Adsorption Silicon Wafer Coating Rotary Table

An adsorption-type, rotary table technology is applied to devices and coatings that apply liquid to the surface, which can solve the problems of difficult silicon wafers, inconvenient coating, uneven coating, etc. Easy to put and take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

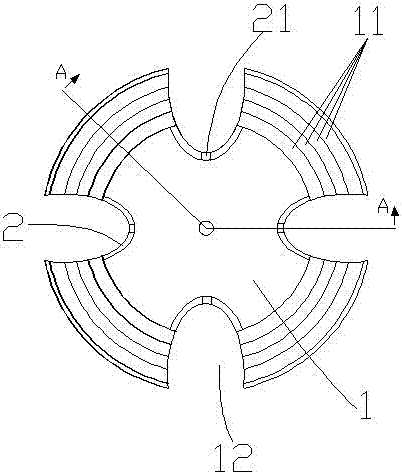

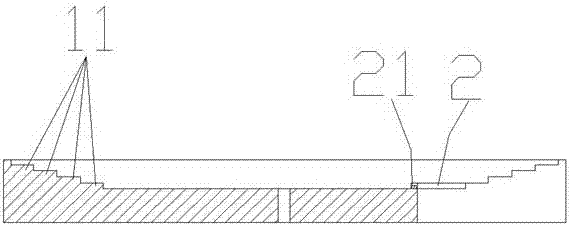

[0013] Such as figure 1 and figure 2 As shown, the specific embodiment of the present invention includes a table top 1, on which a circular platform 11 that is concentric with it and arranged radially in a stepped shape is provided. The height of 11 is the same as the height of the silicon wafer or slightly less than the height of the silicon wafer, so that when coating, the edge of the silicon wafer can also be evenly coated.

[0014] In order to facilitate the taking and placing of silicon wafers, an opening 12 extending toward the center of the circle is provided on the edge of the table 1. The opening 12 is in the shape of a semicircle. Preferably, the opening 12 includes two symmetrically arranged up and down and two symmetrically arranged left and right. In this way, the table top 1 is divided into four blades by the opening 12, which not only facilitates the taking and placing of silicon wafers, but also saves materials and reduces costs.

[0015] In order to generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com