Vehicle Speed Sensing Device

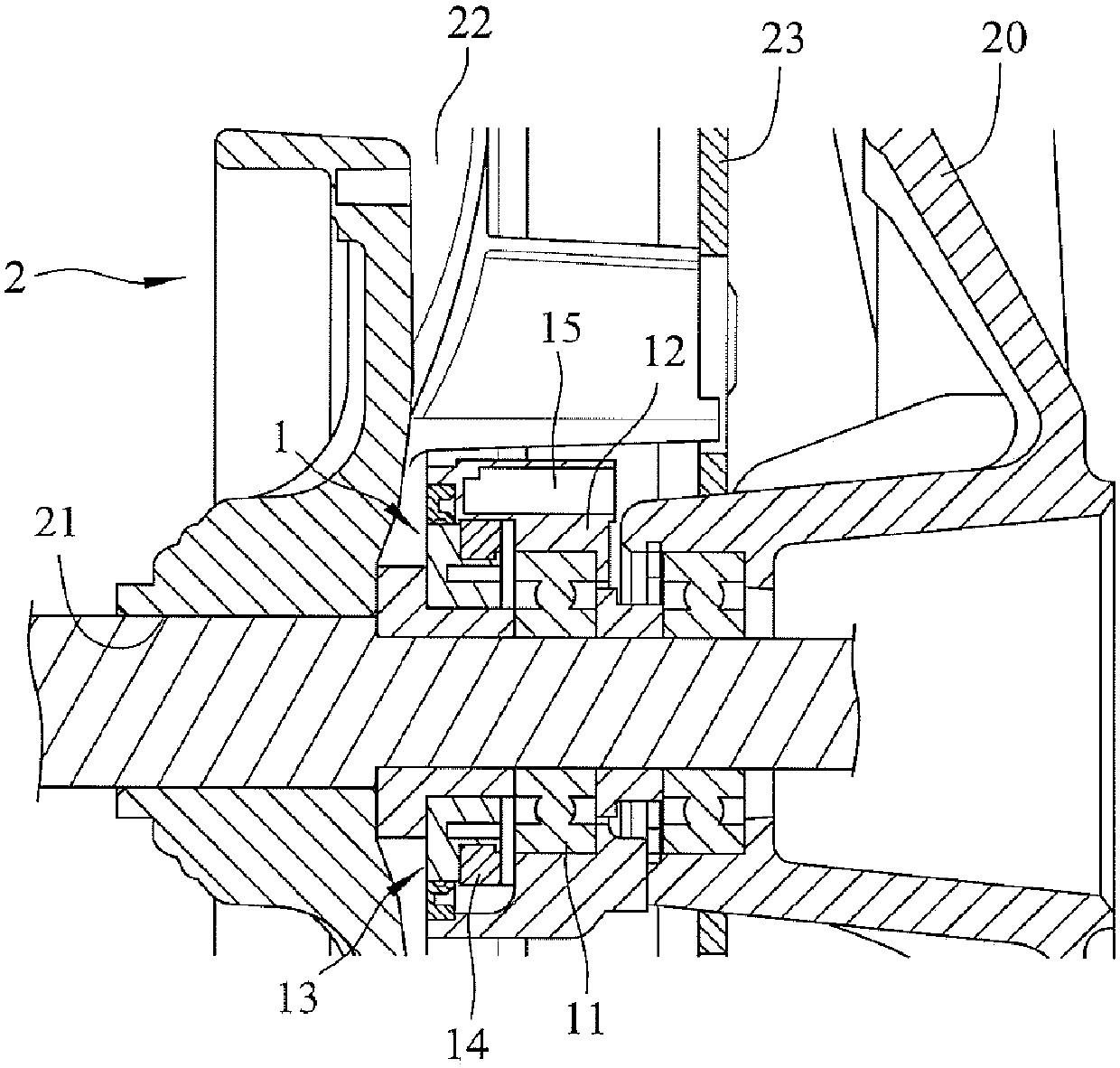

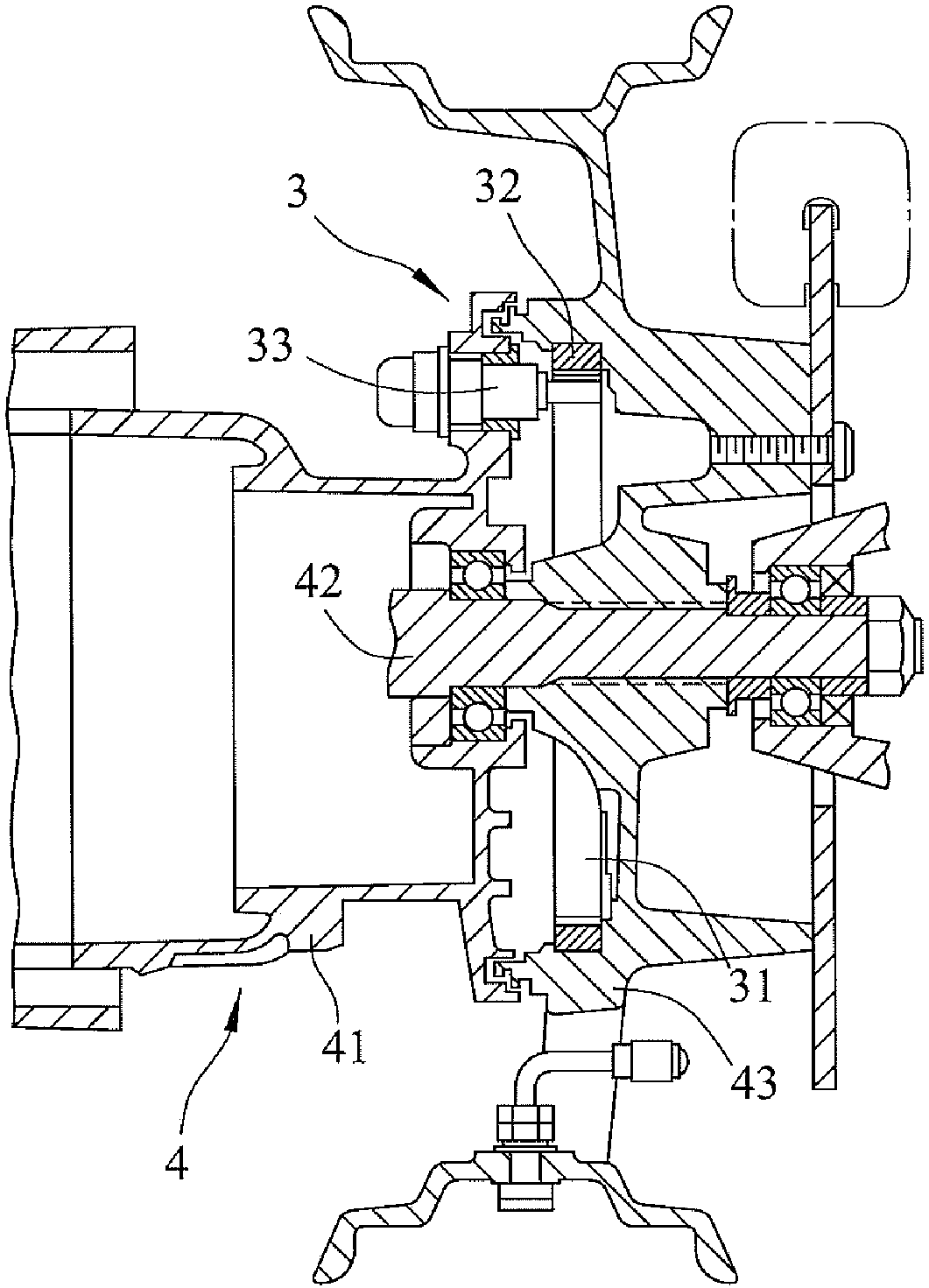

A technology for sensing device and vehicle speed, which is applied in vehicle components, transportation and packaging, rider driving, etc., and can solve the problem of inability to cooperate with the induction part 33, increase weight cost, and inability to miniaturize the components of the vehicle speed sensor 3 And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

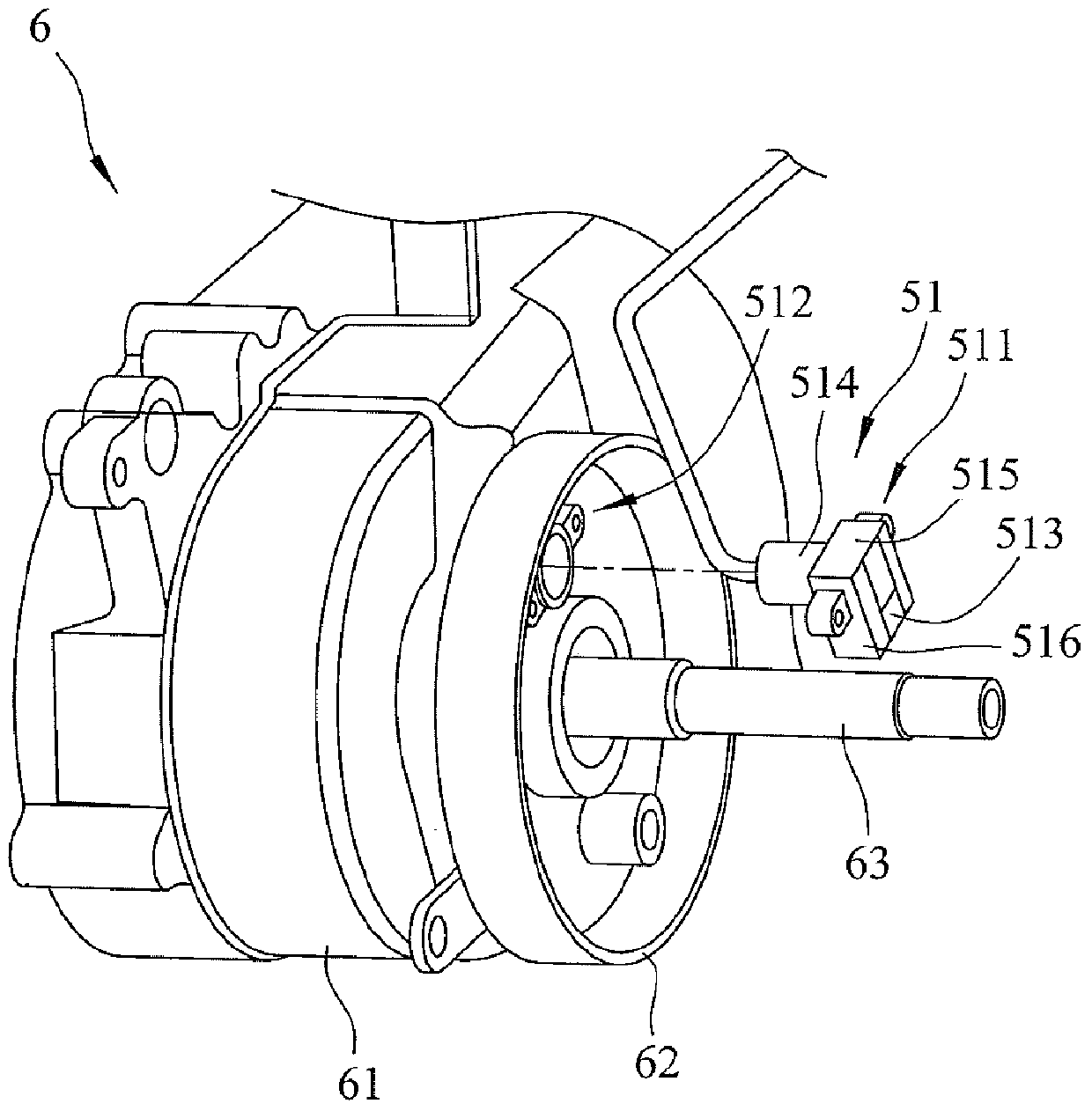

[0019] refer to Figure 3 to Figure 5 One embodiment of the vehicle speed sensing device 5 of the present invention is installed on a vehicle 6, and the vehicle 6 includes a transmission box 61, a surrounding wall 62 arranged on the transmission box 61, a pivotally mounted on the transmission box A rotating shaft 63 of 61, a rim 64 set on the rotating shaft 63, and a hub 65 arranged on the rim 64.

[0020] This embodiment includes a fixed measuring unit 51 installed on the transmission box 61 , and a rotating unit 52 installed on the rim 64 . Such as image 3 As shown, the fixed detection unit 51 includes a sensor 511, a sensor mounting portion 512 disposed within the surrounding range of the surrounding wall 62, and a sensing element 513 disposed on the sensor 511, The sensing element 513 is offset from the center of the sensor mounting portion 512 toward the center of the rotating shaft 63 . And as Figure 4 As shown, the rotating unit 52 includes a magnetic sensor 521 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com