Wooden shaped body and manufacturing method thereof

一种制造方法、成形体的技术,应用在木层状制品、化学仪器和方法、其他家里用具等方向,能够解决粘合性不良、剥落、透明层破损等问题,达到提高透光性、提高粘合性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

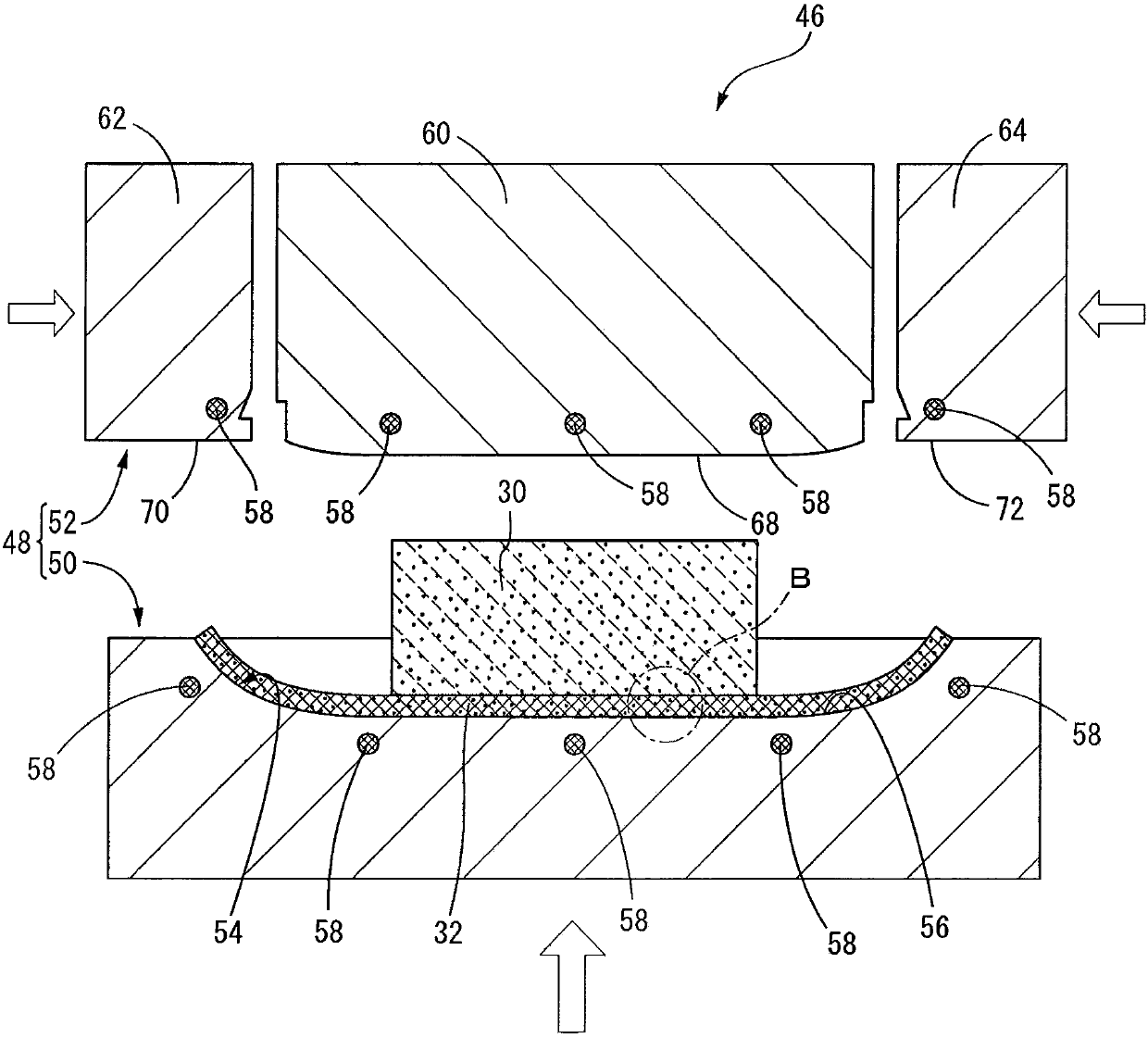

[0069] Hereinafter, in order to clarify this invention more concretely, embodiment of this invention is described in detail, referring drawings.

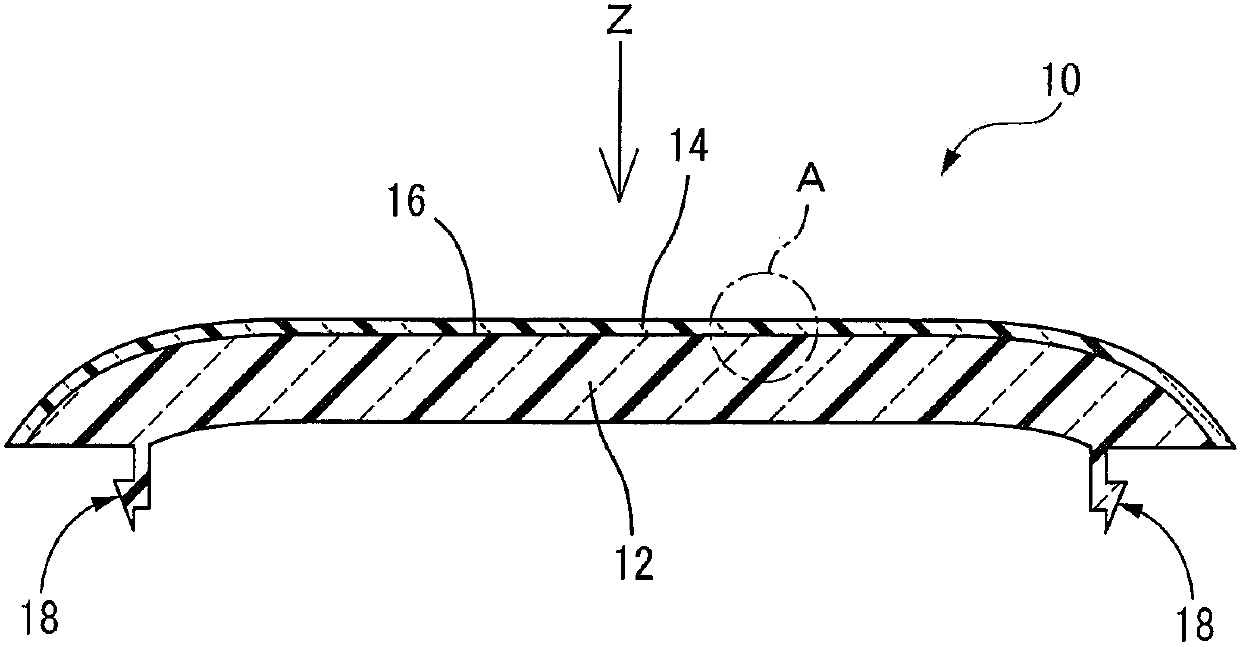

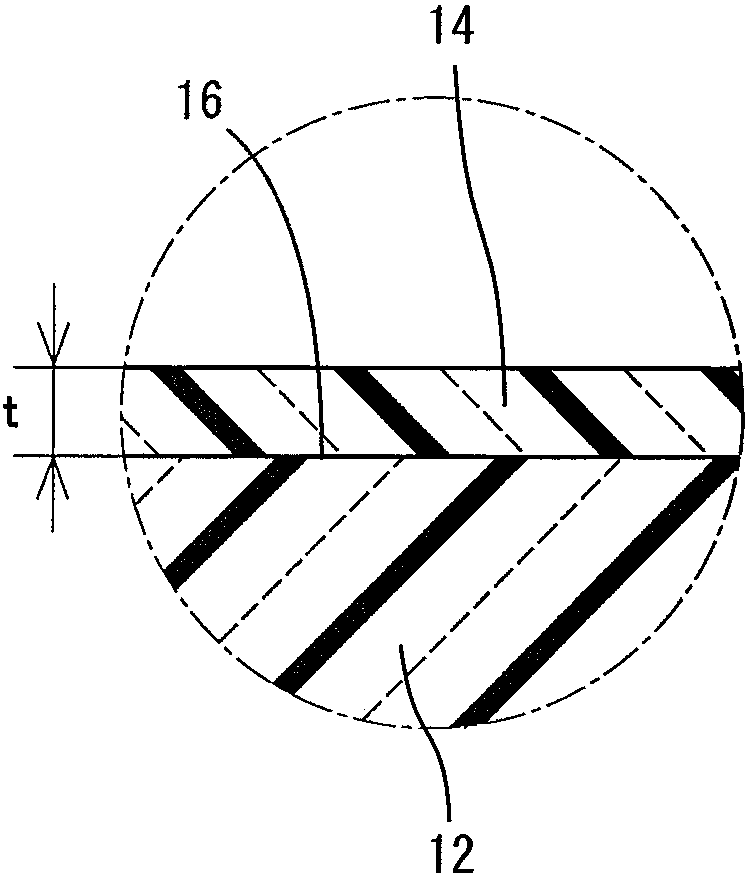

[0070] First, in figure 1 and figure 2 In FIG. 1 , one embodiment of an automotive interior part, which is a wooden molded article of the present invention, is shown in cross-sectional form. As is clear from these drawings, the automotive interior component 10 of the present embodiment (hereinafter simply referred to as the interior component 10) as a whole has a planar shape of a substantially elongated rectangular thick plate, and the wooden base material 12 It is integrally formed with the transparent layer 14 .

[0071] More specifically, the wooden base material 12 is composed of the remaining thickness portion except the transparent layer 14 provided on the surface of the interior member 10, the surface ( figure 1 The entire surface of the upper surface) is set as the appearance surface 16 in the form of a curved surface, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com