A kind of red mud-based sintered lightweight aggregate and preparation method thereof

A light aggregate and red mud technology, which is applied in the field of red mud-based sintered light aggregate and its preparation, can solve the problems of high cost of valuable metals, efflorescence in the production of sintered bricks, secondary pollution, etc., and achieve the suppression of radioactivity and the preparation process Simple, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

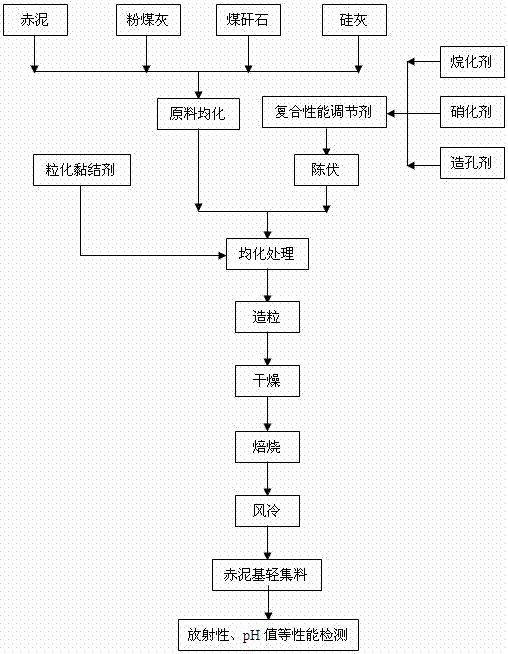

Image

Examples

Embodiment 1

[0017] A red mud-based sintered light aggregate, which is composed of the following raw materials: weigh 40 parts of red mud, 30 parts of fly ash, 20 parts of coal gangue, and 10 parts of silica fume by weight on a dry basis; sodium lauryl sulfate 10 parts, 30 parts of sodium nitrate, 60 parts of pulverized coal of fineness 500 orders, 20 parts of granulated binder, wherein, granulated binder is the mixed solution of water and water glass, and its mass ratio is 75: 25, and wherein, water The glass modulus is 2.0~3.2.

[0018] The preparation method of the above-mentioned red mud-based sintered light aggregate comprises the following steps:

[0019] (1) Raw material treatment: Weigh red mud, fly ash, coal gangue and silica fume in parts by weight on a dry basis, and mix them evenly in a mixer;

[0020] (2) Preparation of composite performance modifier: Weigh sodium lauryl sulfate, sodium nitrate, coal powder with a fineness of 500 mesh, mix well, and then stand at 50°C for 2 d...

Embodiment 2

[0025] A red mud-based sintered light aggregate, which is composed of the following raw materials: weigh 60 parts of red mud, 20 parts of fly ash, 15 parts of coal gangue, and 5 parts of silica fume by weight on a dry basis; sodium lauryl sulfate 20 parts, potassium nitrate 20 parts, fineness 500 mesh pulverized coal 55 parts, granulated binder 10 parts, wherein, granulated binder is the mixed solution of water and water glass, and its mass ratio is 85: 15, and wherein, water The glass modulus is 2.0~3.2.

[0026] The preparation method of the above-mentioned red mud-based sintered light aggregate comprises the following steps:

[0027] (1) Raw material treatment: Weigh red mud, fly ash, coal gangue and silica fume in parts by weight on a dry basis, and mix them evenly in a mixer;

[0028] (2) Preparation of composite performance regulator: weigh sodium lauryl sulfate, potassium nitrate, and coal powder with a fineness of 500 mesh, mix well, and then stand at 65°C for 2 days;...

Embodiment 3

[0033] A red mud-based sintered light aggregate, which is composed of the following raw materials: weigh 80 parts of red mud, 10 parts of fly ash, 5 parts of coal gangue, and 5 parts of silica fume by weight on a dry basis; sodium lauryl sulfate 20 parts, 5 parts of sodium nitrate, 30 parts of fineness 500 mesh pulverized coal, 30 parts of granulated binder, wherein, granulated binder is the mixed solution of water and water glass, and its mass ratio is 90: 10, and wherein, water The glass modulus is 2.0~3.2.

[0034] The preparation method of the above-mentioned red mud-based sintered light aggregate comprises the following steps:

[0035] (1) Raw material treatment: Weigh red mud, fly ash, coal gangue and silica fume in parts by weight on a dry basis, and mix them evenly in a mixer;

[0036] (2) Preparation of composite performance modifier: Weigh sodium dodecylsulfonate, sodium nitrate, coal powder with a fineness of 500 mesh, mix well, and then stand at 80°C for 2 days; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com