Passenger train baggage counter top plate structure

A technology for railway passenger cars and luggage racks, which is applied to the direction of the railway roof, etc., which can solve the problems of increased noise in the car, falling off of the Velcro cover strip, and easy damage to the side roof, so as to avoid loosening, increase the aesthetic effect, and improve the aesthetic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

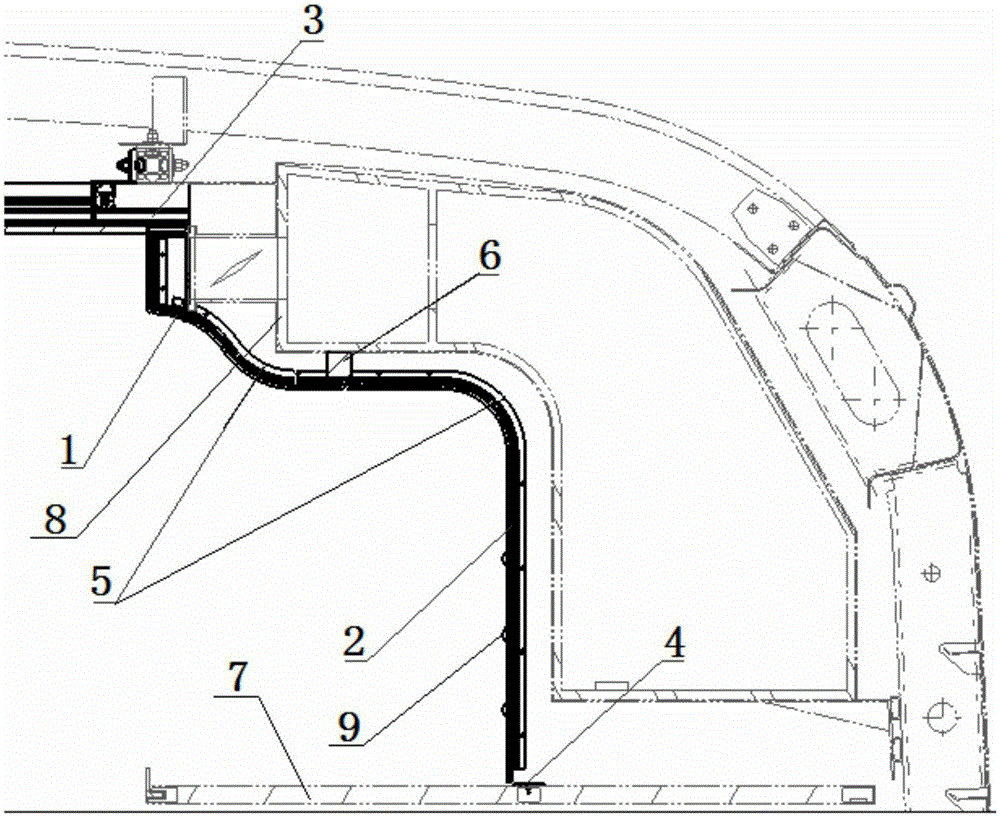

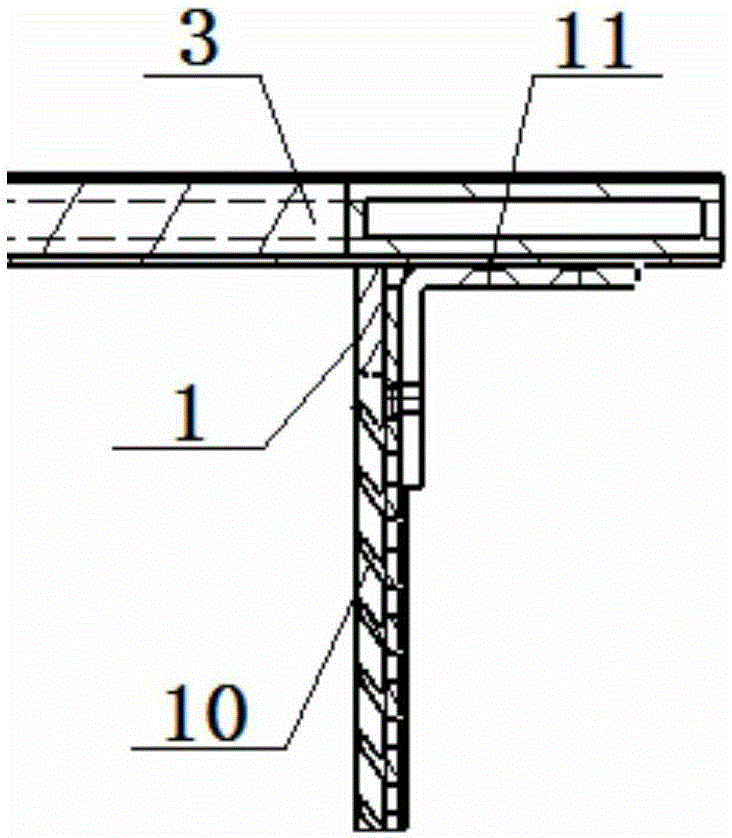

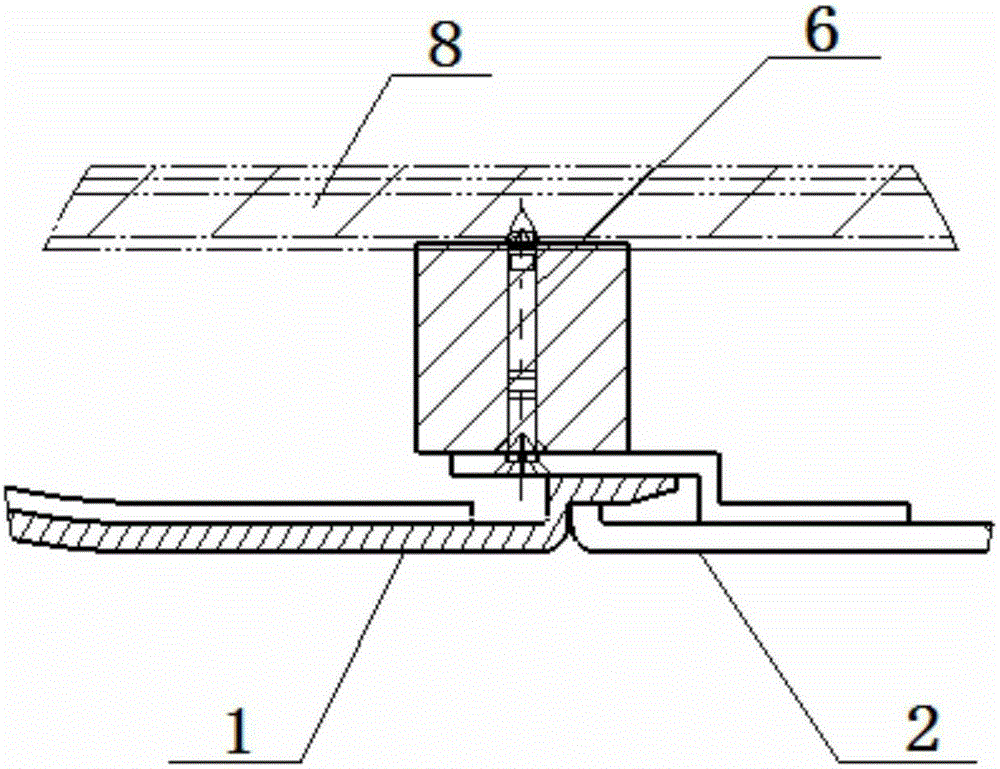

[0019] Such as Figure 1 to Figure 4 As shown, the roof structure of the railway passenger car luggage platform in this embodiment includes a flat roof plate 3, a side roof plate 2, a curved plate 1 that passes through a platform flat roof plate 7, and is fixed to the air outlet grille 10 and is fixed on the vehicle partition wall 14. Aluminum bead 5. The upper end of the side top plate 2 is hoisted below the air-conditioning duct 8 through the wooden lining 6, and the lower end is fixed on the platform top plate 7 through the connecting angle iron 4. The curved plate 1 is provided with a rectangular hole matching the peripheral size of the air outlet grille 10, and the air outlet grille 10 is embedded in the rectangular hole, and fixed with the curved plate 1 by glue to make the outer surface smooth. Such as figure 2 As shown, the upper end of the curved plate 1 is fixed below the flat roof panel 3 by connecting iron 11 . Such as image 3 As shown, the lower end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com