Outdoor fire hydrant with split flange

A fire hydrant and split-type technology, which is applied in fire rescue and other directions, can solve the problems of fire pipe network water volume and pressure drop, fire extinguishing equipment can not effectively extinguish fire, fire hydrant breakage, etc., to save manpower, simple installation, and reduce work intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

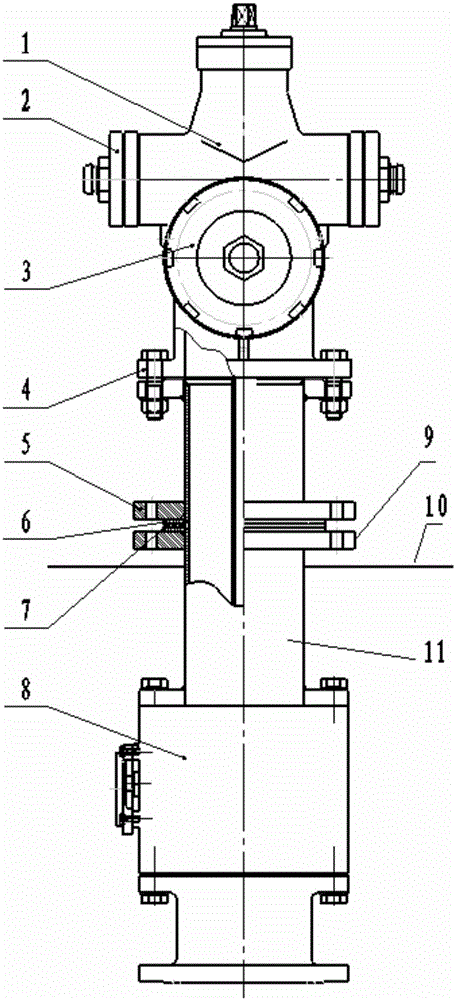

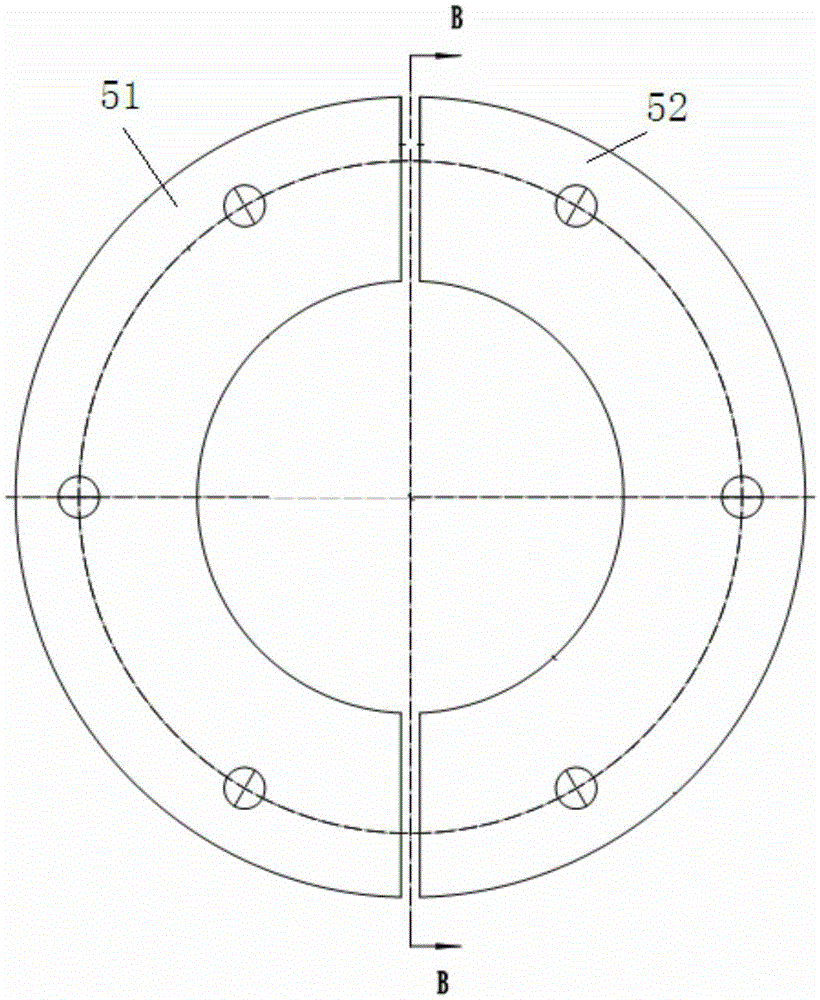

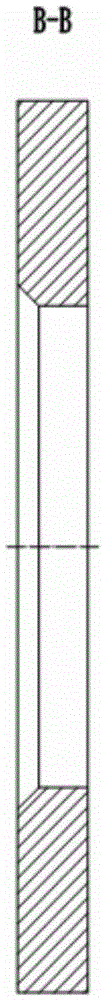

[0019] Such as Figure 1 to Figure 5 As shown, an outdoor fire hydrant with a split flange includes a bolt shell 1 and a lower valve body 8, a bolt shell flange 4 is provided at the bottom of the bolt shell, and a connecting pipe at the bottom of the bolt shell flange 4 is provided with There is an anti-collision flange 5, the upper part of the lower valve body 8 is connected to the lower end of the connecting pipe 11, the upper end of the connecting pipe 11 is connected to the second flange 9, the anti-collision flange 5 is connected to the second flange 9, and the second flange 9 is located at the position where the fire hydrant is installed close to the upper part of the ground 10. The anti-collision flange 5 includes two thin semi-cylindrical ring structures 51, 52 with axial holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com