Rapid mesh division method for hexagonal integrated multi-opening superstructure of ship

A superstructure and grid division technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of time-consuming and huge grid division workload, so as to improve the grid division speed and save Effects of Meshing Operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

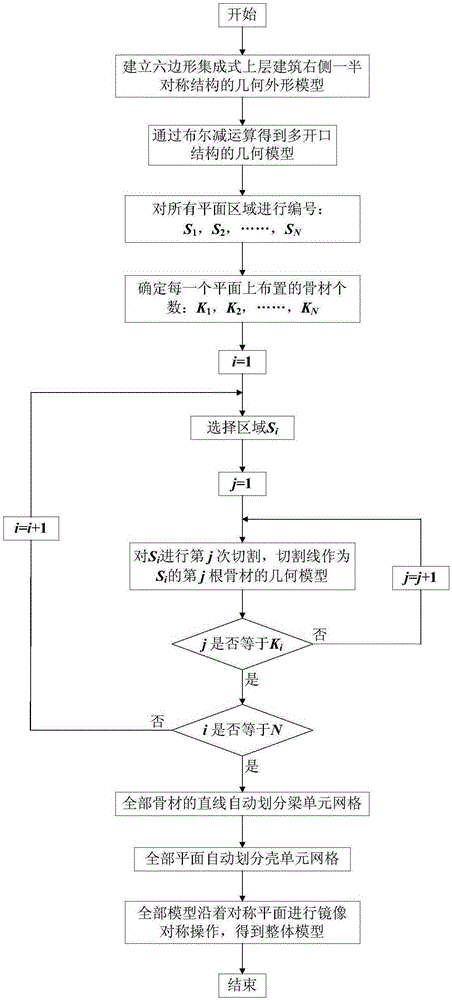

Method used

Image

Examples

Embodiment

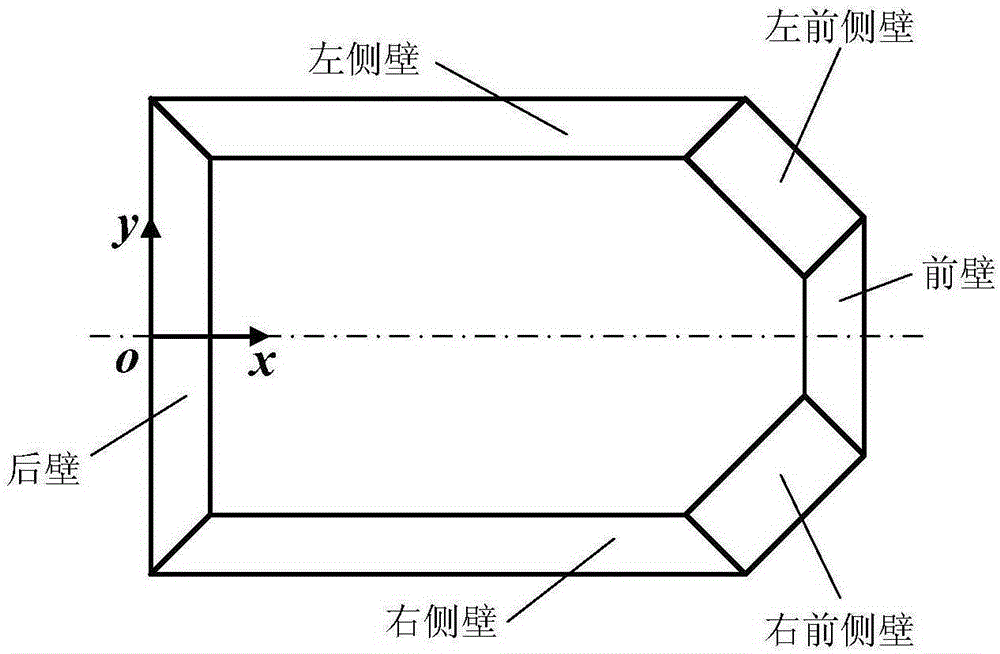

[0085] In order to fully understand the characteristics of the invention and its applicability to engineering practice, the present invention is aimed at the hexagonal integrated multi-opening ship superstructure, under the situation of a total of 10 openings in the half symmetrical structure on the right side, (the overall model totals 20 openings), using ANSYS commercial finite element software for fast meshing to verify the effectiveness and applicability of this method.

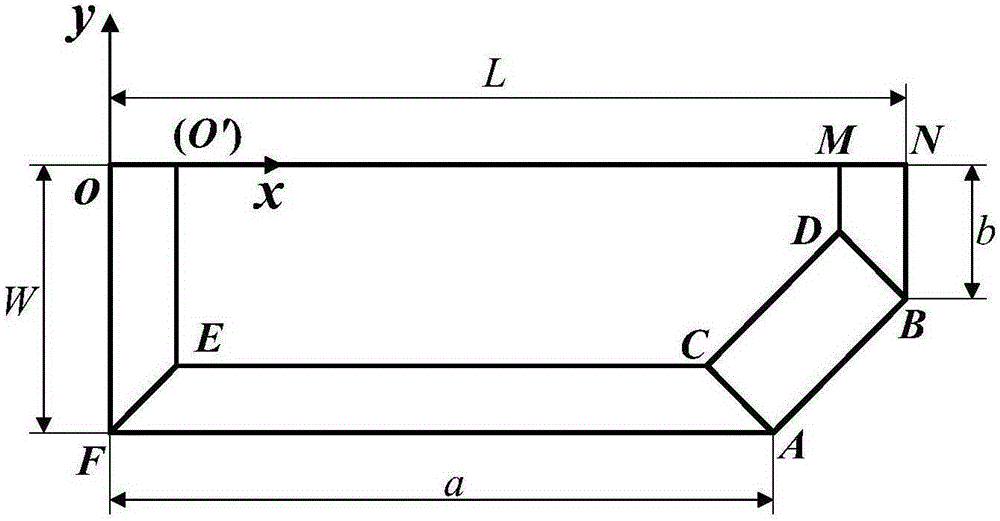

[0086] refer to image 3 , Figure 5 , Figure 6 , the basic parameters of the superstructure are selected as follows:

[0087] Maximum length: L=30m;

[0088] Maximum width (half symmetrical structure on the right): W=8.5m;

[0089] Maximum length of side wall: a=25.5m;

[0090] The maximum width of the front wall (half symmetrical structure on the right side): b=4m;

[0091] Maximum height: H=12.5m;

[0092] The superstructure has a total of 6 decks, and the heights between adjacent decks are equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com