Bus bridge structure and bus bridge system

A bus bridge and busbar technology, which is applied in busbar/circuit layout, cooling busbar device, fully enclosed busbar device, etc., can solve the problems of deep front and rear extension of commutation copper bars, affecting the normal opening of compartment pressure relief plates, etc. Normal pressure relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

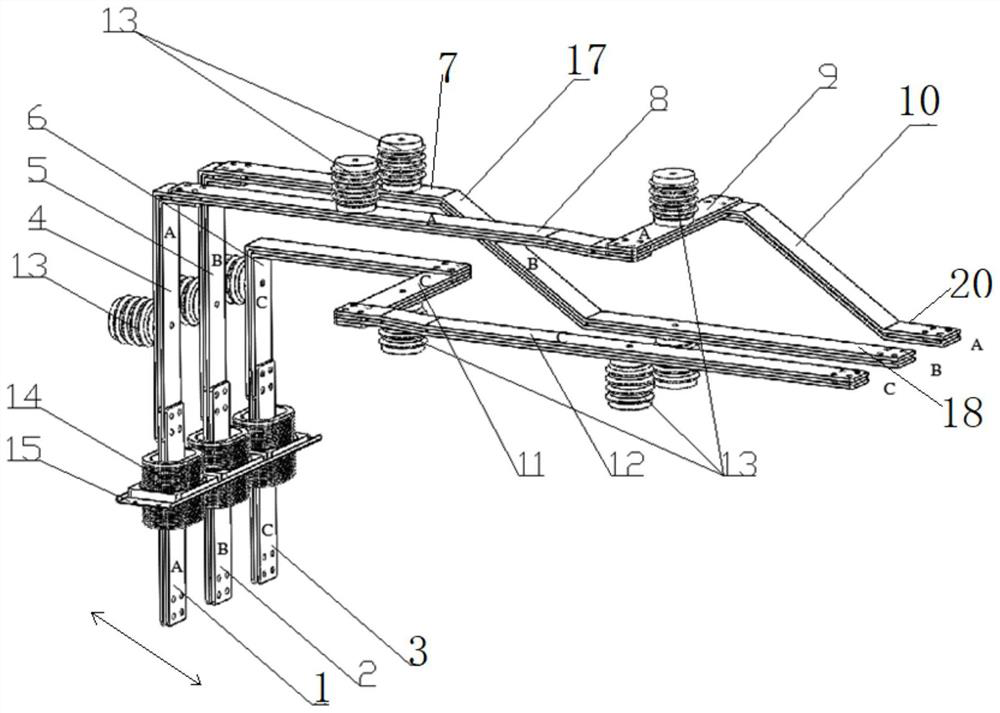

[0042] This embodiment provides a bus bridge structure, such as Figure 1 to Figure 4 As shown, it includes a vertical bridge body and a horizontal bridge body.

[0043] Among them, the vertical bridge body includes A-phase lead-out bar 1, B-phase lead-out bar 2, C-phase lead-out bar 3, and A-phase lead-out bar 1 connected to phase A Corner row 4, B-phase corner row 5 connected to B-phase lead-out row 2, C-phase corner row 6 connected to C-phase lead-out row 3. A-phase lead-out bar 1, B-phase lead-out bar 2, and C-phase lead-out bar 3 are drawn from the inside of the switchgear and extend vertically upward. The A-phase corner row 4, the B-phase corner row 5 and the C-phase corner row 6 all extend vertically upwards and bend horizontally toward the first direction at their respective tops to form a horizontal bending portion; the A-phase corner row 4 and the B-phase corner row The bottoms of the vertical sections of the phase 5 and C-phase corner rows 6 are connected to their c...

Embodiment 2

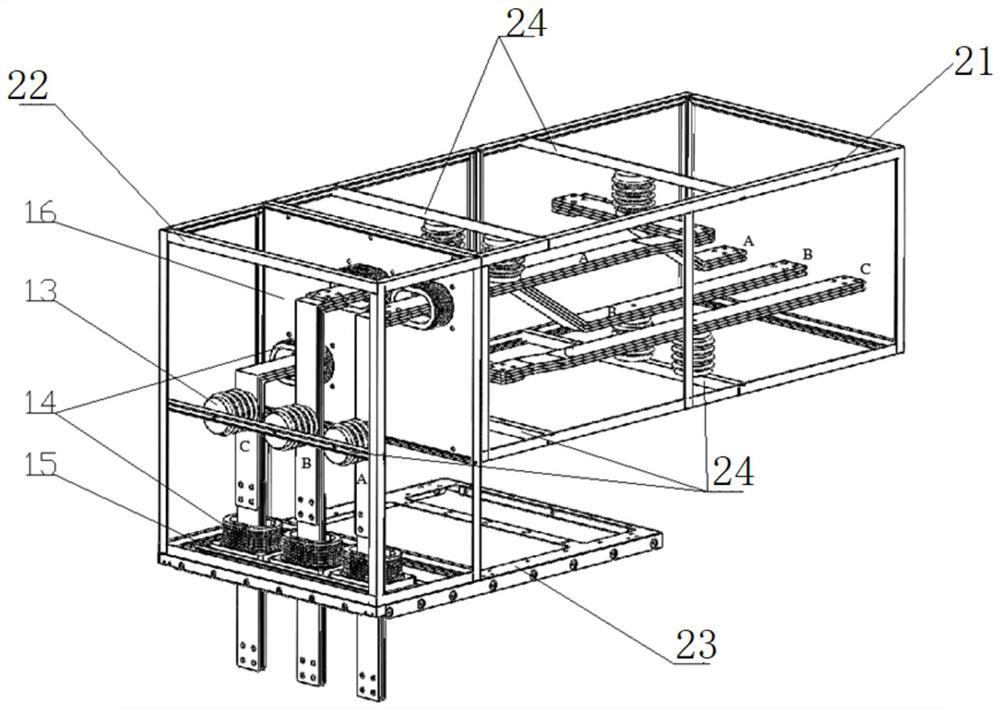

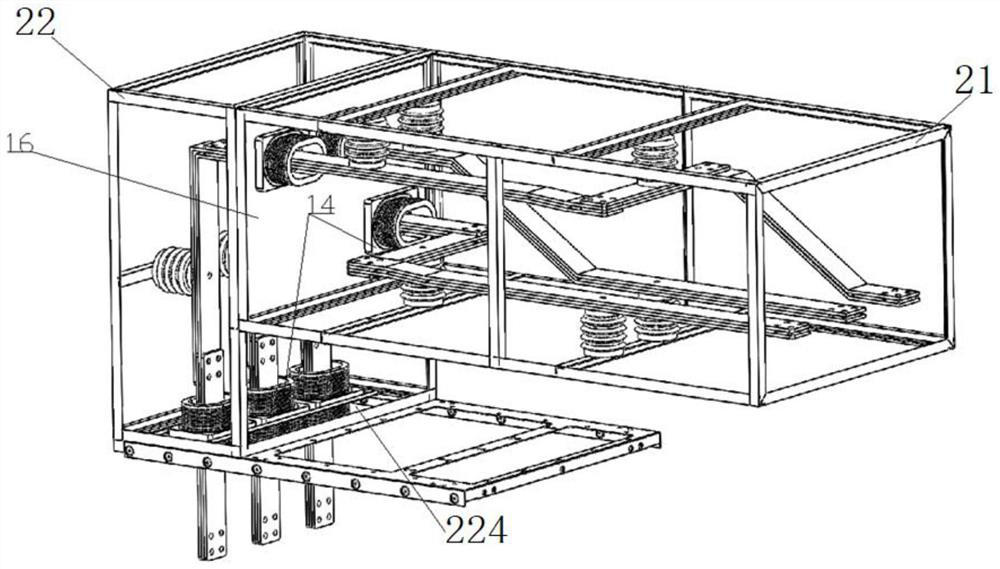

[0065] This embodiment provides a bus bridge system, which includes the bus bridge structure in Embodiment 1 and switch cabinets arranged at both ends of the bottom of the bus bridge, and the vertical bus bridge box 22 is arranged on the top cover 23 of the switch cabinet. The busbar bridge structure in the busbar bridge system has a small depth along the front and rear directions of the switchgear, which can ensure the normal pressure relief of adjacent switchgear compartments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com