Flexural fatigue inspection machine of air spring

An air spring and bending fatigue technology, which is applied in the field of air spring bending fatigue testing machine, can solve problems such as inspection, and achieve the effects of convenient use, bending fatigue inspection and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

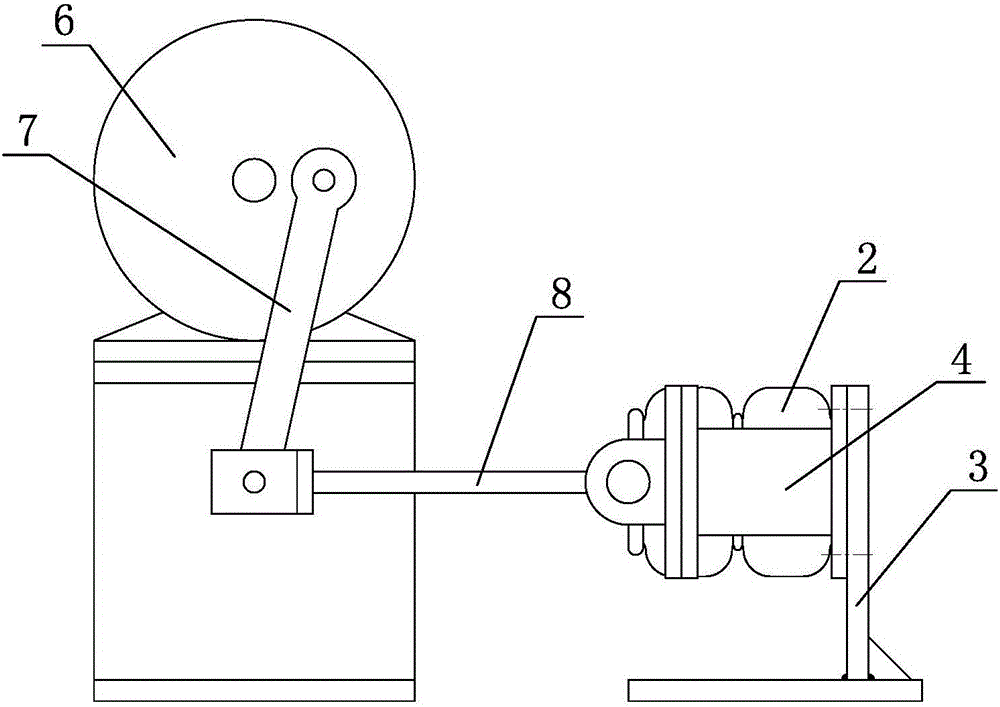

[0021] Embodiment 1: As shown in the figure, an air spring bending fatigue inspection machine includes a rotating shaft 1 and a frame 3 for fixing the air spring 2. The frame 3 is fixedly provided with two axially parallel to the air spring 2. The connecting rod 4, the two connecting rods 4 are located on both sides of the air spring 2 respectively, the rotating shaft 1 is connected to the connecting rod 4, the rotating shaft 1 is fixedly connected with the center point O of the end of the air spring 2 and is connected with the axial direction of the air spring 2. Perpendicular to each other, the contact part of the rotating shaft 1 with the air spring 2 is flat, and the rotating shaft 1 is connected with a rotating shaft swing drive mechanism to drive the air spring 2 to bend. The rotating shaft swing drive mechanism includes a drive motor 5, a turntable 6, a rocker 7 and The swing rod 8, the turntable 6 and the drive shaft of the drive motor 5 are coaxially and fixedly connec...

Embodiment 2

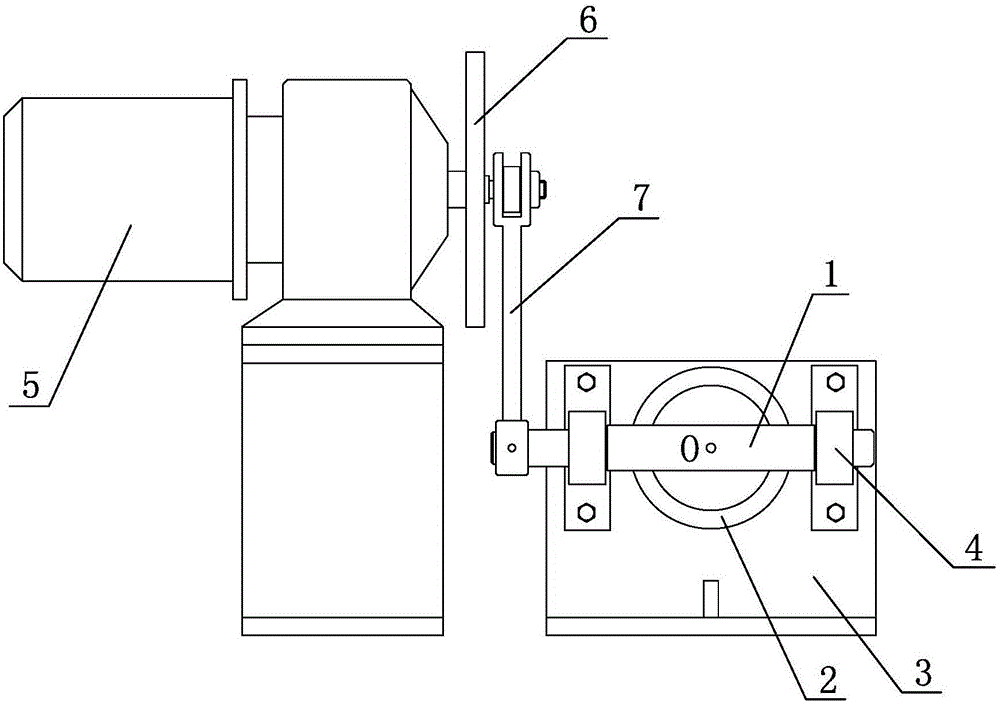

[0022] Embodiment 2: As shown in the figure, an air spring bending fatigue inspection machine includes a rotating shaft 1 and a frame 3 for fixing the air spring 2. The frame 3 is fixedly provided with two axially parallel to the air spring 2. The connecting rod 4, the two connecting rods 4 are located on both sides of the air spring 2 respectively, the rotating shaft 1 is connected to the connecting rod 4, the rotating shaft 1 is fixedly connected with the center point O of the end of the air spring 2 and is connected with the axial direction of the air spring 2. Perpendicular to each other, the contact part of the rotating shaft 1 with the air spring 2 is flat, and the rotating shaft 1 is connected with a rotating shaft swing drive mechanism to drive the air spring 2 to bend. The rotating shaft swing drive mechanism includes a drive motor 5, a turntable 6, a rocker 7 and The rocker 8, the turntable 6 and the drive shaft of the drive motor 5 are coaxially and fixedly connected...

Embodiment 3

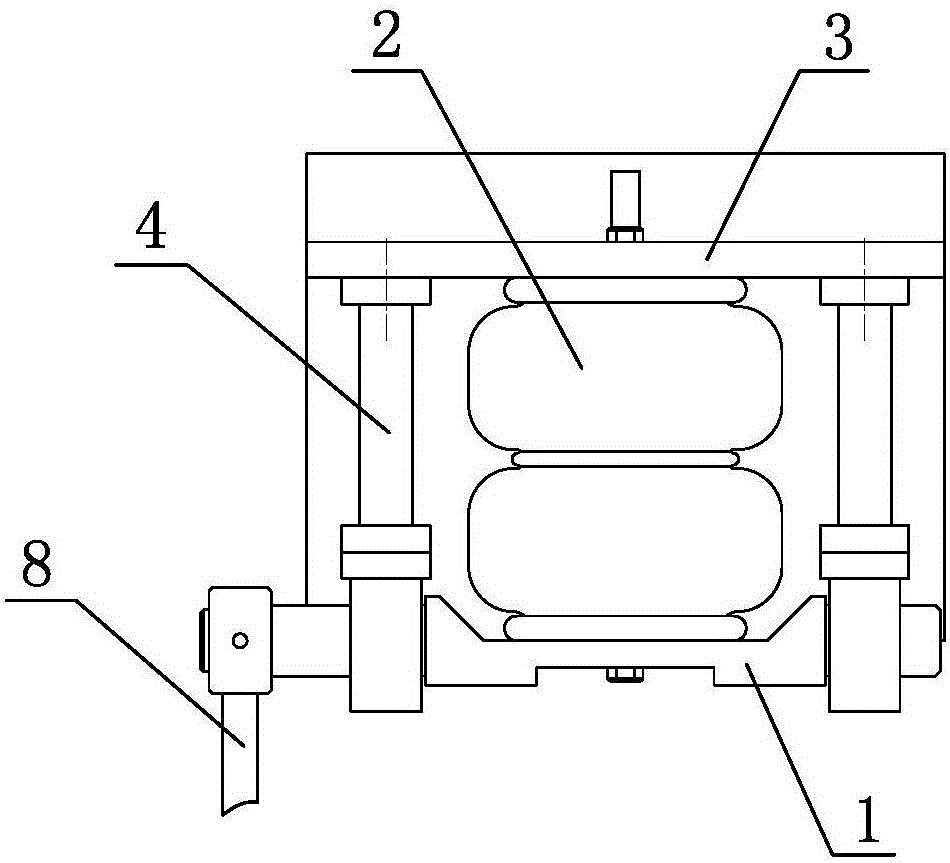

[0023] Embodiment 3: As shown in the figure, an air spring bending fatigue inspection machine includes a rotating shaft 1 and a frame 3, and two connecting rods 4 parallel to the axial direction of the air spring 2 are fixed on the frame 3, and the two are connected. The rods 4 are respectively located on both sides of the air spring 2, the rotating shaft 1 is connected to the connecting rod 4, the rotating shaft 1 is fixedly connected with the center point O of the end of the air spring 2 and is perpendicular to the axial direction of the air spring 2, and the rotating shaft 1 is connected to the center point O of the end of the air spring 2. The contact part of the air spring 2 is flat, the frame 3 is screwed with an adjusting screw 9, the adjusting screw 9 is parallel to the connecting rod 4, and the end of the adjusting screw 9 is integrally provided with an adjusting plate 91 for fixing and installing the air spring 2, The adjusting screw 9 is fixed with the frame 3 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com