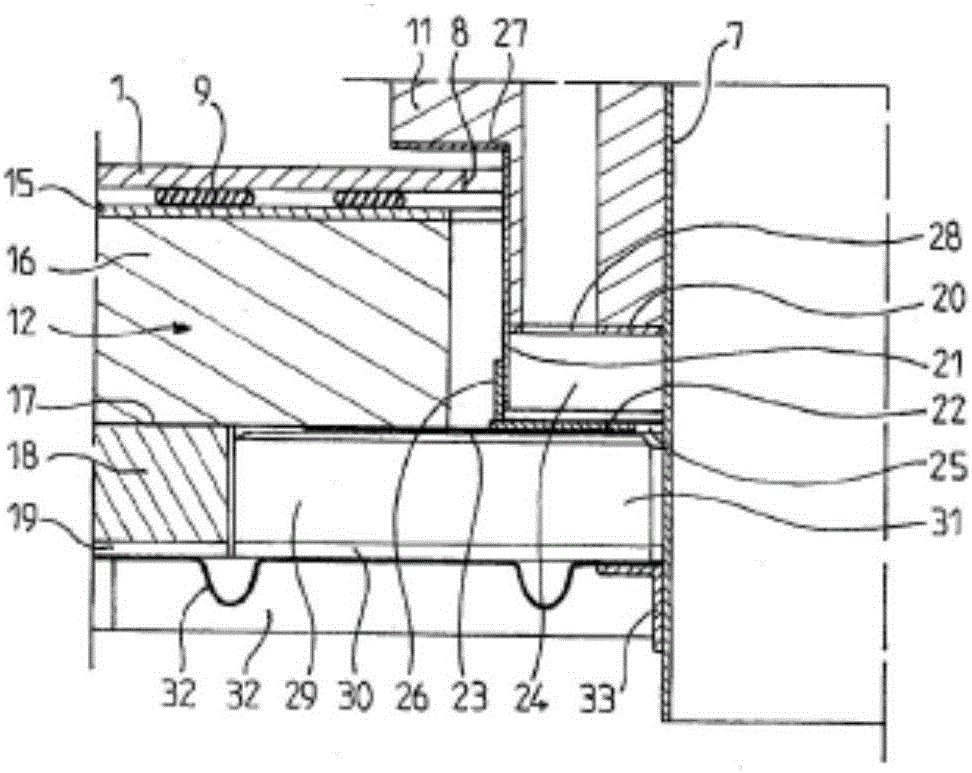

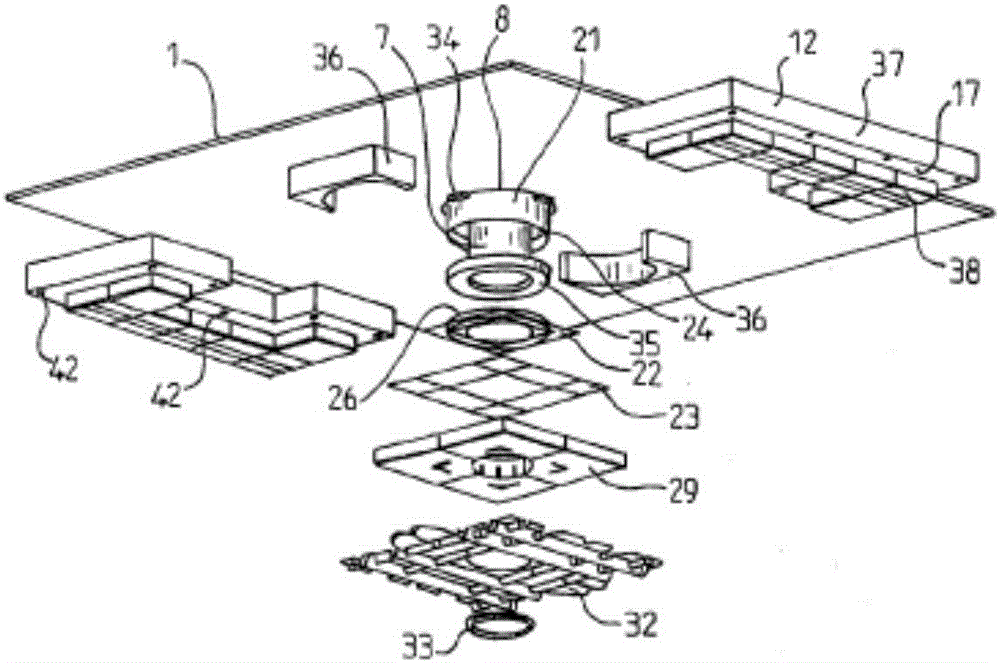

[0059] A hermetically insulated tank consists of tank walls secured to corresponding wall interior surfaces of a support structure. The supporting structure is, for example, the inner hull of a double-hulled hull or a building on land. For the storage of refrigerated liquids, such as LNG, the tank wall comprises at least one sealing barrier and at least one insulating barrier for safety, possibly including a secondary sealing barrier between the support structure and said sealing barrier, in this case referred to as the primary stage Seal the barrier, between.

[0060] The tank can be manufactured in different shapes, eg prismatic inside the hull of a boat, or cylindrical on land, and so on. By convention, "on top" means located close to the inside of the tank, and "below" means located close to the support structure 1 , regardless of the position of the tank wall relative to gravity.

[0061] figure 1 A liquid collection device 2 is shown passing through the top of a tank....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com