Wheel hub unit negative clearance testing equipment

A technology for testing equipment and hub units, applied in measuring devices, instruments, etc., can solve problems such as vehicle safety hazards, poor repeatability, scratches, etc., and achieve high automation, improved safety performance, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

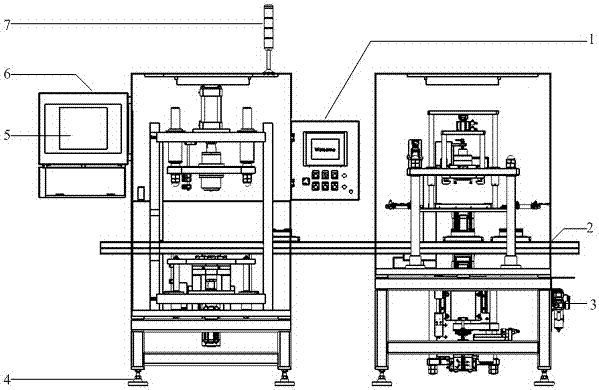

[0022] The wheel hub unit negative clearance detection device of the present invention mainly detects the negative clearance value of the bearing after the inner ring of the wheel hub unit is press-fitted. The invention is divided into two devices, a positive clearance detection device and an inner ring re-pressing device, both of which adopt a frame structure. Such as figure 1 As shown, the main frame of each device is constructed of industrial profiles, and the door on the main frame is installed with plexiglass. When the door is closed, the operating status of the equipment can be observed to play a protective role. The upper end of the main frame door and window is equipped with a safety protection device, which adopts an electronic door lock. Except in the waiting state and the end of work state, the electronic door lock is in the protection state. At this time, if someone opens the door and window of the equipment, the equipment will stop urgently and alarm to protect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com