Double-layer columnar heat transfer device, pipeline for heat transfer of fluid substance and method

A columnar shell and columnar technology is applied in the fields of fluid material heat transfer pipes and double-layer columnar heat transfer devices, which can solve problems such as uneconomical, unsolved suggestions or solutions, and limited natural gas reserves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention are described below by means of drawings and specific embodiments.

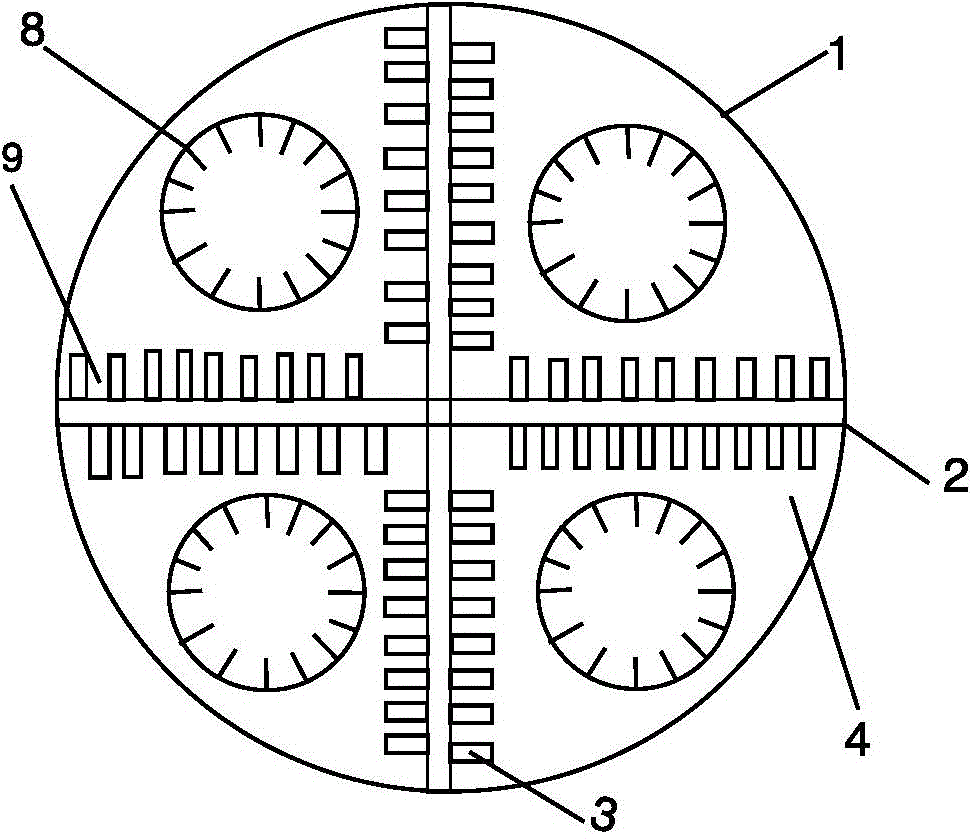

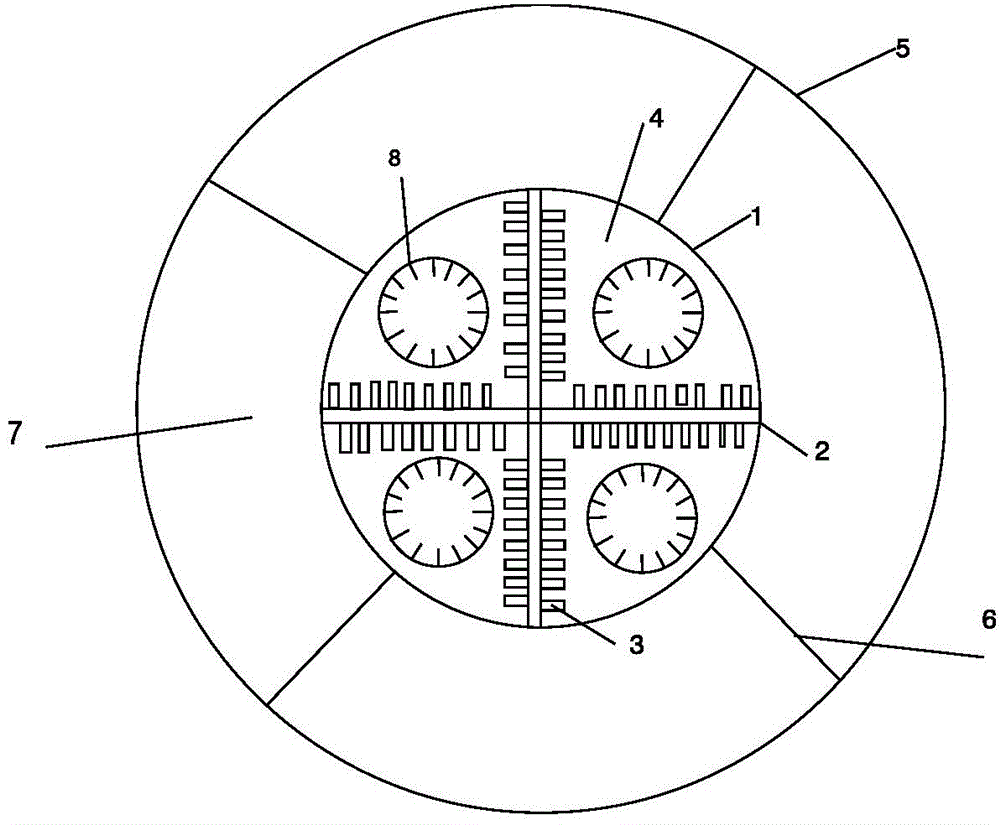

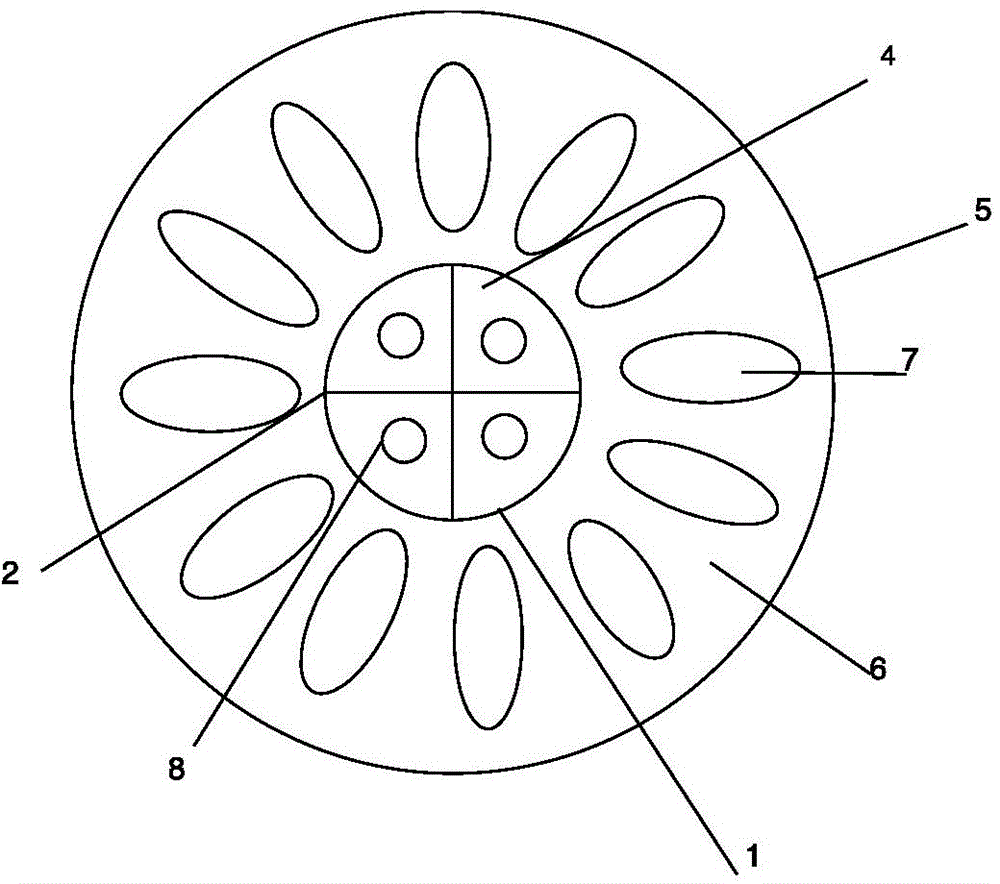

[0046] Such as figure 1 As shown, one of the most important aspects of the present invention is to provide a double-layer cylindrical heat transfer device, which is characterized in that: it includes a heat-conducting cylindrical shell 1 and a partition plate 2; the inner cavity of the heat-conducting cylindrical shell 1 It is a closed space; the partition plate 2 divides the inner cavity of the heat-conducting cylindrical shell 1 into a plurality of chambers 4 parallel to the axial direction of the heat-conducting cylindrical shell; Filled with working fluid; the inner wall of the chamber 4 is sequentially provided with a number of micro-fins 3 made of heat-conducting materials, and an array of capillary micro-grooves 9 is formed between adjacent micro-fins 3 . The fine grooves 9 are arranged in a way that is conducive to reducing the resistance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com