Formed ligneous body and method of producing the same

A manufacturing method and a technology of shaped bodies, which are applied in the direction of wood layered products, chemical instruments and methods, and other household appliances, can solve problems such as poor adhesion, peeling, and damage to the transparent layer, and achieve improved light transmission and improved Adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

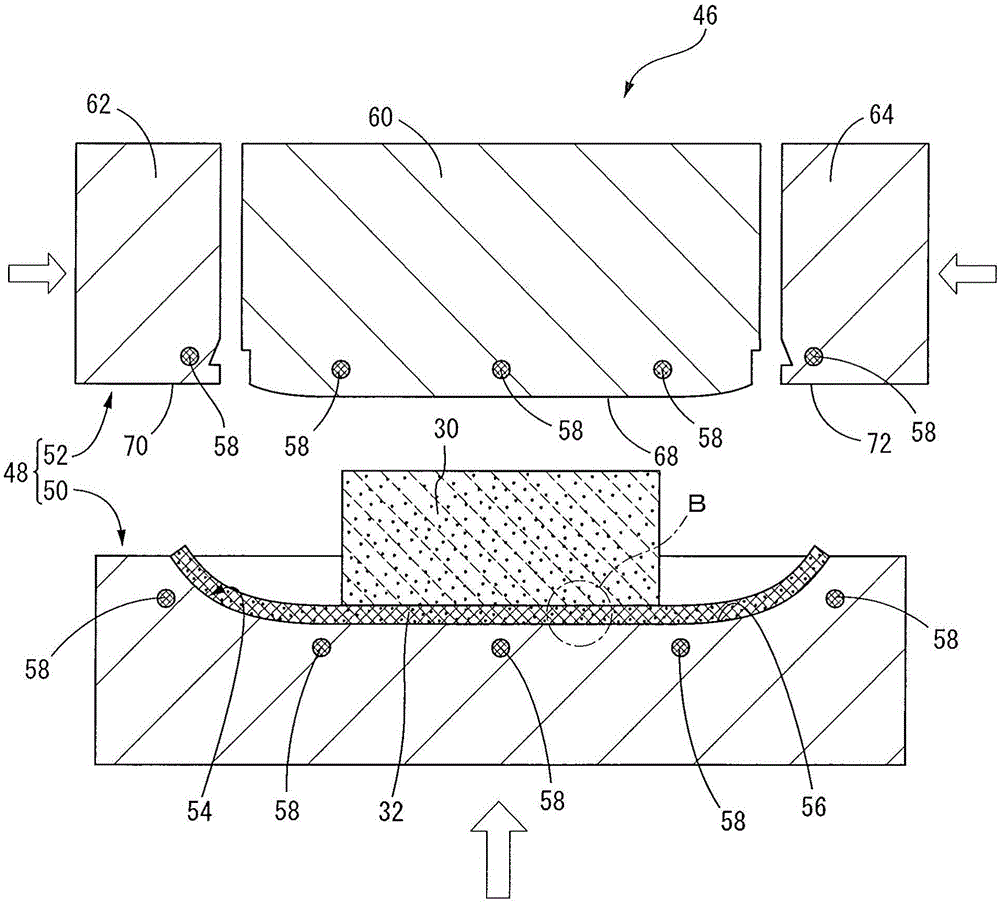

[0069] Hereinafter, in order to clarify this invention more concretely, embodiment of this invention is described in detail, referring drawings.

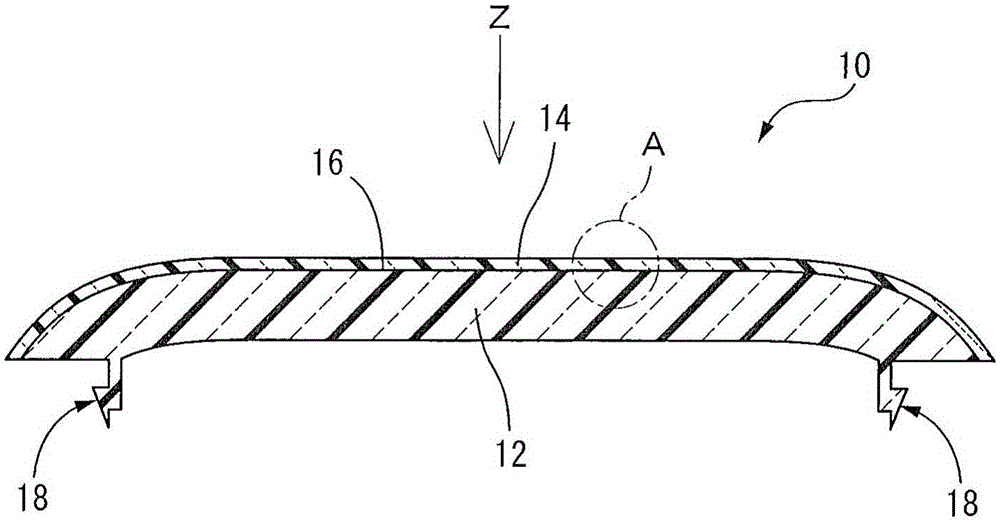

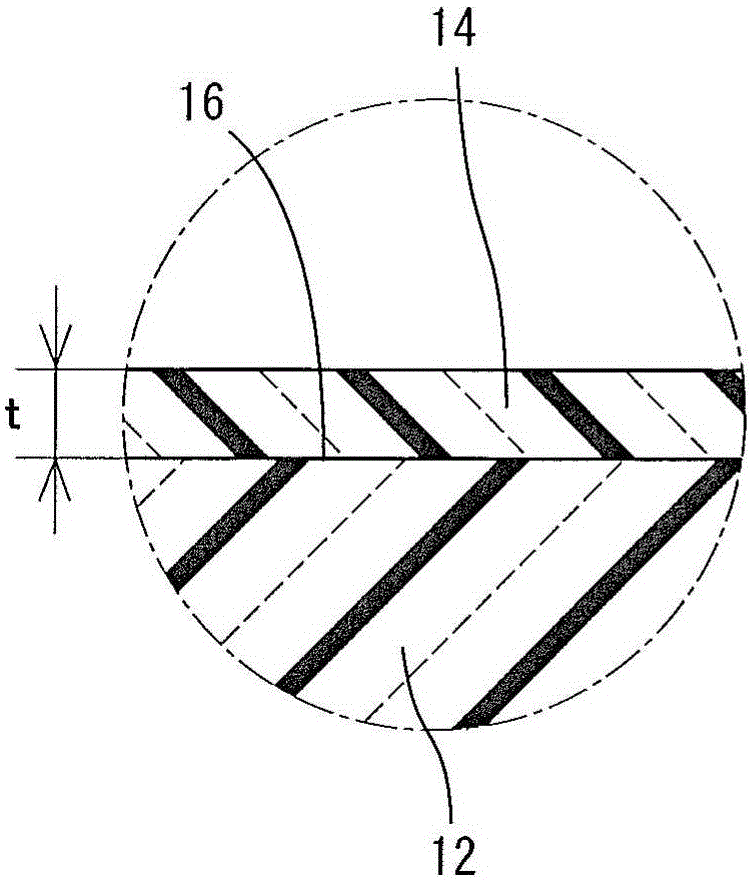

[0070] First, in figure 1 and figure 2 In FIG. 1 , one embodiment of an automotive interior part, which is a wooden molded article of the present invention, is shown in cross-sectional form. As is clear from these drawings, the automotive interior component 10 of the present embodiment (hereinafter simply referred to as the interior component 10) as a whole has a planar shape of a substantially elongated rectangular thick plate, and the wooden base material 12 It is integrally formed with the transparent layer 14 .

[0071] More specifically, the wooden base material 12 is composed of the remaining thickness portion except the transparent layer 14 provided on the surface of the interior member 10, the surface ( figure 1 The entire surface of the upper surface) is set as the appearance surface 16 in the form of a curved surface, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com