Cold and hot air hose valve

An air duct valve, cooling and heating technology, applied in the field of air duct valves, can solve the problems of potential safety hazards and large air leakage, and achieve the effect of good sealing and consistent air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

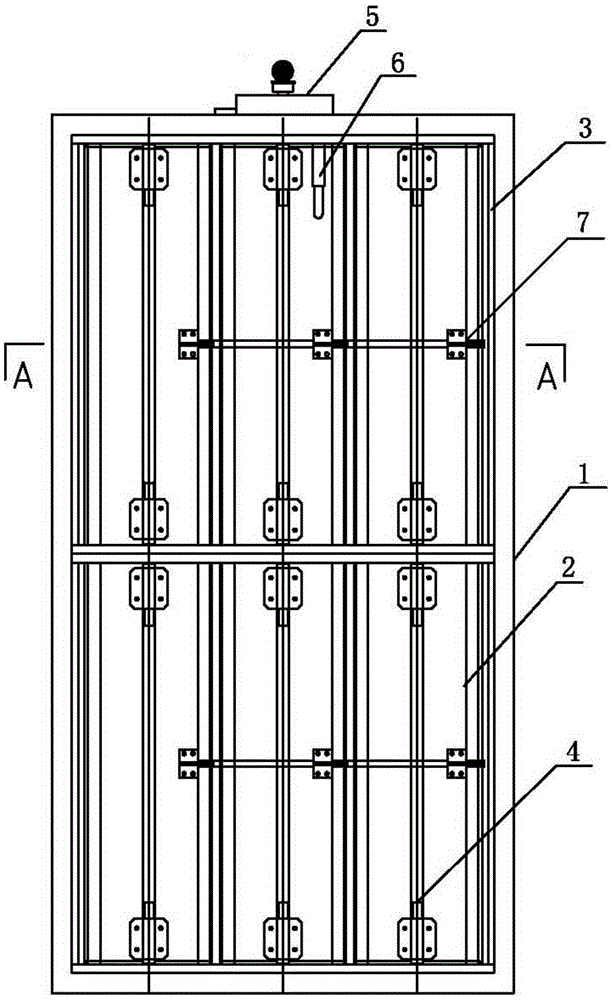

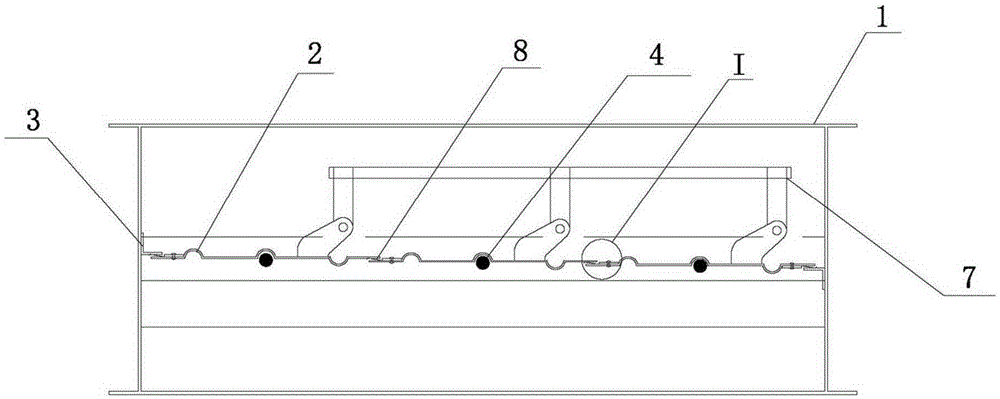

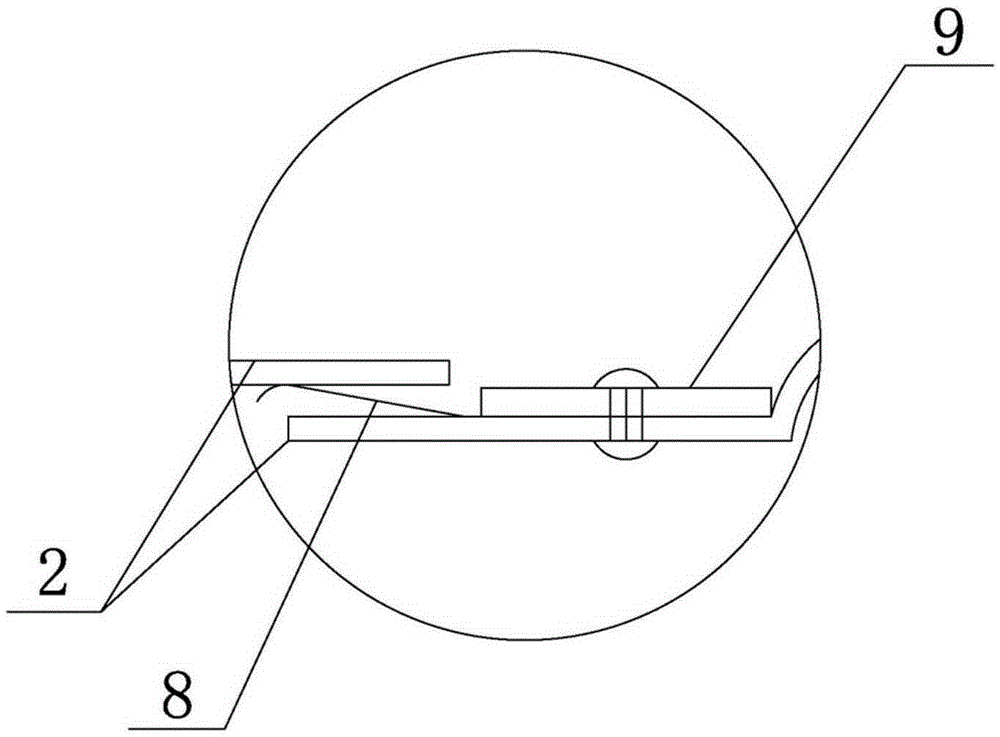

[0026] Refer to attached Figure 1~4 , a cold and hot air duct valve, the hot and cold air duct valve includes a valve body 1, blades 2, bar 3, blade shaft 4, actuator 5, temperature sensor 6, connecting rod 7, reed 8 and fixed Part 9, wherein the valve body 1 has a "day"-shaped structure, six blades 2 are fixed in the valve body 1; the blade shaft 4 is fixed in the valve body 1, the blade 2 is matched with the blade shaft 4, and the blade 2 4 is driven to rotate; the blades 2 are connected through the connecting rod 7 to realize linkage, and the opening and closing of the blades 2 are controlled by the actuator 5; the temperature sensor 6 is fixed on the valve body 1; the reed 8 adopts high temperature resistant material, the reed 8 is composed of piece 1 8a and piece 2 8b, piece 1 8a and piece 2 8b are integrally made, piece 1 8a of reed 8 is fixed with blade 2, piece 2 8b is set obliquely, piece 2 The end of 8b is provided with curved piece 8b1, increases contact area, imp...

Embodiment 2

[0028] Refer to attached figure 1 , 5 ~8, a cold and hot air duct valve, the hot and cold air duct valve includes a valve body 1, six blades 2, six blade shafts 4, an actuator 5, a temperature sensor 6, a connecting rod 7, a reed 8 and Fixing piece 9, wherein, the vane shaft 4 is fixed in the valve body 1, the vane 2 cooperates with the vane shaft 4, and the vane 2 rotates under the drive of the vane shaft 4; the linkage between the vanes 2 is realized by connecting the connecting rod 7, and the vane The opening and closing of 2 are controlled by the actuator 5; the temperature sensor 6 is fixed on the valve body 1; the reed 8 is made of a high temperature resistant material, and the reed 8 is composed of a piece 8a and a piece 2 8b, and the piece 8a It is integrally made with sheet 2 8b, sheet 1 8a of reed 8 is fixed with blade 2, sheet 2 8b is arranged obliquely, reed 8 is arranged between blade 2 and blade 2, and sheet 1 of said reed 8 8a is provided with fixing hole 8c, ...

Embodiment 3

[0030] Refer to attached figure 1 , 9 and 10, a cold and hot air duct valve, which comprises a valve body 1, six blades 2, six blade shafts 4, an actuator 5, a temperature sensor 6, a connecting rod 7, a reed 8 and The fixing part 9, wherein, the vane shaft 4 is fixed in the valve body 1, the vane 2 is matched with the vane shaft 4, and the vane 2 rotates under the drive of the vane shaft 4; 7 connection to achieve linkage, the opening and closing of the blade 2 is controlled by the actuator 5; the temperature sensor 6 is fixed on the valve body 1; the reed 8 is made of high temperature resistant material, and the reed 8 is composed of a piece 8a and a piece 2 8b, sheet one 8a and sheet two 8b are integrally made, sheet one 8a of reed 8 is fixed with blade 2, sheet two 8b is arranged obliquely, reed 8 is provided between blade 2 and blade 2, and the Sheet one 8a of reed 8 is provided with fixing hole 8c, and described fixture 9 is sheet shape, and sheet one 8a is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com