Drainage asphalt mixture water permeability performance test device and test method thereof

A technology for water permeability and drainage of asphalt, used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

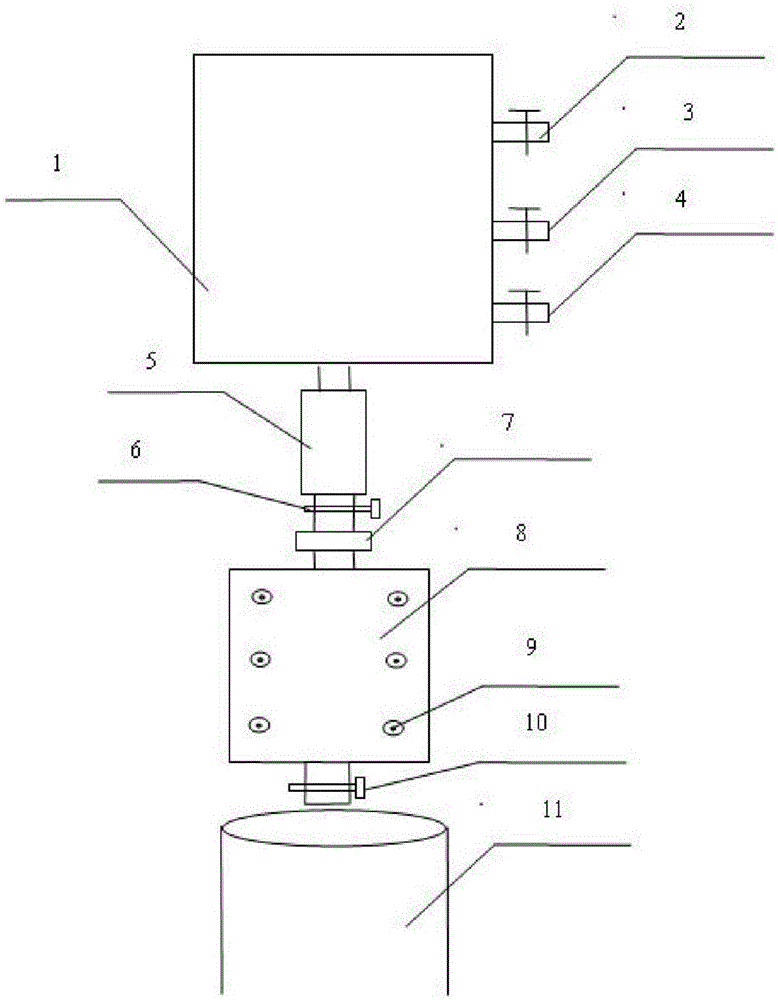

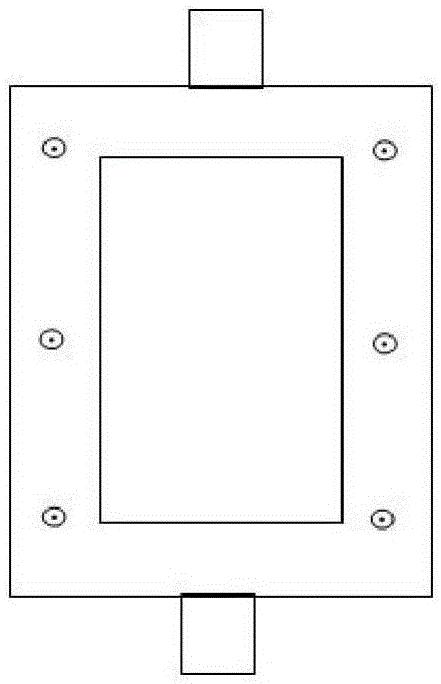

[0028] Such as figure 1 As shown, a drainage asphalt mixture water permeability testing device, including a water storage tank 1, a tubular monitor 5 made of transparent material, a test mold 8 for fixing a test piece, a water volume collector 11, the water storage tank 1. The outlet pipe at the bottom is connected to the upper end of the monitor 5, and the lower end of the monitor 5 is connected to the inlet pipe at the upper end of the test mold 8 through a pipe and a connecting nut 7. The monitor 5 is transparent and can be used to observe whether there are air bubbles in the water during the test The water volume collector 11 is located directly below the outlet pipe at the lower end of the test mold 8, the first valve 6 is installed on the pipeline between the monitor 5 and the test mold 8, and the outlet pipe at the lower end of the test mold 8 A second valve 10 is installed on it.

[0029] In this embodiment, the circumferential wall of the water storage cylinder 1 is ...

Embodiment 2

[0034] A method for testing the water permeability of drainage asphalt mixture utilizing the device, comprising the following steps:

[0035] (1) Formed test piece: OGFC-13 type asphalt mixture is used, and the mineral material gradation composition designed by its mix ratio is shown in Table 1. According to the designed asphalt mixture mix ratio, the rutting test plate of the drainage asphalt mixture is formed indoors. Cut the rutting test plate into 200mm×50mm×50mm test pieces with a cutting machine, measure the size of the test piece, and calculate the cross-sectional area A of the test piece;

[0036] Table 1 Gradation composition of OGFC-13 asphalt mixture

[0037]

[0038] (2) Install the piece to be tested: seal the four side walls of the asphalt mixture test piece with epoxy resin, and the surfaces of 50mm×50mm at both ends are not closed; after the epoxy resin is cured, put the test piece into the test mold 8, and the test piece Place a 2mm-5mm thick rubber sheet ...

Embodiment 3

[0044] A method for testing the water permeability of drainage asphalt mixture utilizing the device, comprising the following steps:

[0045] (1) Formed test piece: OGFC-13 type asphalt mixture is used, and the mineral material gradation composition designed by the mix ratio is shown in Table 3. According to the designed asphalt mixture mix ratio, the rutting test plate of the drainage asphalt mixture is formed indoors. Cut the rutting test plate into 200mm×50mm×50mm test piece by cutting machine, measure the size of the test piece, and calculate the cross-sectional area A of the test piece.

[0046] Table 3 Gradation composition of OGFC-13 asphalt mixture

[0047]

[0048] (2) Install the piece to be tested: seal the four side walls of the asphalt mixture test piece with epoxy resin, and the surfaces of 50mm×50mm at both ends are not closed; after the epoxy resin is cured, put the test piece into the test mold 8, and the test piece Place a 2mm-5mm thick rubber sheet betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com