An anti-tipping, fast-group catenary operation ladder truck

A catenary and anti-overturning technology, which is applied to ladders, buildings, overhead lines, etc., can solve the problems of complex structure, simple structure, and small weight, and achieve the effects of reducing labor intensity, ensuring safe use, and saving the cost of ladder cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

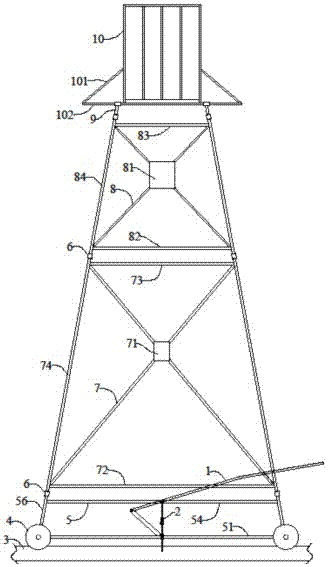

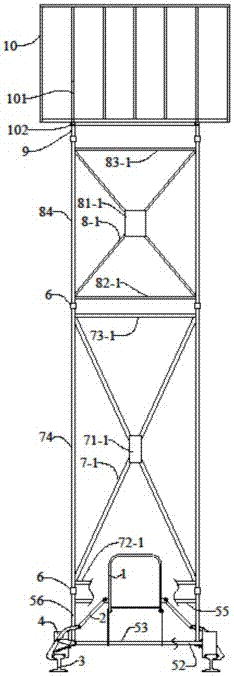

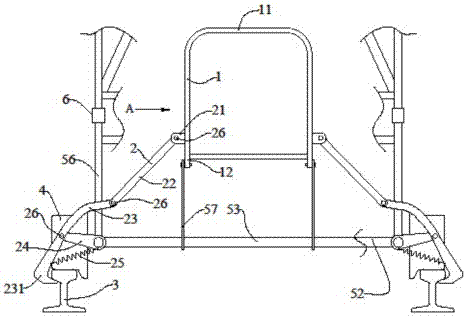

[0037] See attached figure 1 And attached figure 2 , an embodiment of an anti-overturning, fast-group catenary work ladder truck of the present invention, including a base 5, a ladder body and a work platform 10. Wherein, the base 5 is provided with a locking mechanism for preventing the rollover of the ladder car, and the locking mechanism is a push-type normally closed locking linkage mechanism, including a push handrail 1 on the base 5, and each of the two sides of the push handrail 1 A connecting rod locking device 2 is connected. The ladder body is combined and connected by the lower segment 7 and the upper segment 8 , the top of the upper segment 8 is connected with the working platform 10 , and the bottom of the lower segment 7 is connected with the base 5 . The joints between the base 5 and the lower section 7, between the upper and lower secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com