A resistance-reducing technology mainly based on gas cushion resistance reduction

一种技术、气垫的技术,应用在减阻、舰艇、流体动力学特征/流体静力学特征等方向,能够解决没见有应用报道、限制鱼雷外形、重量与航程、使用的能量多等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

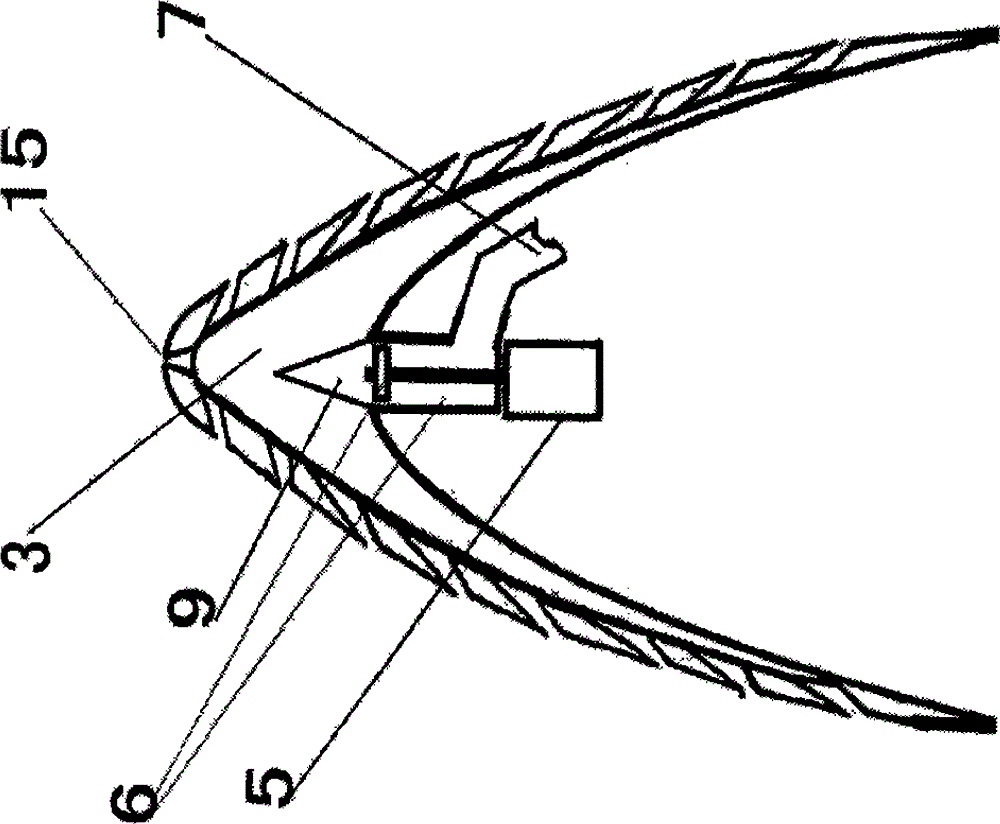

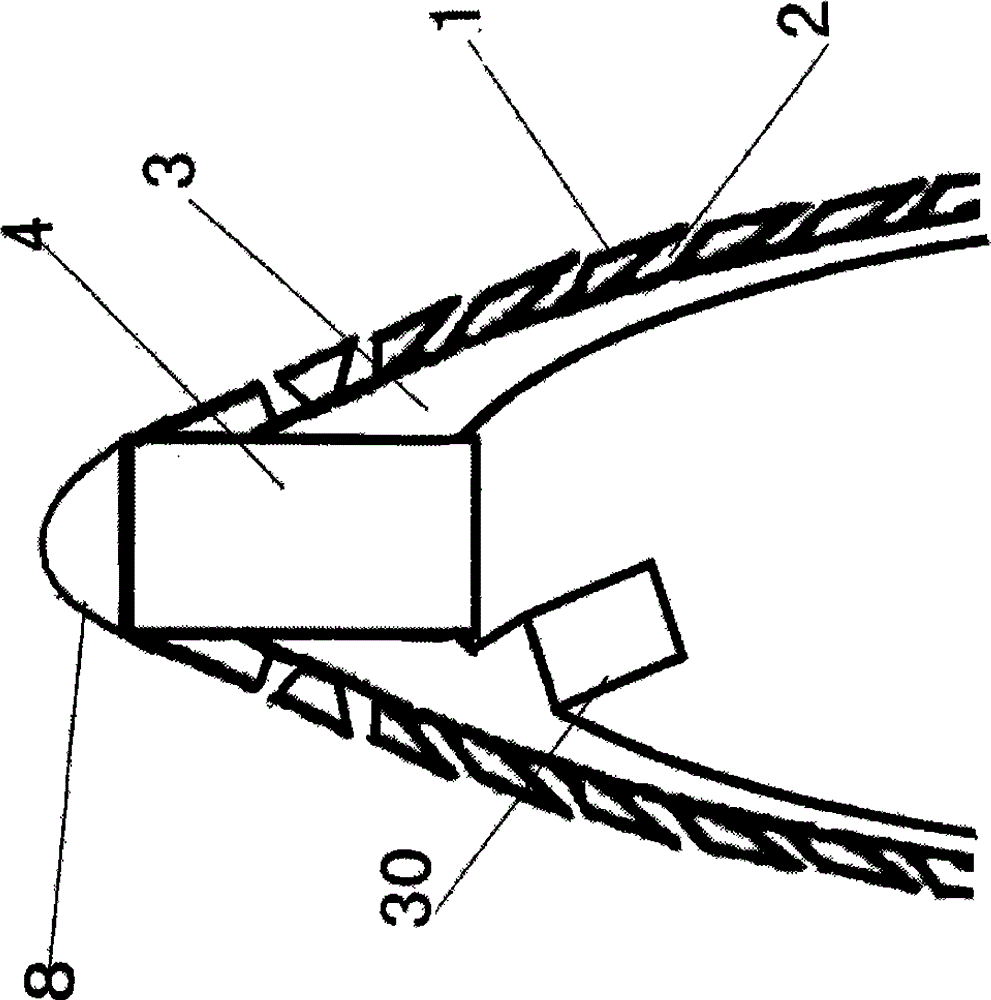

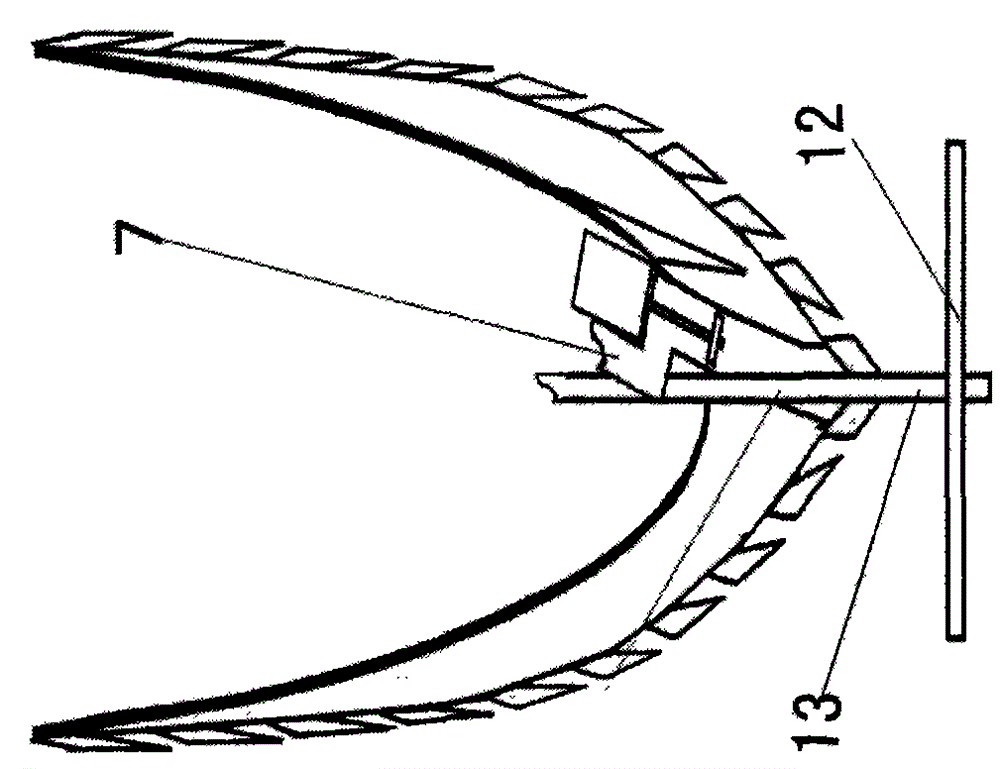

[0026] In various torpedoes, the entire outer surface of the front rectifying cone of a submarine, part or all of the outer surface of the rear of the cone, and the most forward surface of the part below the water surface line of various ships, as well as the rear or lower part of it Part or all of the surface, the installed jet-type drag-reducing jacket is provided with a gas-moving gap (2) jet-type drag-reducing jacket (1) shell layer on the outer surface; , and the rib-shaped support strips (3) between the outer surfaces of the ship; and the internal space of the drag-reducing coat between different rib-shaped support strips; installed in torpedoes, submarines, ships, and high-speed ships. To provide the air required for the work of the jet-type drag-reducing jacket, it can be composed mainly of a large-scale booster blower (6), or a high-temperature and high-pressure gas generation engine (30), or the main engine jet port.

[0027] When the jet-type drag-reducing jacket (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com