Small sliding block type low-speed clutch

A clutch and slider-type technology, applied in the field of clutches, can solve problems such as unsuitable installation, impossibility, and failure of clutches to meet application requirements, and achieve the effect of simple principle and structure, and solving the problems of engagement and disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings.

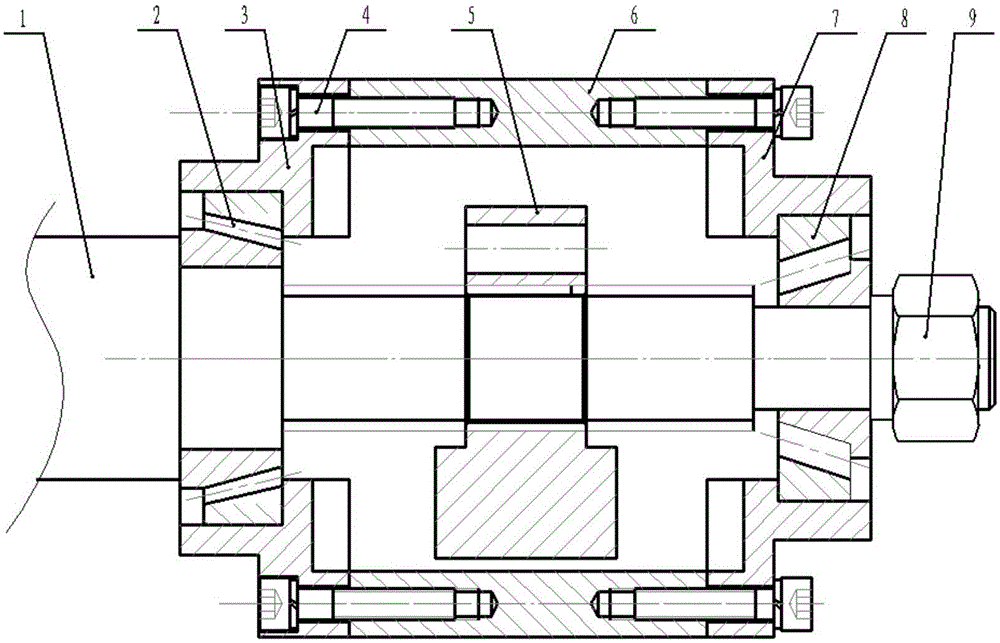

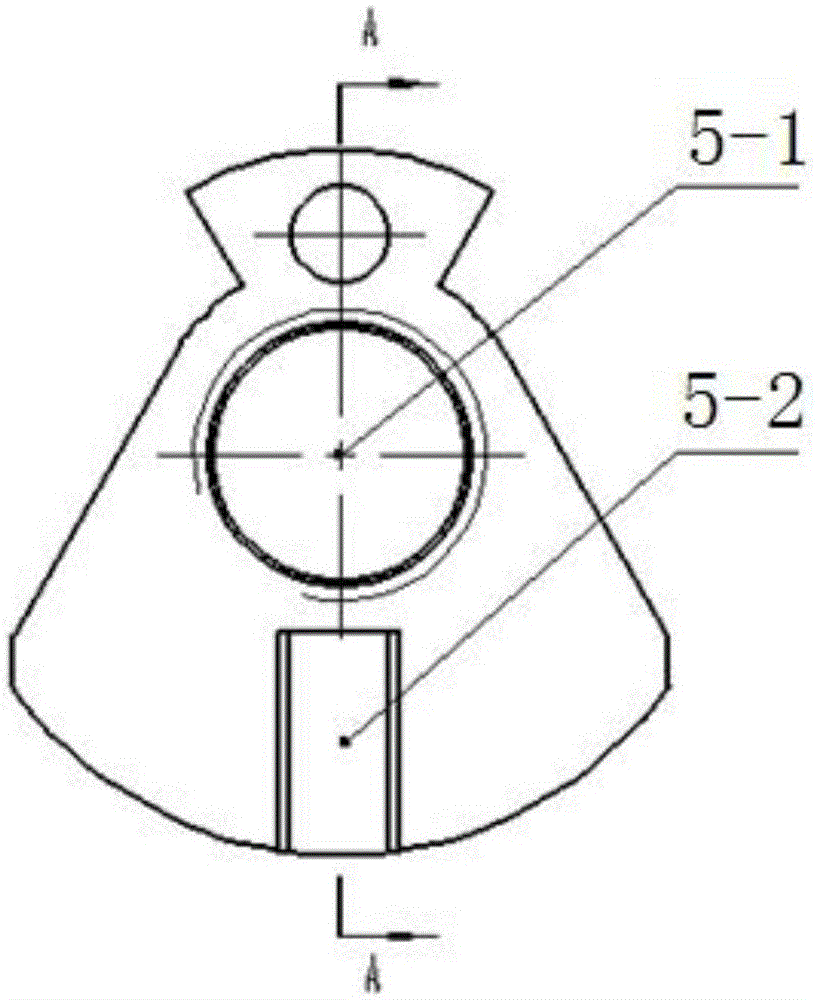

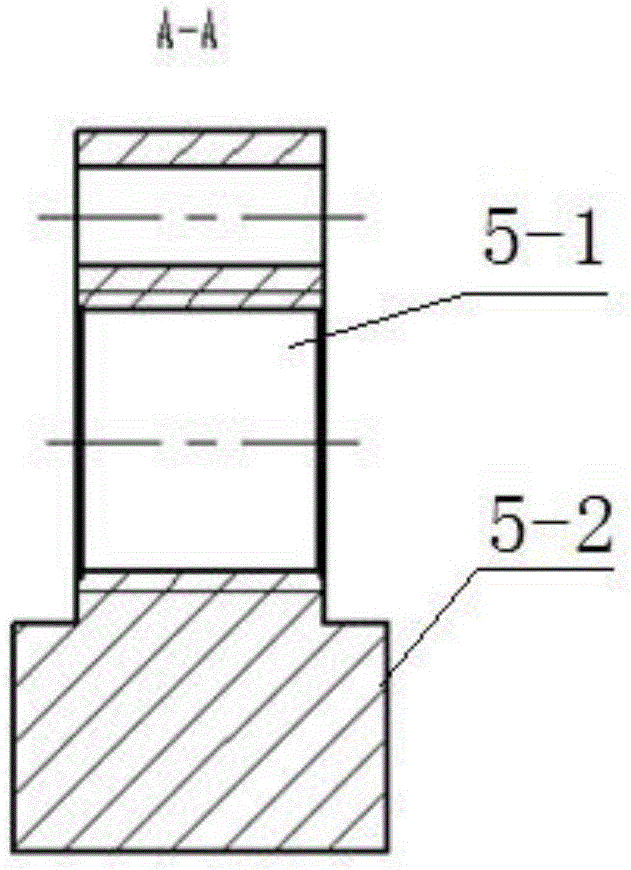

[0019] like Figure 1-7 As shown, the small slider type low-speed clutch of the present invention includes a clutch driving part and a clutch driven part. The active part of the clutch includes a power input shaft 1 and a slider 5, the middle part of the slider 5 is provided with a through hole 5-1, the central axis of the through hole 5-1 deviates from the geometric center of the slider 5, the power input shaft 1 and the through hole 5 -1 is connected by threads, and the outer edge of the slider 5 is provided with a boss 5-2. The clutch driven part includes a left end cover 3, a right end cover 7 and a connecting sleeve 6. The connecting sleeve 6 is sleeved on the power input shaft 1, and the left end cover 3 is fixed on one end of the connecting sleeve 6 by a hexagon socket head cap screw 4 and passed through the left conical roller. The sub-bearing 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com