Equipment spare part safety stock calculating method and system

A technology of safety inventory and calculation method, which is applied in the field of safety inventory calculation and system of equipment spare parts, can solve the problems of poor practicality and flexibility, and achieve the effect of reducing the pressure of inventory costs and reducing the risk of material shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

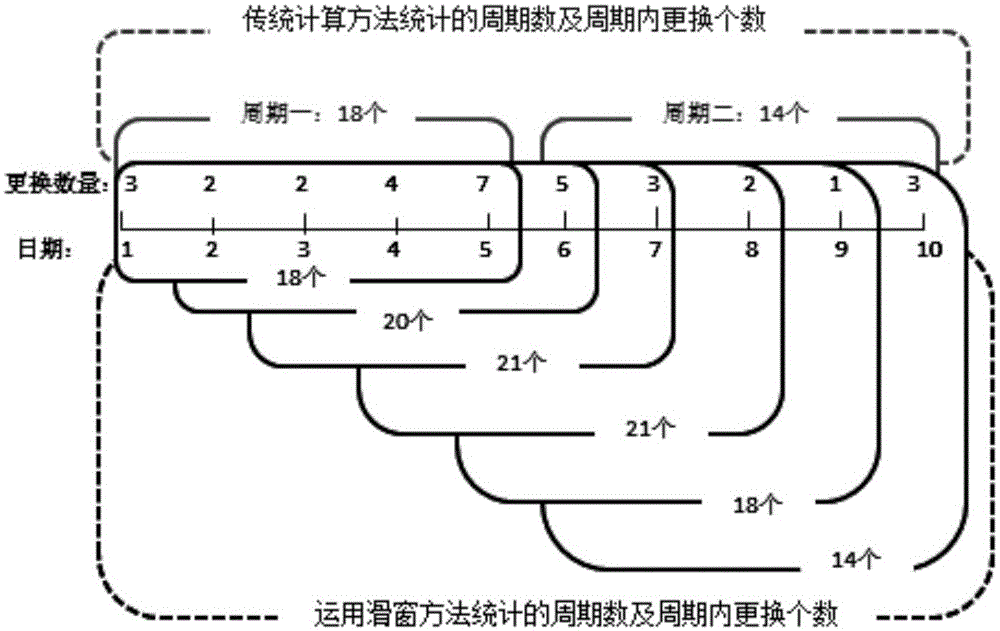

[0044] Such as Figure 1-2 , the method of this law is specifically described as follows:

[0045] (1) Firstly, based on a large amount of historical data recorded in maintenance and replacement parts, based on a flexible adjustable sliding window width (such as 7 days or 30 days, 5 days in this example), make more fine-grained sliding window statistics for each type of spare parts , to obtain the upper and lower limits and average value of the spare parts that need to be consumed in the specified time period;

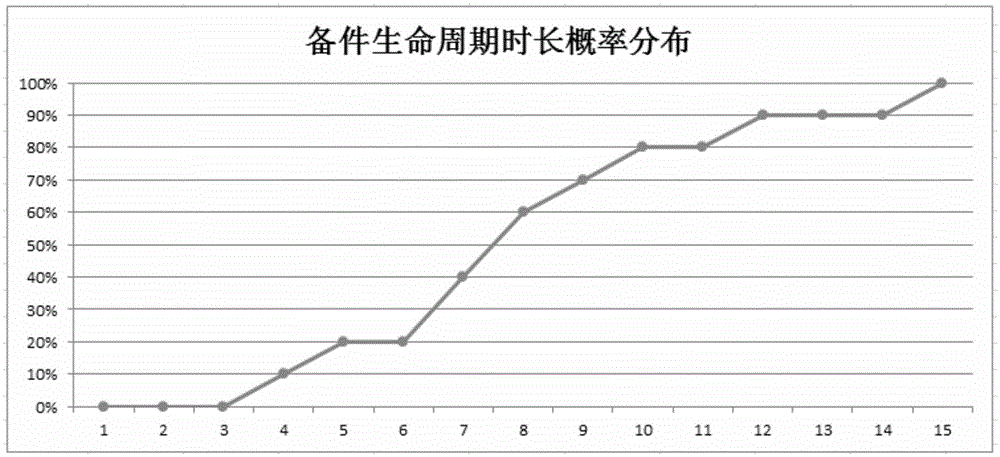

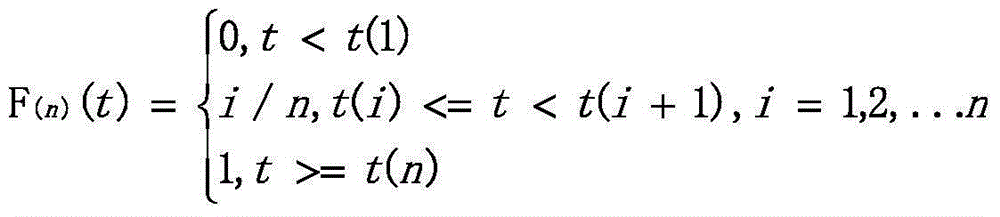

[0046] (2) Based on the idea of MTBF, calculate the time distribution rate characteristics of the comprehensive damage or failure of each type of spare parts in the whole life cycle; the calculation formula is as follows:

[0047] F ( n ) ( t ) = 0 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com