Automatic feeding trough device for pig farm

A technology for automatic feeding and pig farms, applied in animal feeding devices, animal drinking devices, applications, etc., can solve problems such as high labor intensity, deteriorated food, and inconvenient pig licking, so as to ensure scientific growth, The effect of reducing feed waste and avoiding enteric diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the technical solution of the present invention, the technical content thereof will be further described below in conjunction with the accompanying drawings and embodiments.

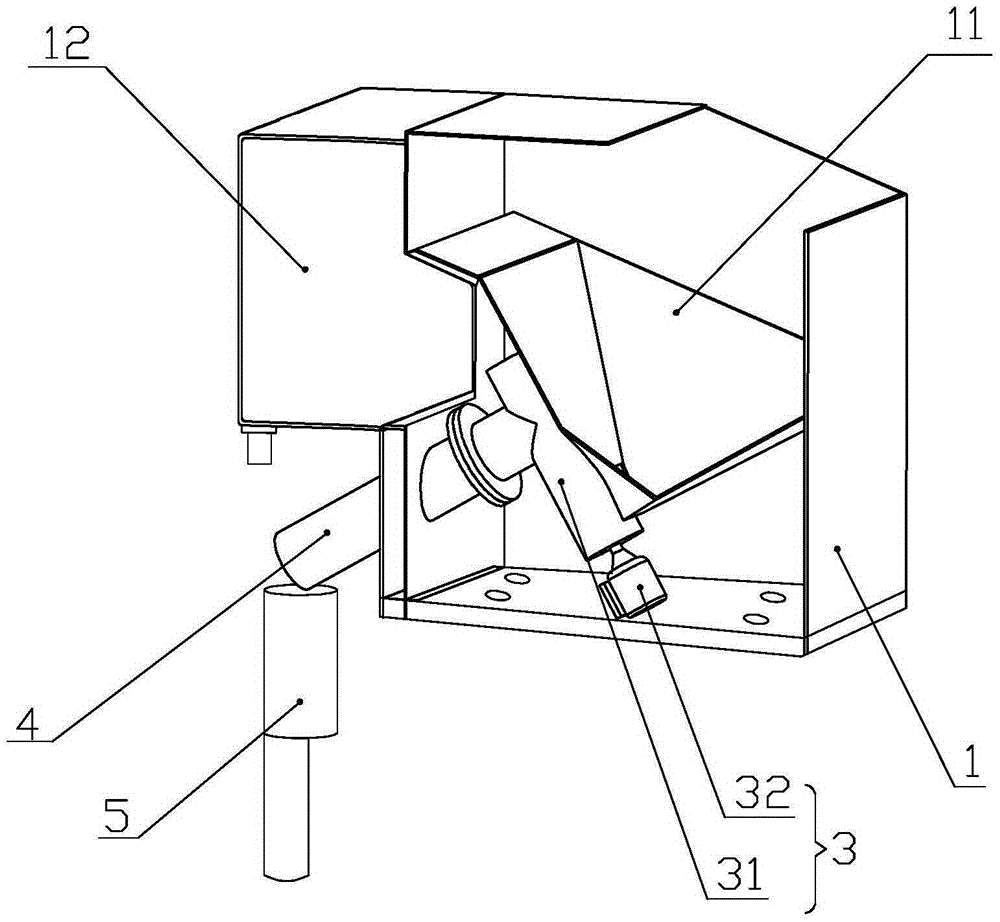

[0023] Such as figure 1 , figure 2 A pig farm automatic feeding trough device as shown:

[0024] It includes a material storage box 1, a food trough 2, a Jiaolong conveying unit 3 and a material guide pipe.

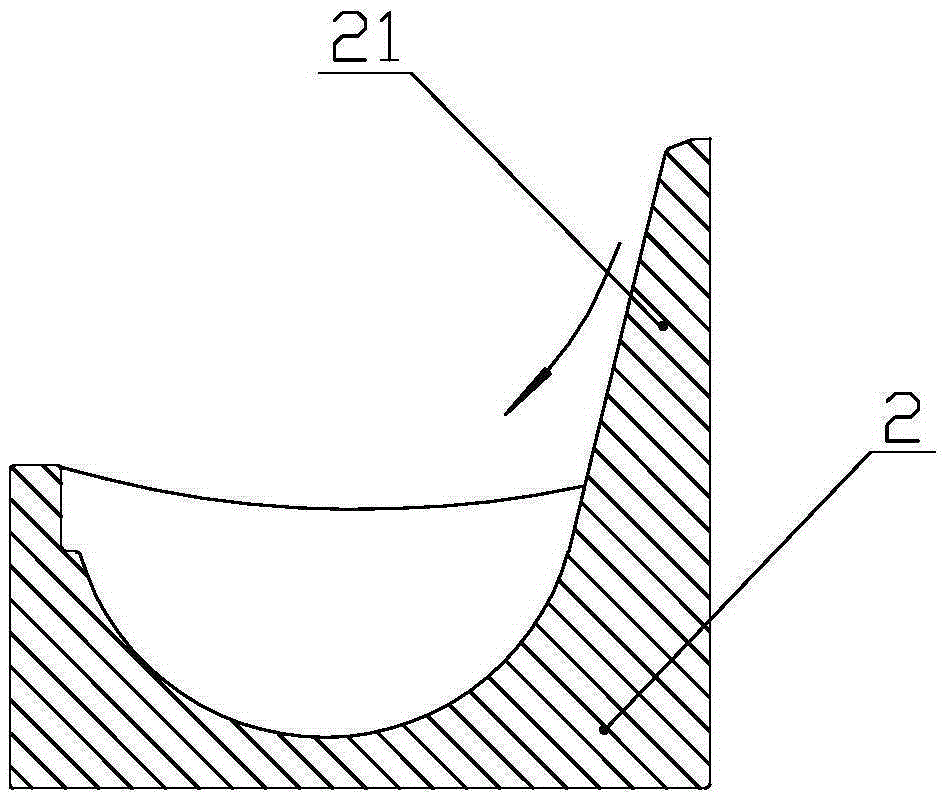

[0025] The material storage box 1 is provided with a conical bin 11 . The cavity of the food trough 2 is a semicircular cavity, and a material guide plate 21 is arranged on one side, so that the inner end surface of the material guide plate 21 is obliquely arranged and tangent to the semicircular cavity.

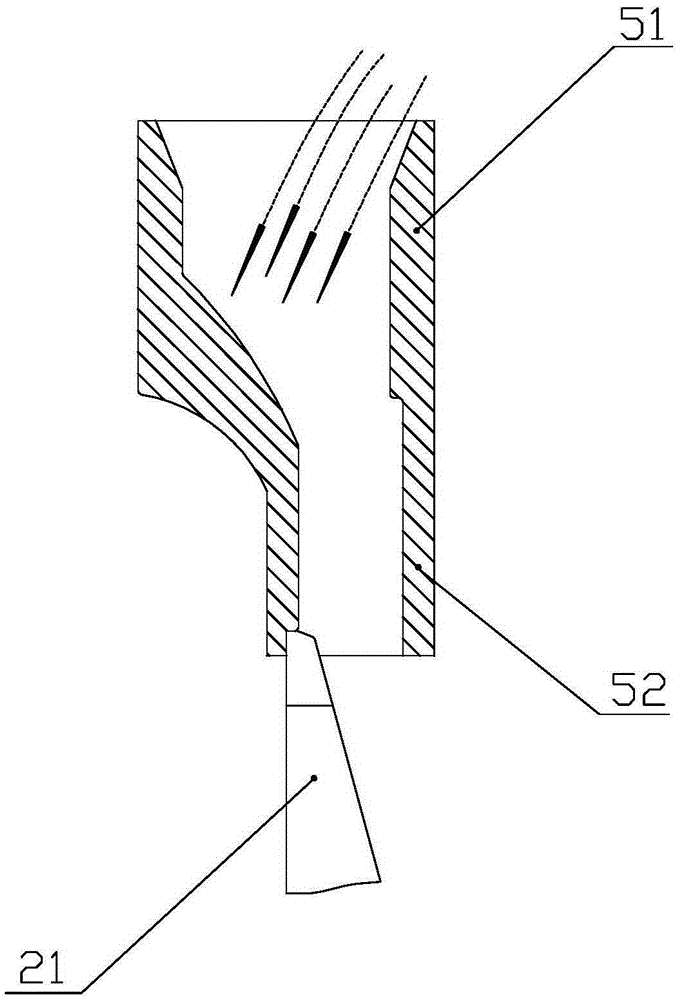

[0026] The dragon conveying unit 3 includes a cylindrical dragon body 31 and a drive motor 32 , the dragon body 31 is obliquely arranged below the conical bin 11 (axially), and the drive motor 32 is installed at the lower end of the dragon bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com