Flange transfer communication tower

A communication tower and flange technology, applied in the field of communication towers, can solve the problems of material waste, complex operation of anchor bolts, and prolonging the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

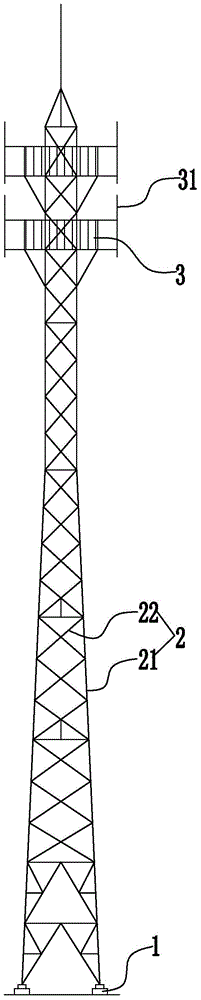

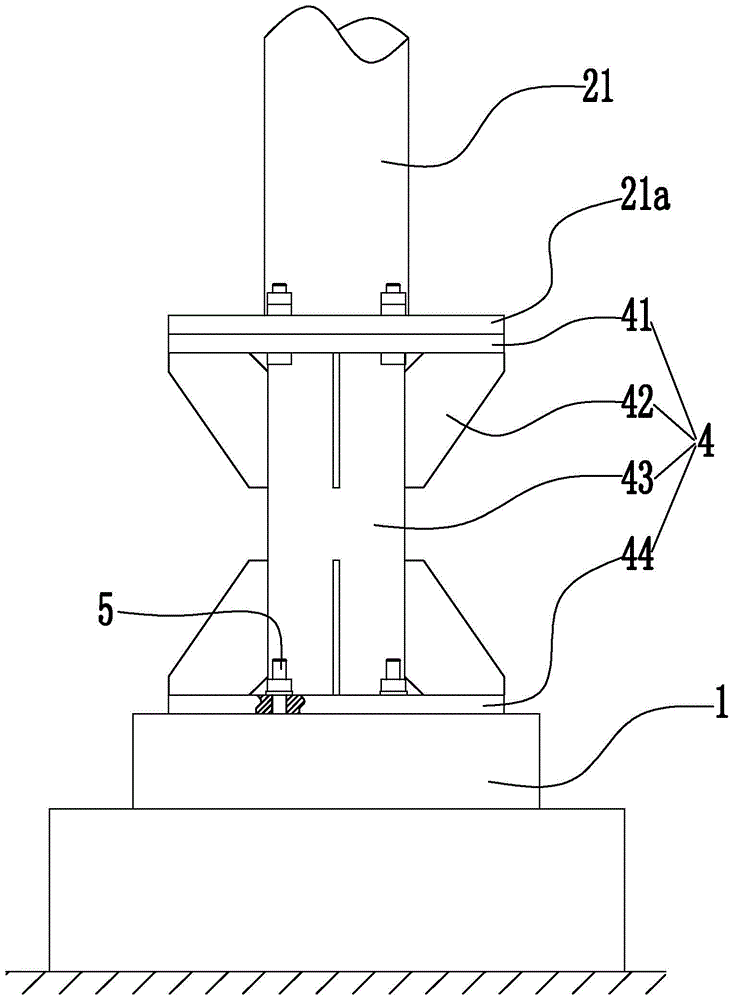

[0033] Embodiment 1: as figure 1 , figure 2 As shown, a flange transfer communication tower includes a base 1 and a tower body 2 arranged on the base. Two maintenance platforms 3 are arranged on the upper part of the tower body, and a plurality of antenna hanging rods 31 for hanging communication antennas are arranged on the outer side of the maintenance platform. The tower body includes three main support towers 21 extending from bottom to top and several connecting towers 22 connecting the two main support towers. The lower end of the main supporting tower rod is connected with the base through the transfer flange structure 4 .

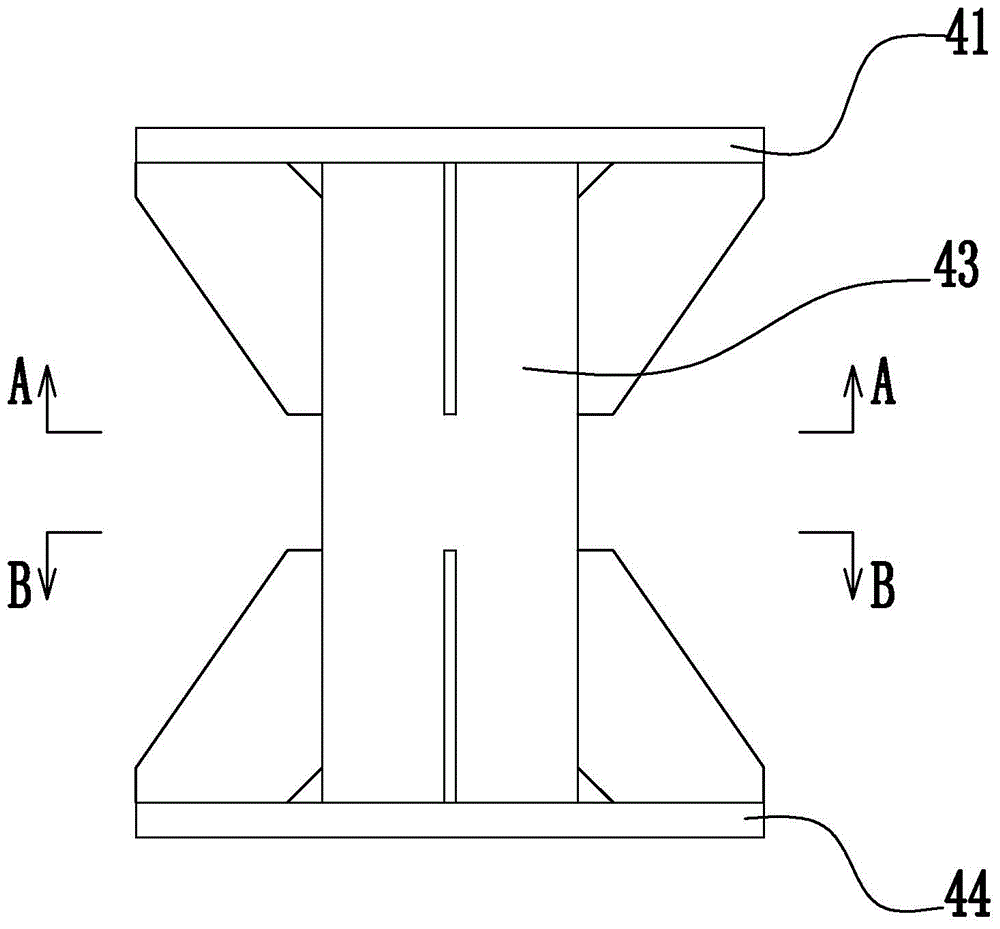

[0034] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, the adapter flange structure includes an upper adapter flange 41 , a lower adapter flange 44 and a connecting pipe 43 connecting the upper adapter flange and the lower adapter flange. Several upper reinforcing plates 42 uniformly distributed in the circumferential direction ...

Embodiment 2

[0036] Embodiment 2: the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

[0037] like Image 6 As shown, a flange transfer communication tower also includes a controller, a trigger rope 6, a connecting rope 8, an installation base 10, and a trigger device 7 and an execution device 9 arranged on the installation base. The triggering device and the actuator are located on the same side of the tower.

[0038] like Image 6 , Figure 7 As shown, the trigger device 7 includes a trigger cylinder 71 vertically arranged on the top surface of the installation base, a trigger piston 73 slidably arranged in the trigger cylinder, and a second trigger cylinder arranged on the side of the trigger cylinder and below the trigger piston. The lower limit block 72 and the pressure sensor 713 arranged in the trigger cylinder and above the trigger piston. The pressure sensor is connected with the controller through the signal line. Trigger the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com