Testing ring for measuring inner and outer radial contact stress of rubber sleeve

A contact stress and stress testing technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problem of measuring the radial contact stress between the rubber cylinder and the casing without effective means, so as to avoid the expansion and deformation of the pipeline, reduce the pressure, increase the The effect of reliability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

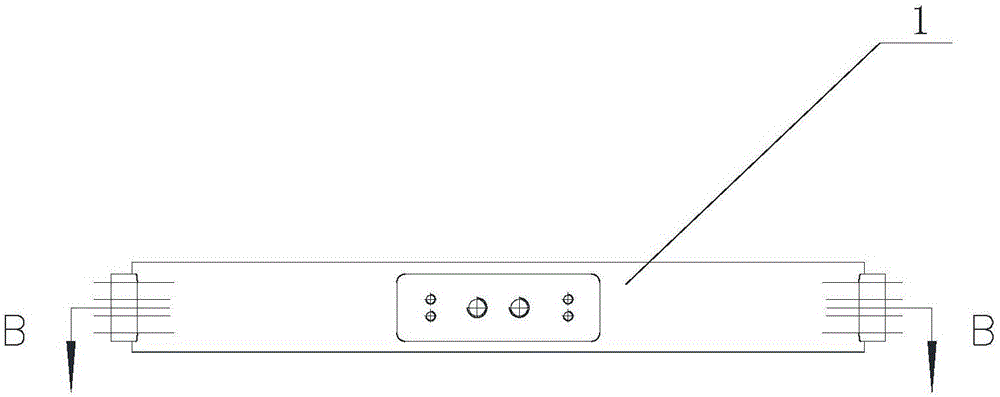

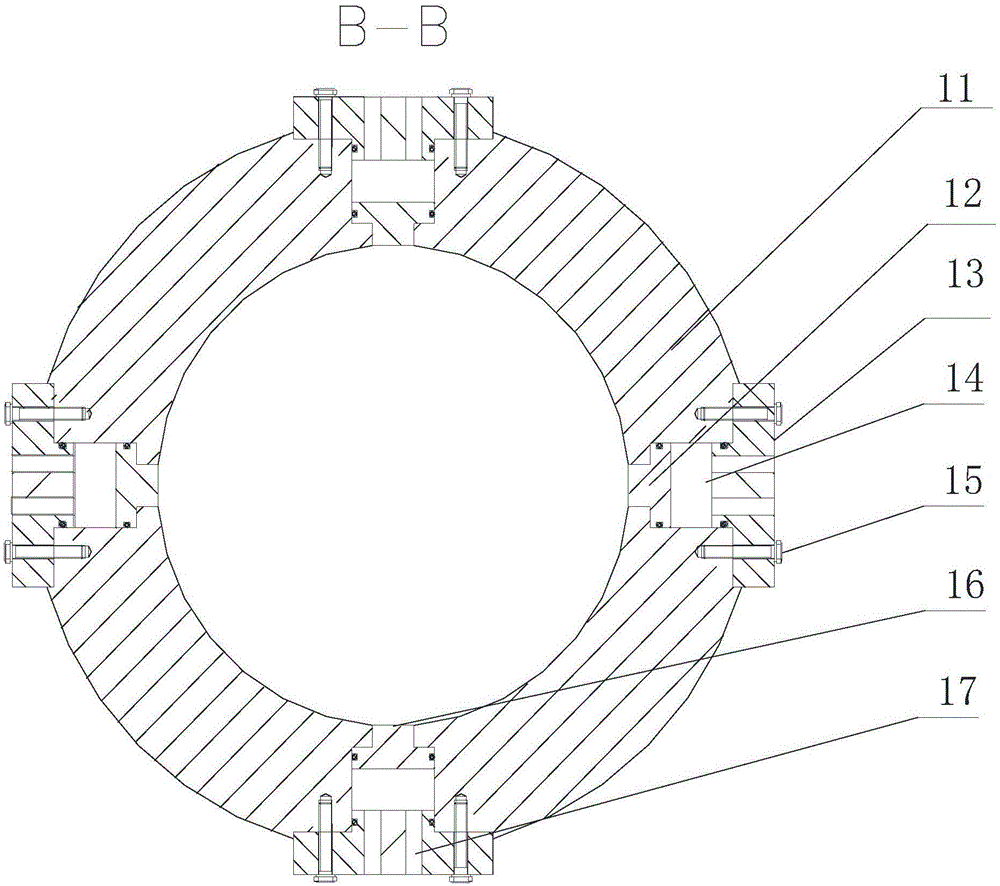

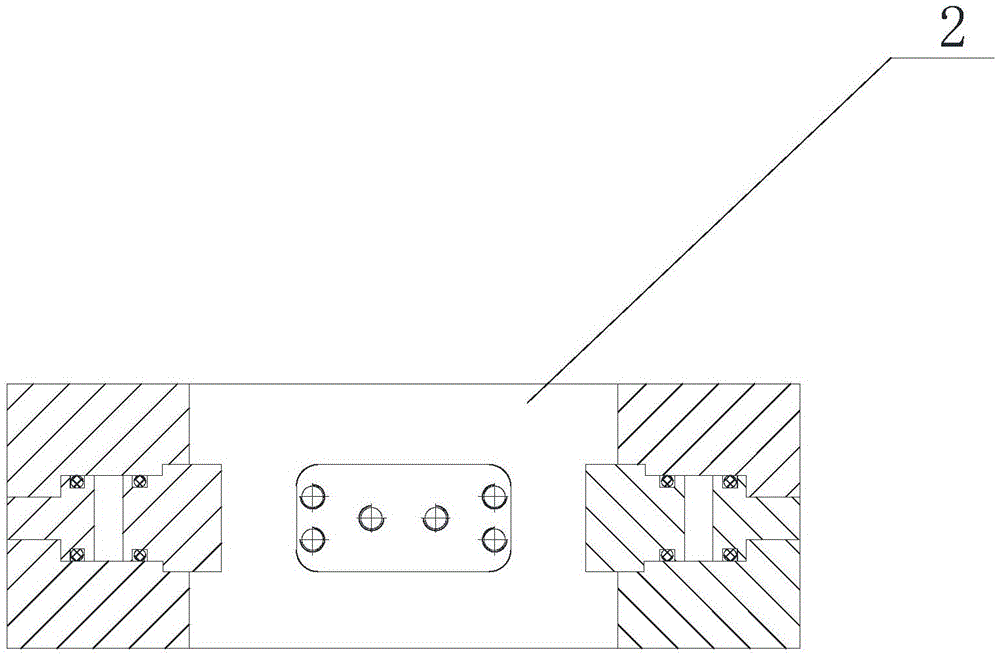

[0022] A test ring capable of measuring the inner and outer radial contact stress of a rubber cylinder, comprising an outer contact stress test ring 1 and an inner contact stress test ring 2 .

[0023] Depend on figure 1 to combine figure 2 As shown: the external contact stress test ring 1, its main body is an annular base 11, on the annular base 11 there are several radially stepped holes along the circumference, and an external pressure transmission piston 12 is inserted inside the radially stepped holes, and the radially stepped The outer side of the hole is fixedly connected with the first plug 13 by bolts 15, and the pressure transmission contact surface 16 of the head of the external pressure transmission piston is on the same curved surface as the inner ring surface of the annular base. The above-mentioned external pressure transmission piston 12 and the first plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com