Mechanical lock with twin-core mutual control trap-type blade mechanism

A mechanical lock and blade technology, applied in the field of mechanical locks, can solve the problems of inability to prevent technical unlocking or violent unlocking, inability to fall completely, and inability to release the locking body of the lock, so as to prevent technical unlocking and improve security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

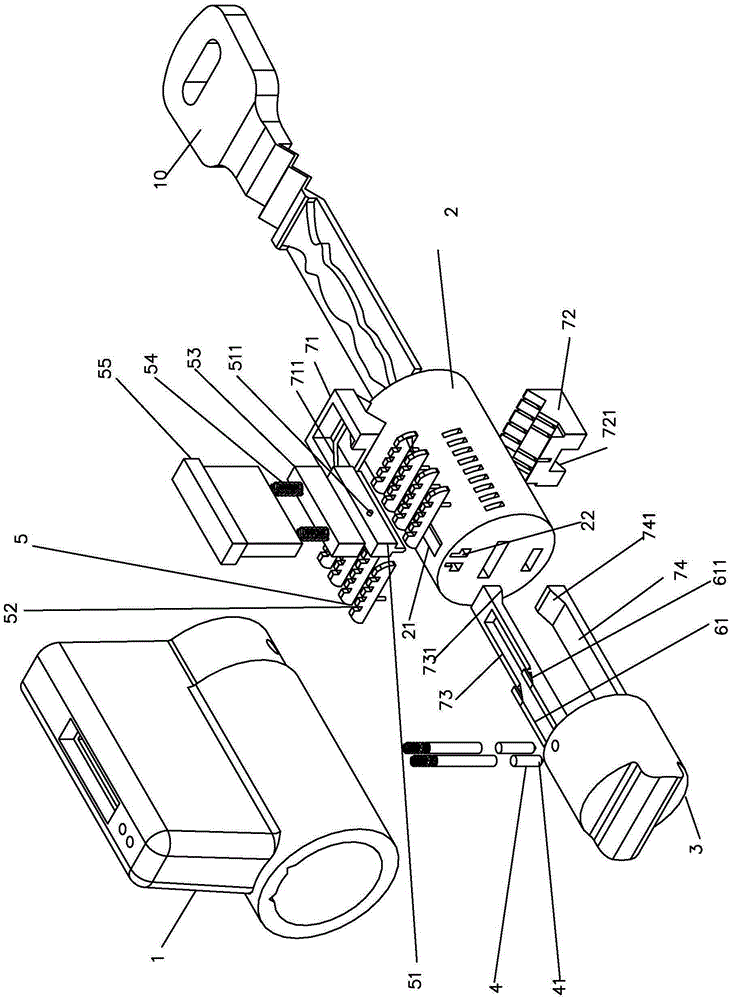

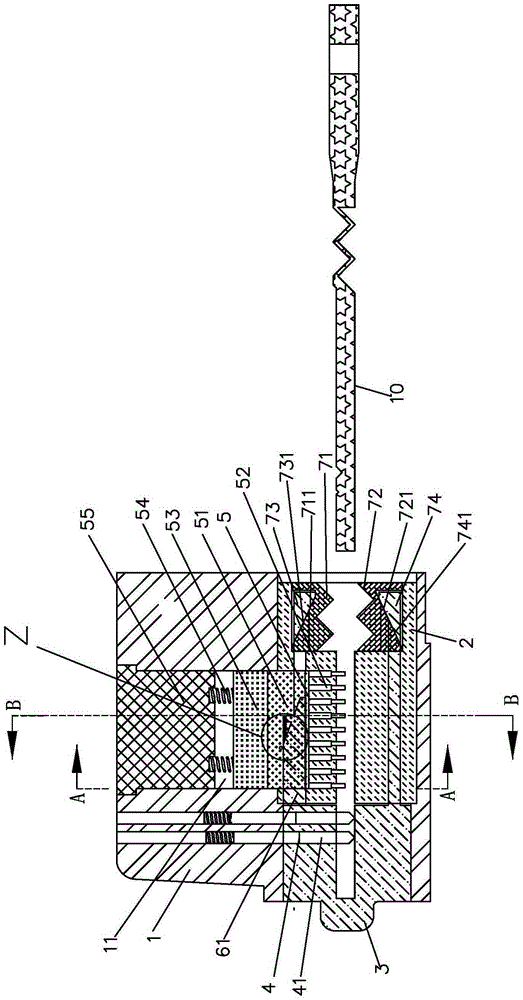

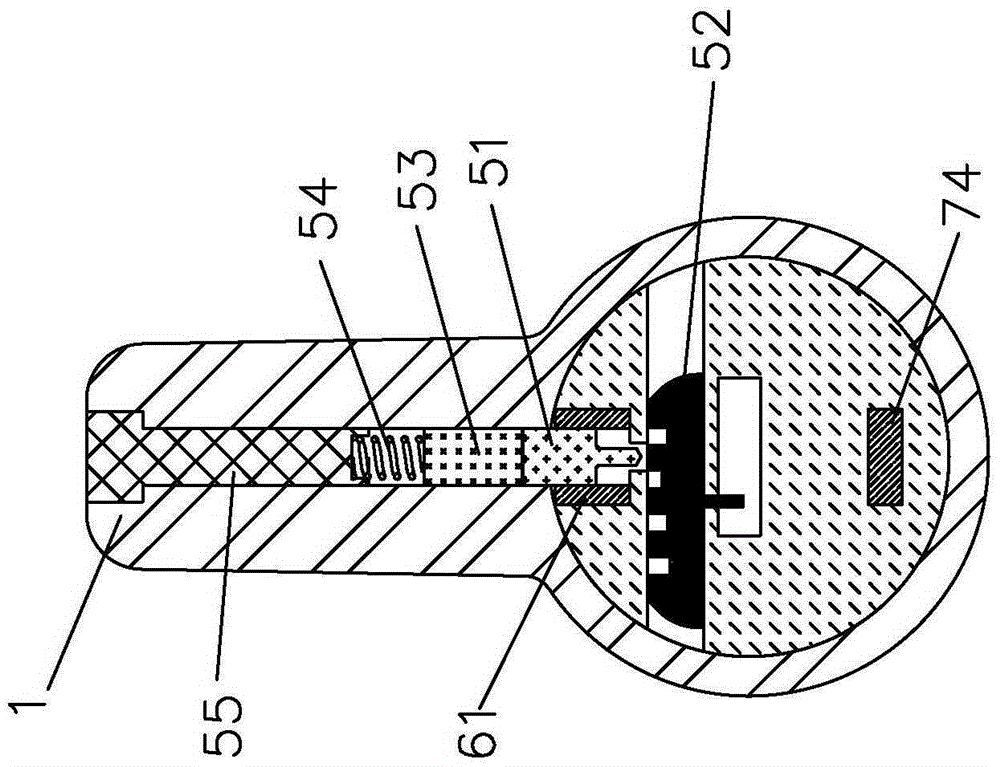

[0057] see Figure 1 to Figure 28 As shown, a mechanical lock of a dual-core mutual control trap-type blade mechanism of the present invention includes a lock head and a key 10; the lock head includes a lock head body 1, a front lock cylinder 2 and a rear lock cylinder 3; the front lock cylinder 1. The rear lock core is rotatably installed in the lock head body, and the rear lock core 3 can also move axially; the front lock core, the rear lock core and the lock head body are respectively equipped with a front locking mechanism 5 that can be decoded by a key 10 , the rear locking mechanism 4; the front locking mechanism 5 is a blade mechanism, the blade mechanism includes a tumbler 51 and a plurality of blades 52 for matching with the convex portion 512 at the bottom of the tumbler, and the blade 52 is provided with a plurality of blades Slot 521, in a plurality of blade grooves 521, only one blade groove 521 is the combination groove, and other blade grooves 521 are all trap g...

Embodiment 2

[0080] see Figure 29 As shown, the mechanical lock of a dual-core mutual control trap-type blade mechanism of the present invention is different from Embodiment 1 in that the rear locking mechanism 4 between the rear lock cylinder and the lock head body is a blade mechanism 42 , the blade mechanism 42 is installed between the rear lock core 3 and the lock body 1 in the radial direction to limit the rotation and axial movement of the rear lock core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com