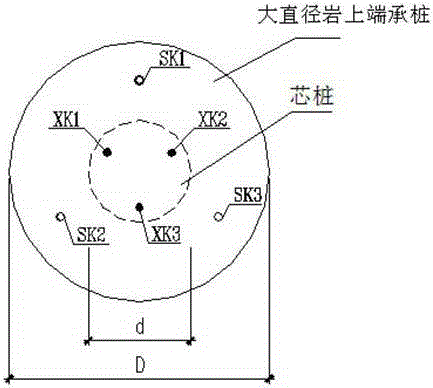

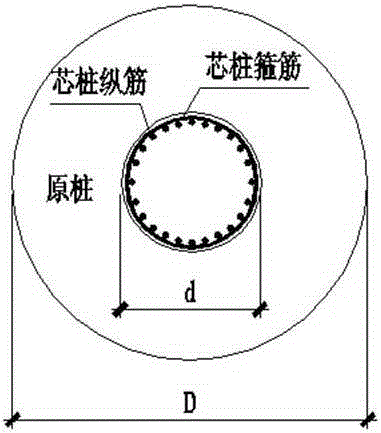

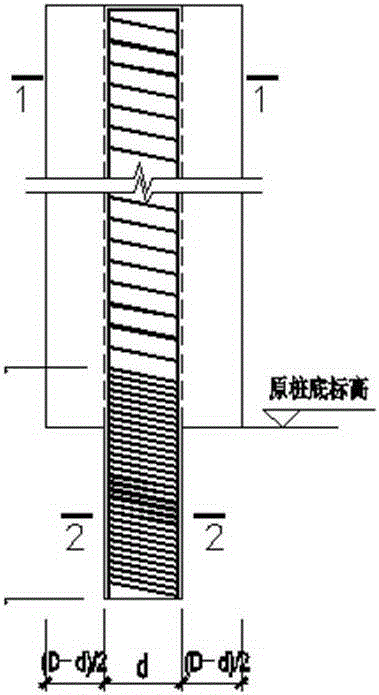

Method for detecting and reinforcing vertical bearing force of defective large-diameter socketed pile

A technology with large diameter and bearing capacity, which is used in the test of foundation structure, repair of foundation structure, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The following is an example of a project in Liuzhou City, Guangxi Zhuang Autonomous Region

[0064] Taking a certain project in Liuzhou City as an example, the building is a super high-rise apartment-style office building with a height of 208m above the ground. End resistance standard value is 20000kPa, and the characteristic value of the design single pile bearing capacity is 59000kN. If the static load test is adopted, the pile pressure force should not be less than 118000kN. Integrity testing of the pile body is carried out using the method, and no less than 10% of the total number of piles and no less than 10 engineering piles are randomly selected for core drilling inspection to detect the integrity of the pile body, concrete strength, thickness of pile tip sediment, and pile tip rock formation. Integrity and core strength etc. In view of the fact that the rock-socketed piles of this project are mainly end-bearing, if the sediment at the pile end is too thick, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com