A contact structure of a commutation-type high-voltage DC contactor

A high-voltage direct current and contactor technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve problems such as complex structure, inability to meet high-voltage and large-current breaking requirements, and low rated current, and achieve reduction Effects of ablation, improving service life, and solving heat problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

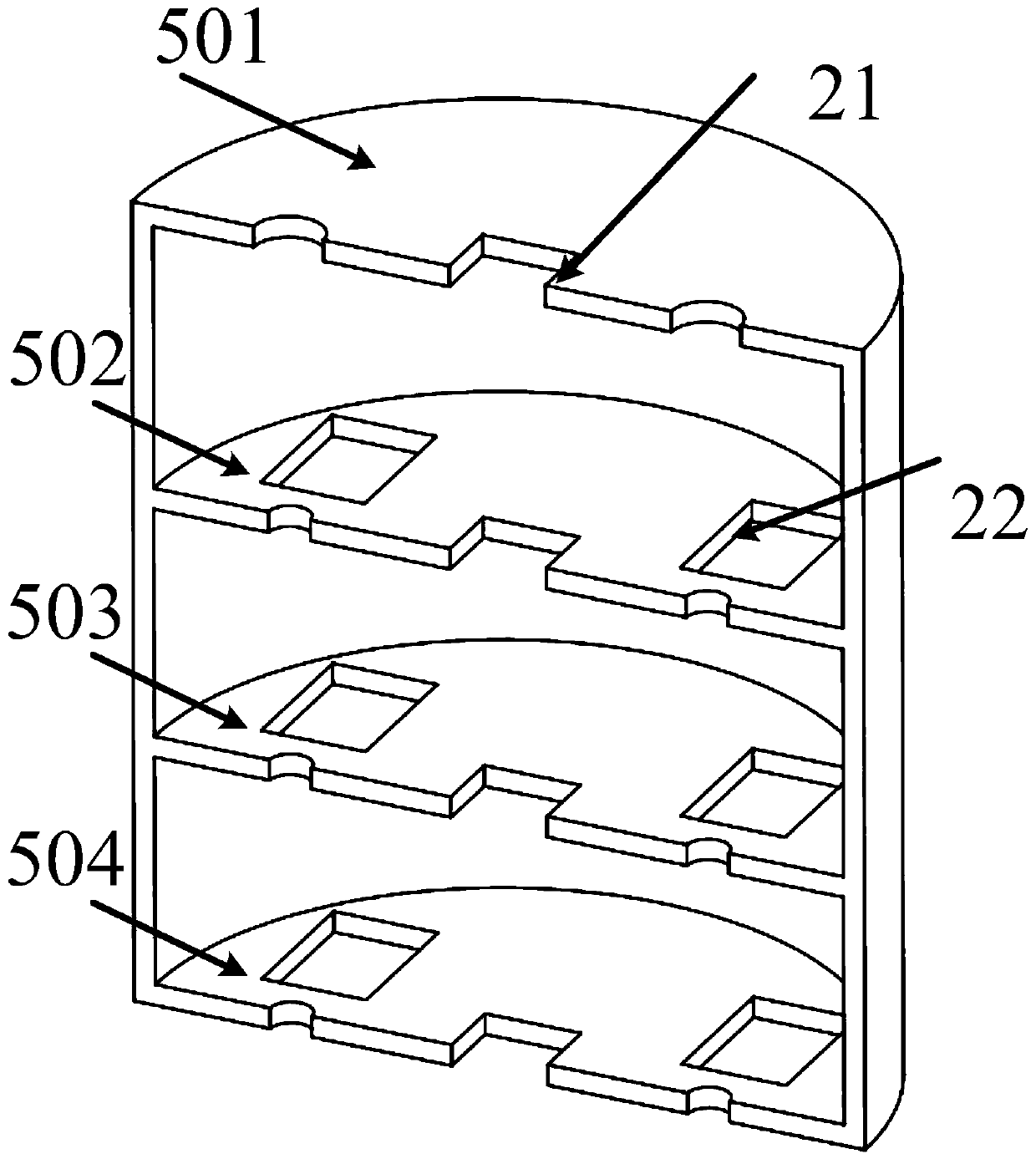

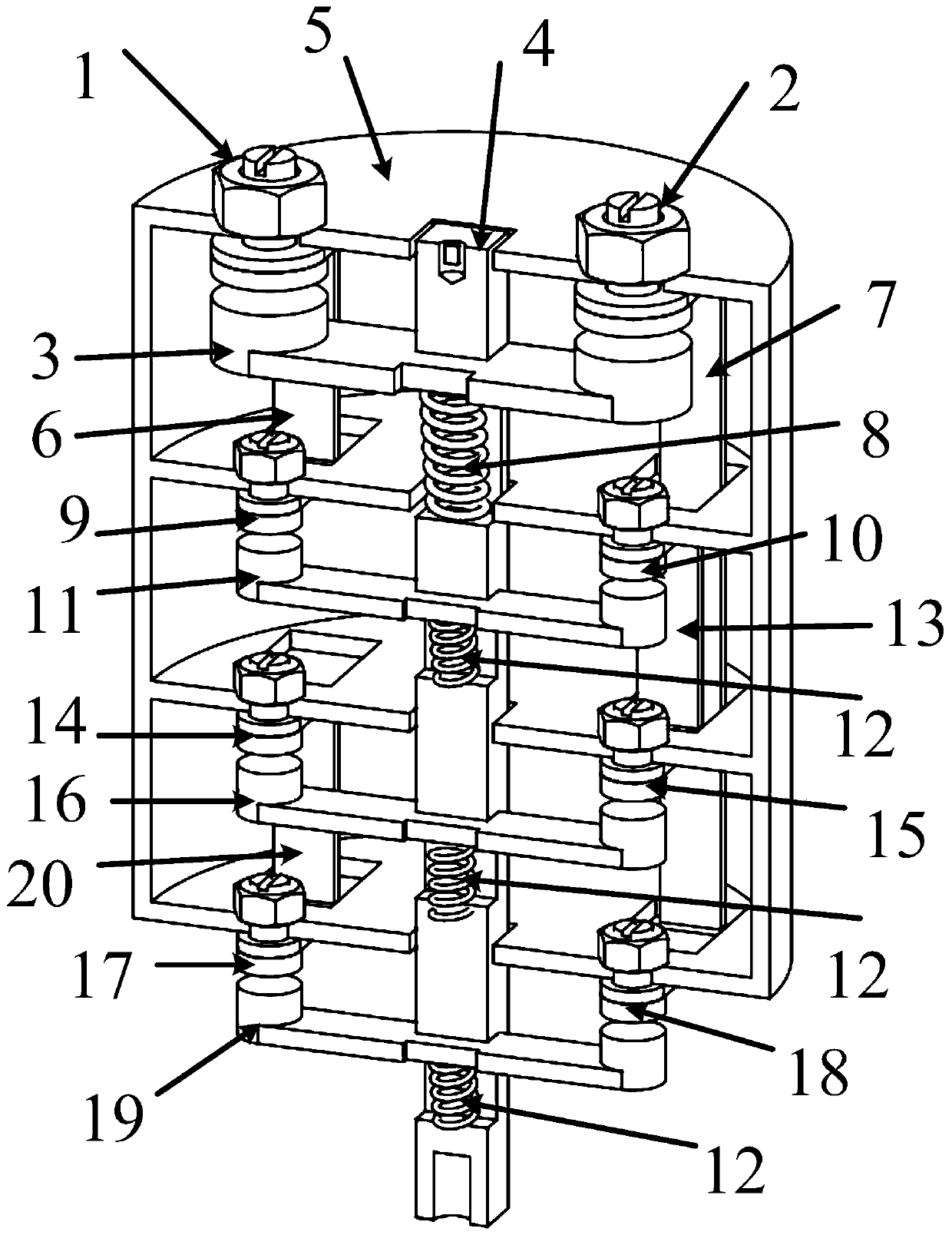

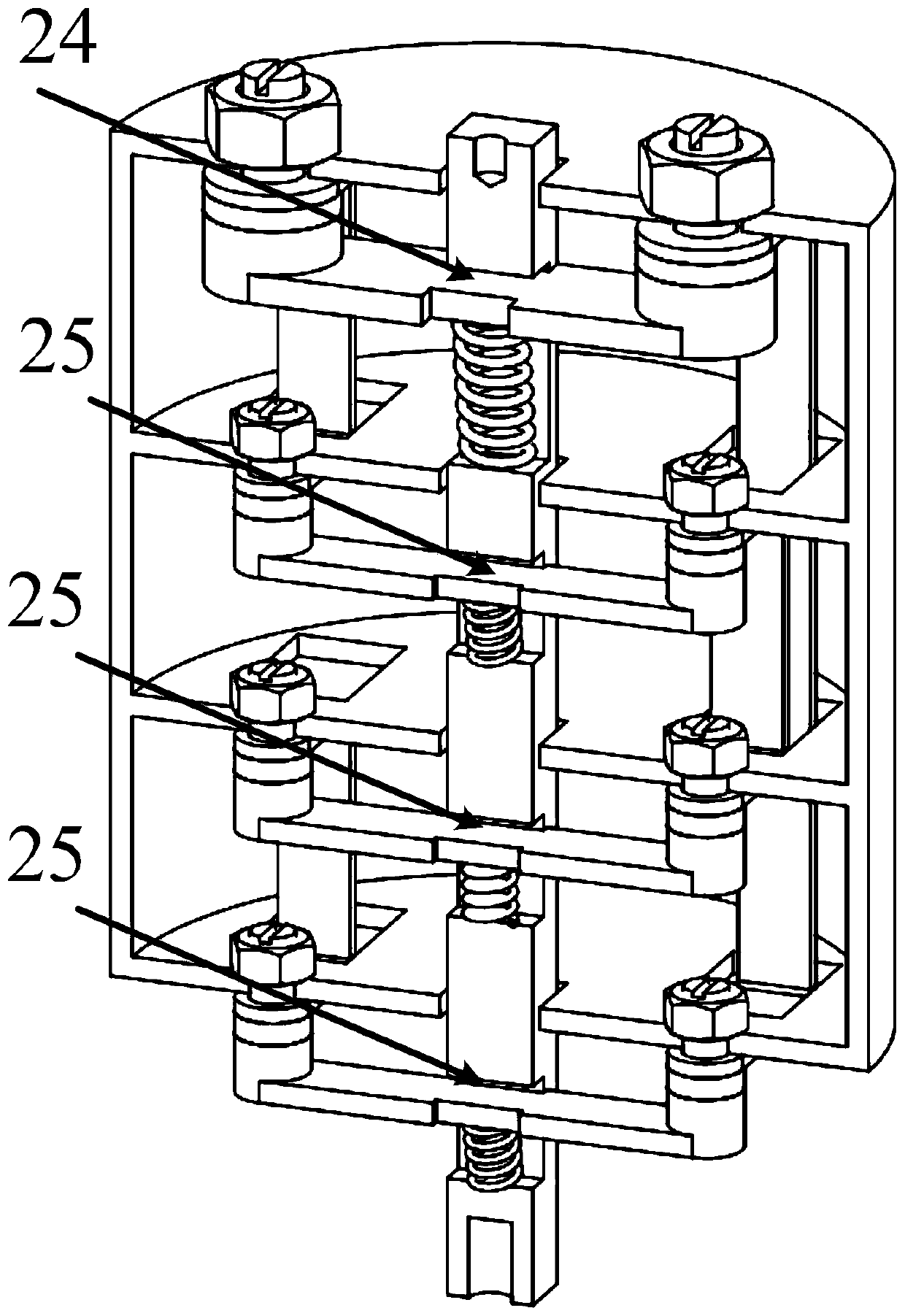

[0026] The invention provides a commutation type high voltage DC contactor contact structure, such as figure 2 As shown, the contact structure consists of the main static contact A 1 1. Main static contact A 2 2 and the active contact M 3 composed of flow branch and arc static contact B 1 9. Arc static contact B 2 10. Arc moving contact H 1 11. Arc static contact C 1 14. Arc static contact C 2 15. Arc moving contact H 2 16. Arc static contact D 1 17. Arc static contact D 2 18. Arc moving contact H 3 19 arc extinguishing branches. The size of the static contacts of the arc-extinguishing branch is smaller than the contact of the flow-through branch, and the flow-through branch and the arc-extinguishing branch pass through the conductive bridge A made of copper 1 B 1 6 and conductive bridge A 2 D. 2 7 to form a paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com