A differential planetary reducer for a crane

A planetary reducer, crane technology, applied in the direction of differential transmission, mechanical equipment, transmission, etc., can solve the problems of reliability and safety to be improved, inability to flexibly select the output speed, etc., to save operation time and space utilization. High rate, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

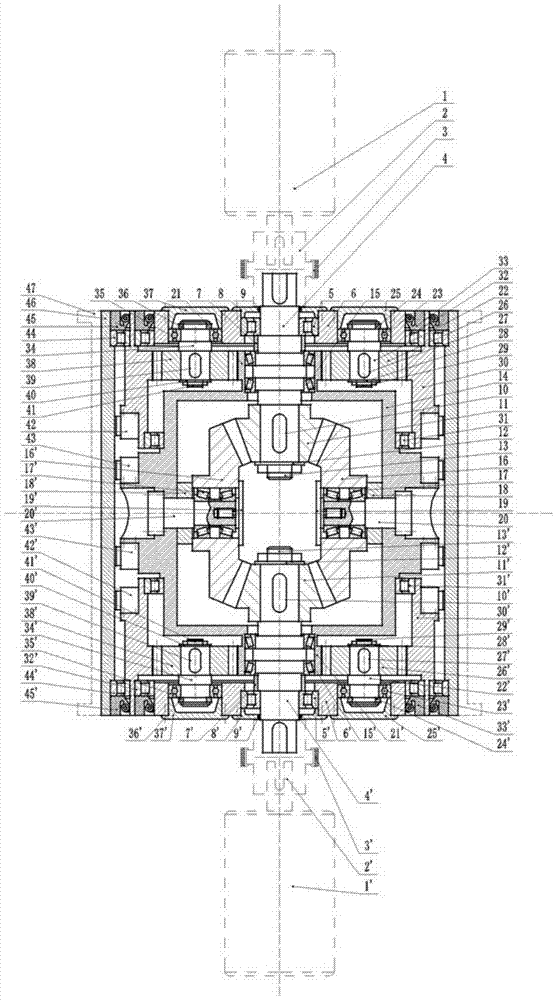

[0029] Such as figure 1 As shown, it is an embodiment of a differential planetary reducer for a crane in the present invention, the pair of input shafts 4, 4' connected to the two motors 1, 1' through couplings 2, 2' respectively, The cylindrical roller bearings 5, 5' are supported in the frame 6, 6', and the inner rings of the two sets of symmetrically distributed cylindrical roller bearings 5, 5' are axially positioned with the sleeves 7, 7'. 5. The outer ring of 5' is pressed by bearing cover 8, 8' and sealed with sealing ring 9, 9'; two sun gear bevel gears 11, 11' are respectively keyed to the output ends of two input shafts 4, 4' , and on the inner sides of the two sun gear bevel gears 11, 11', there are retaining rings 12, 12' and two shaft end nuts 13, 13' to compress them;

[0030] The two ends of the cylindrical output planet carrier 14 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com