Method for improving thickness stability of low-dielectric film

A low-dielectric, stable technology, used in circuits, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as poor stability of low-dielectric film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

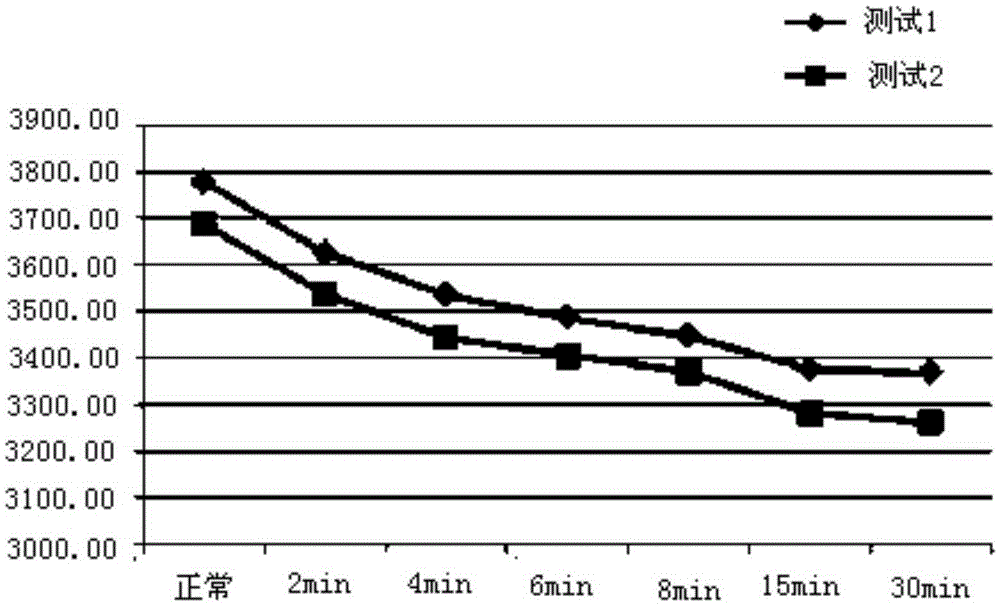

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

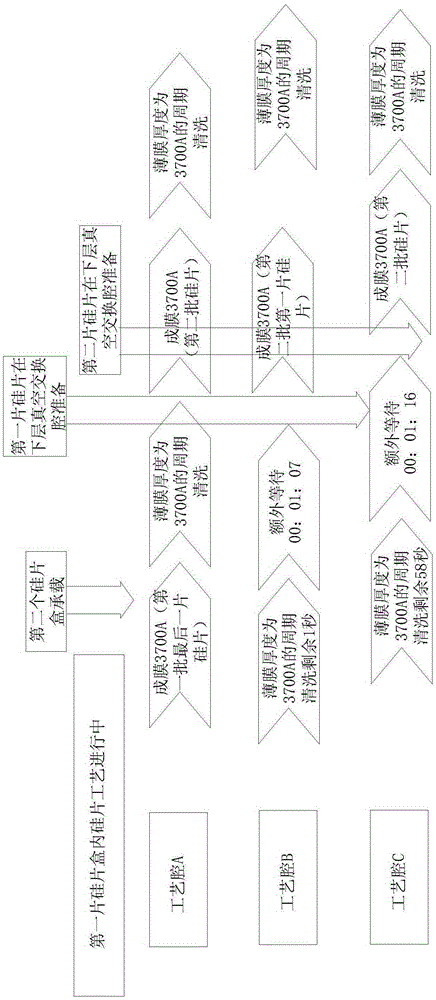

[0032] In the present invention, the number of silicon wafers remaining in the unfinished process is taken as one of the input inspection conditions, and the input inspection conditions are increased to avoid some waiting situations in the process chamber.

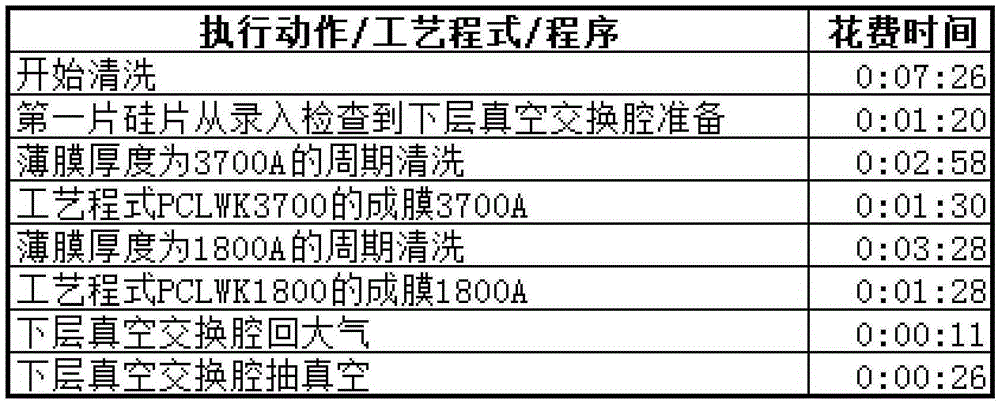

[0033] Figure 4 It is a schematic diagram of an embodiment of a method for improving the stability of a low-dielectric film thickness in the present invention; as Figure 4 As shown, the present embodiment is a method for improving the stability of low-dielectric film thickness. The method includes: step S1: check the number of silicon wafers that have not completed the process in the previous task of the film forming equipment; step S2: remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com