Wire clamp

A wire clip and wire technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of weak shear strength, damage to the core material, and inability to exert clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] [Best plan for implementing the invention]

[0027] Embodiments of the present invention will be described below with reference to the drawings.

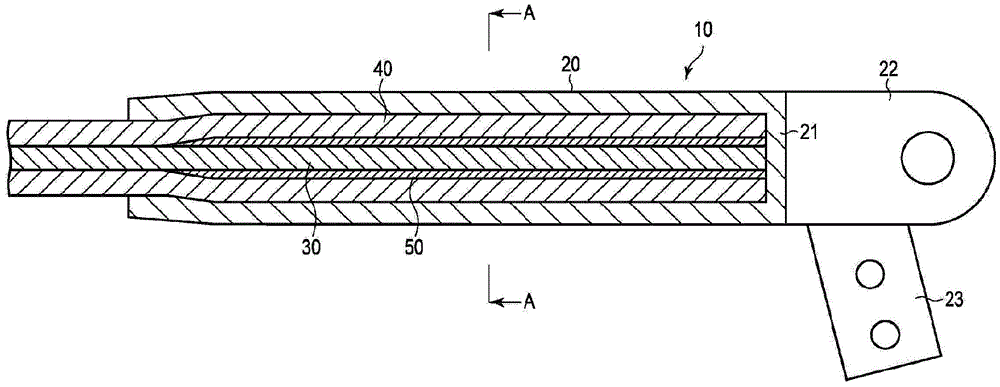

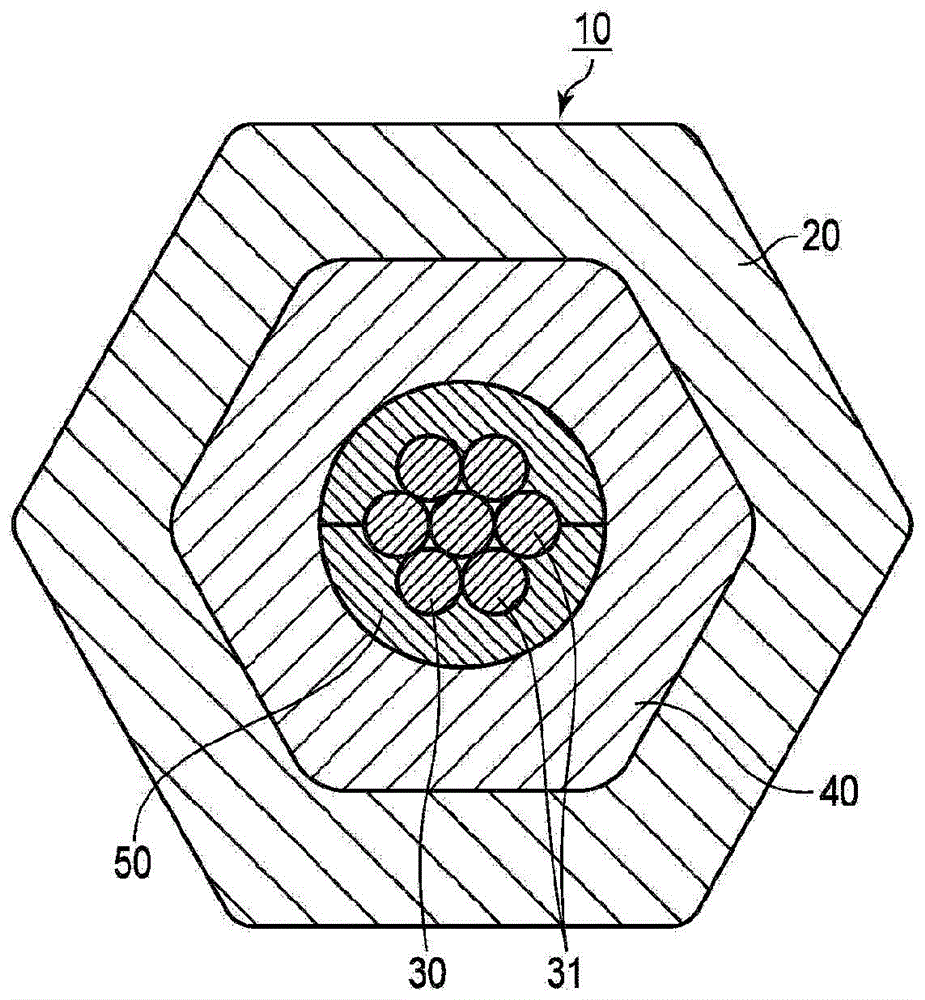

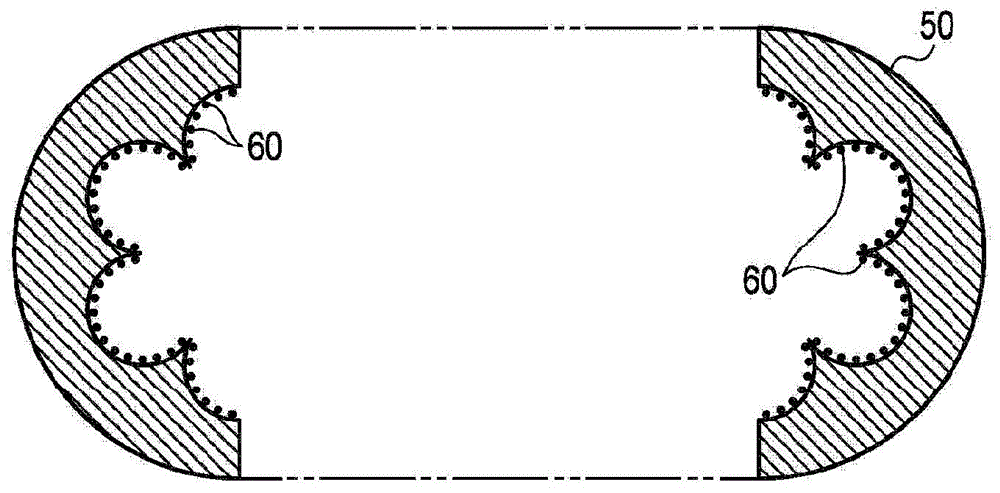

[0028] figure 1 is a longitudinal sectional view showing the integrated electric wire clamp 10 according to the first embodiment of the present invention, figure 2 is along figure 1 The A-A line cuts off the wire clamp and looks at the cross-sectional view from the direction of the arrow, image 3 is a cross-sectional view showing the metal cushioning material 50 assembled in the wire clamp 10, Figure 4 It is a perspective view showing the metal cushioning material 50 and the carbon fiber core material 30 assembled in the wire clamp 10 . In the description, the axial direction refers to the extending direction of the base wire 31 , which is the same direction as the pulling force generated on the base wire 31 . The electric wire clamp is a member for fixing the end of the electric wire, and it is necessary to have a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com