Cotton cutting roller for fully automatic cotton cutting machine

A fully automatic cotton cutting machine technology, applied in fiber cutting, textile and paper making, fiber processing, etc., can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

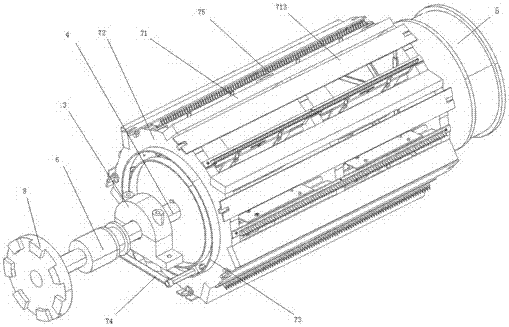

[0026] The invention provides a cotton cutting cylinder for a fully automatic cotton cutting machine. This application redesigns the cotton cutting cylinder of the cotton cutting machine. Using the cotton cutting cylinder in conjunction with a corresponding cotton cutting machine can greatly improve the automation of the entire cotton cutting operation. Intensity, in order to achieve the purpose of reducing labor.

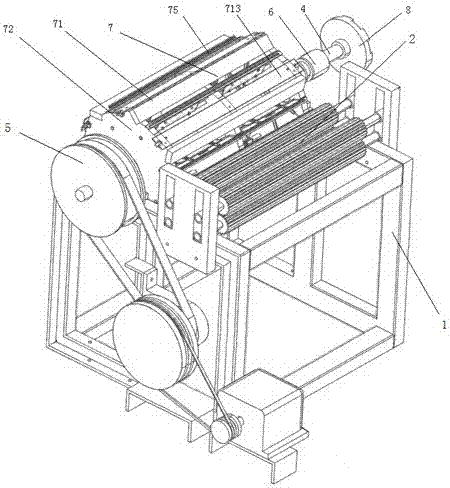

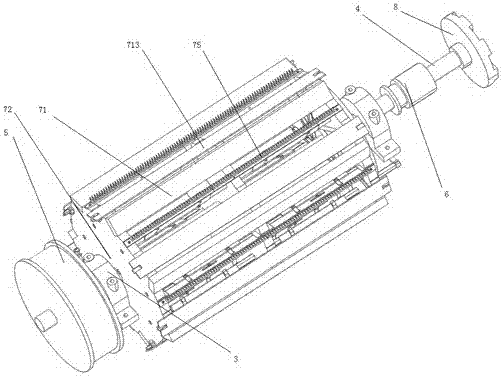

[0027] As an embodiment of the present invention, the present invention provides such as figure 1 Shown is a cotton cutting roller for a fully automatic cotton cutting machine, the main body of the cotton cutting roller 7 is behind the roller 2 of the main body of the cotton cutting machine 1, and the cotton cutting roller is fixed to the two rollers of the main body of the cotton cutting machine through the rotating shafts at both ends Between the fixed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com