Crossbeam clamping mechanism used for heavy-duty crossbeam-elevating gantry machine tool

A technology of gantry machine tools and clamping mechanisms, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the inconvenience of maintenance of the sliding guide rail surface of the beam and the column guide rail, affect the repeated positioning accuracy of the machine tool, and not adapt Problems such as beam clamping requirements, to achieve stable and reliable detachable fixed connection, convenient and fast installation process, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

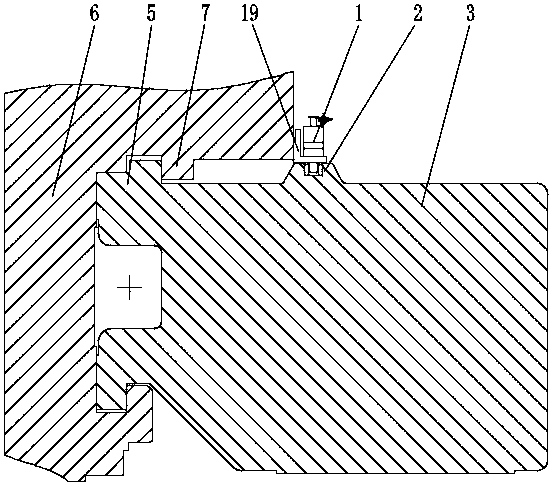

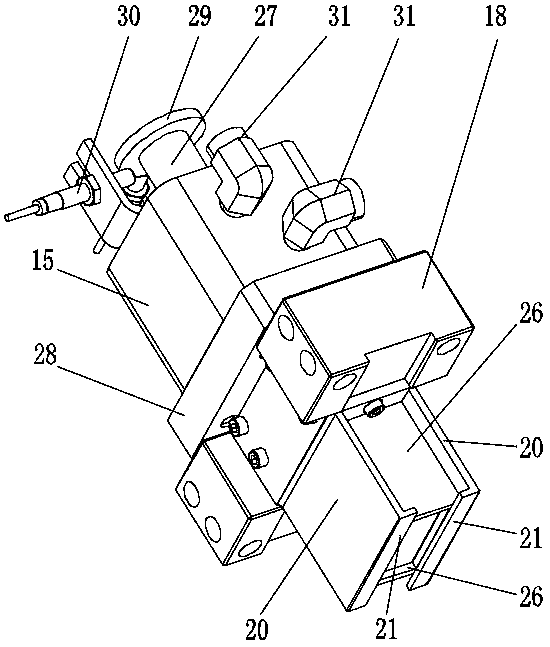

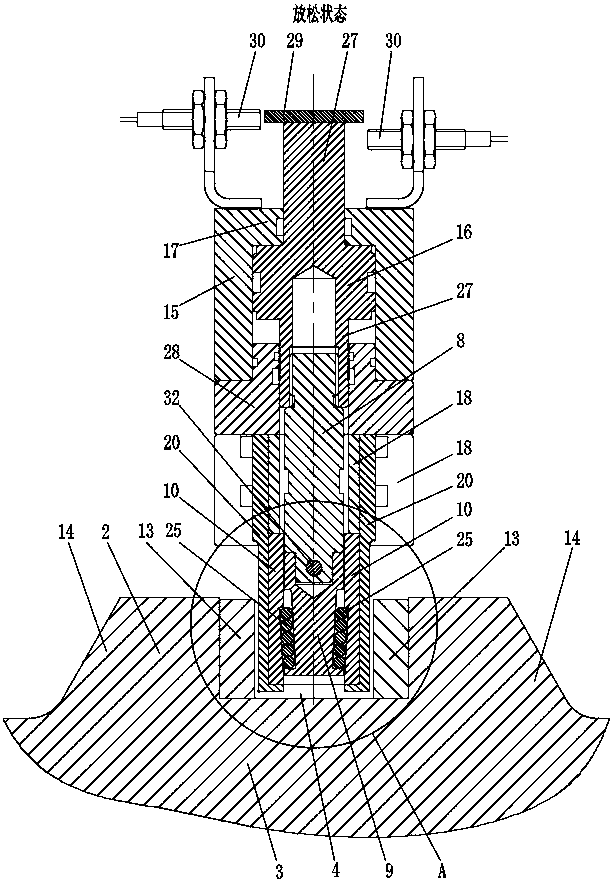

[0032] Such as Figures 1 to 6 As shown, a beam clamping mechanism for a heavy-duty beam lifting gantry machine tool includes a clamping part 1 and a clamping guide rail part 2, the clamping guide rail part 2 is fixedly arranged on a machine column 3, and the clamping guide rail part 2 has a clamping Tighten the guide rail groove 4, the clamping guide rail groove 4 is parallel to the machine tool column guide rail 5, specifically, both sides of the clamping guide rail groove 4 are parallel to the machine tool column guide rail 5, and the clamping part 1 is fixedly connected to the machine tool beam 6;

[0033] The clamping part 1 includes a driving structure, the driving structure is connected with a driving rod 8, and can control the driving rod 8 to move axially, the front end of the driving rod 8 is connected with a wedge-shaped pressing block 9, and the rear end of the wedge-shaped pressing block 9 has a mounting hole , the front end of the driving rod 8 is inserted into t...

Embodiment 2

[0041] On the basis of Embodiment 1, the clamping guide rail part 2 is detachably fixed on the machine tool column 3, so that when the clamping guide rail part 2 is worn or damaged due to long-term use, the clamping can be further conveniently and quickly realized. Replacement or removal of the tight guide rail part 2 for maintenance.

Embodiment 3

[0043] Such as figure 1 , 3 , 4, 5, and 6, on the basis of Embodiment 1, the clamping rail part 2 and the machine column 3 are specifically integrally formed, and the left and right sides of the clamping rail part 2 have diagonal braces 14, and the diagonal braces 14 extends along with the length of the clamping guide rail groove 4, which is more conducive to ensuring the connection strength between the clamping guide rail part 2 and the machine column 3, and the diagonal brace part 14 improves the support strength of the machine tool column 3 to the clamping guide rail part 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com