Photocurable aluminum foil anticorrosion coating composition

A technology of anti-corrosion coatings and compositions, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of reducing the curing degree of coatings by adding proportion, environmental friendliness without light curing, poor floating ability of wax powder, etc., to improve the curing effect, The effect of overcoming the problem of oxygen inhibition and improving the density of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

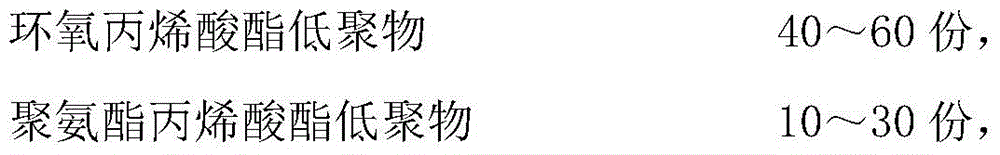

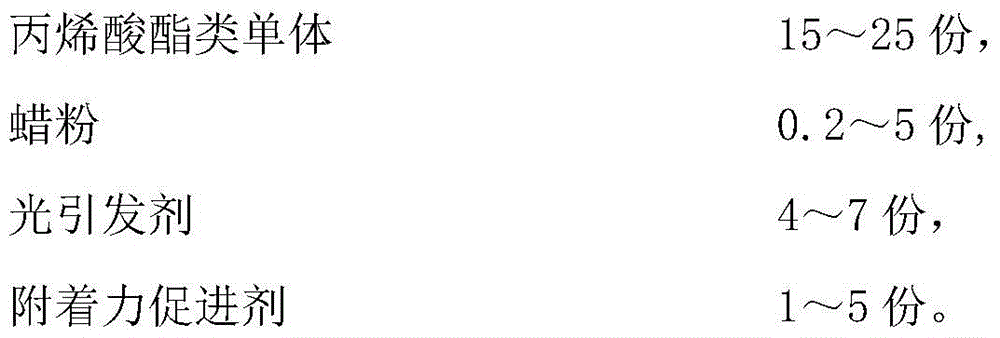

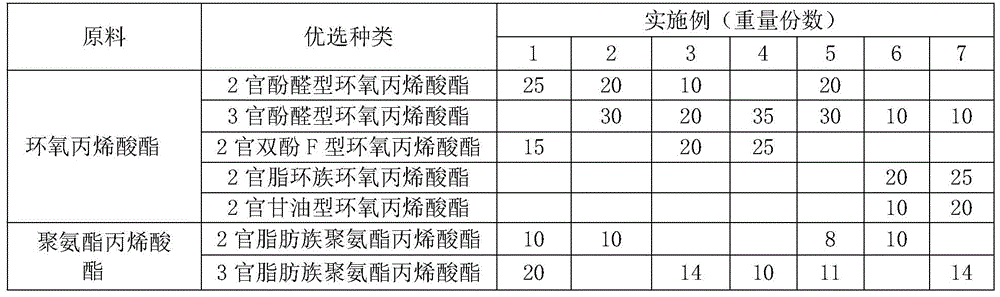

[0023] Examples 1-7 relate to a photocurable anticorrosion coating composition for the surface of aluminum foil, including the components and parts by weight shown in Table 1.

[0024] A 100-micron thick aluminum foil is used as the base material, soaked in 5% sodium hydroxide solution for 30 seconds before use, washed with warm water and dried for later use. Pour the paint into the heating trough, heat it to 70°C, use three-roller gluing, and coat the paint on the surface of the treated aluminum foil, control the film thickness to 2 microns, and directly UV cure after coating, with an energy of 800mJ / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com