Vapor Deposition Device

A technology of vapor phase growth and components, which is applied in the direction of electrical components, gaseous chemical plating, vacuum evaporation plating, etc., can solve problems such as costing a lot of effort and time, and gear chipping, so as to achieve automatic disassembly and assembly, reliable transition, Eliminates the effect of meshing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

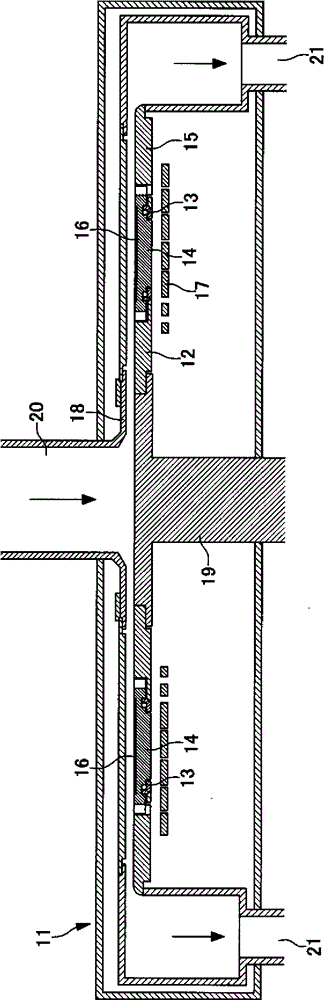

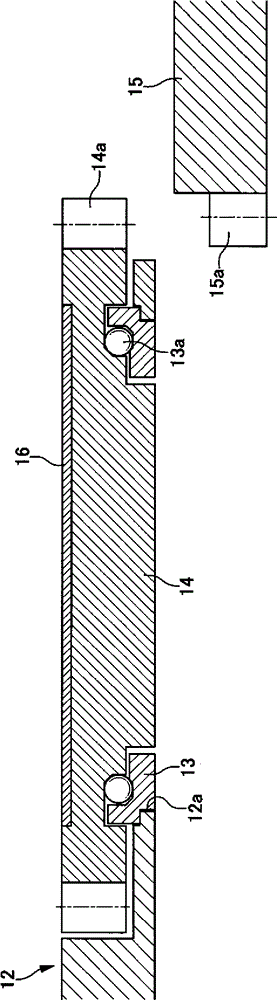

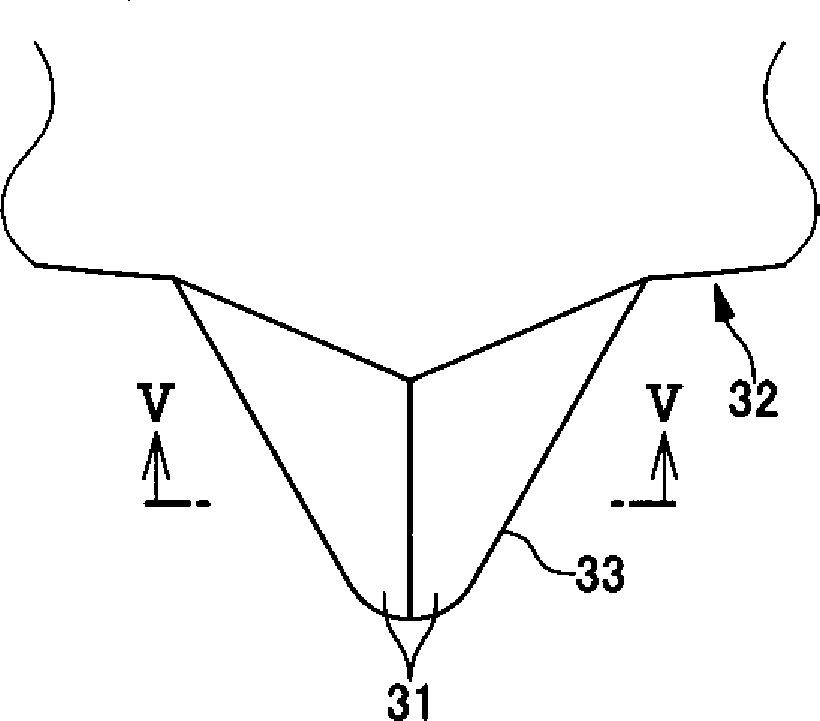

[0027] Figure 1 to Figure 8 The vapor phase growth apparatus shown is for showing the first embodiment of the present invention. The vapor-phase growth apparatus is provided with a base 12 in such a way that the disk-shaped base 12 can rotate in the chamber 11, and includes: ring-shaped bearing members 13, which are respectively arranged on the sides of the base 12. In a plurality of circular openings 12a formed in the circumferential direction of the outer peripheral portion; an external gear member (rotation base) 14 is mounted on each bearing in a rotatable manner by means of a plurality of rolling members (balls) 13a member 13; an annular fixed internal gear member 15 meshing with the external gear member 14; device) 17; a flow channel (flow channel) 18 that guides the raw material gas in a direction parallel to the surface of the above-mentioned substrate 16.

[0028] A shaft member 19 for rotating the base 12 is provided at the lower central portion of the base 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com