A multi-layer bolted ball joint used in a tensegrity structure

A technique for tensioning the overall structure and bolt balls, applied in the direction of building structure, construction, etc., can solve the problems of the influence of the scope of use and the complexity of the tensioning process, and achieve the effects of easy on-site control, convenient construction and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The multi-layer bolt ball joints used in the tensegrity structure provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

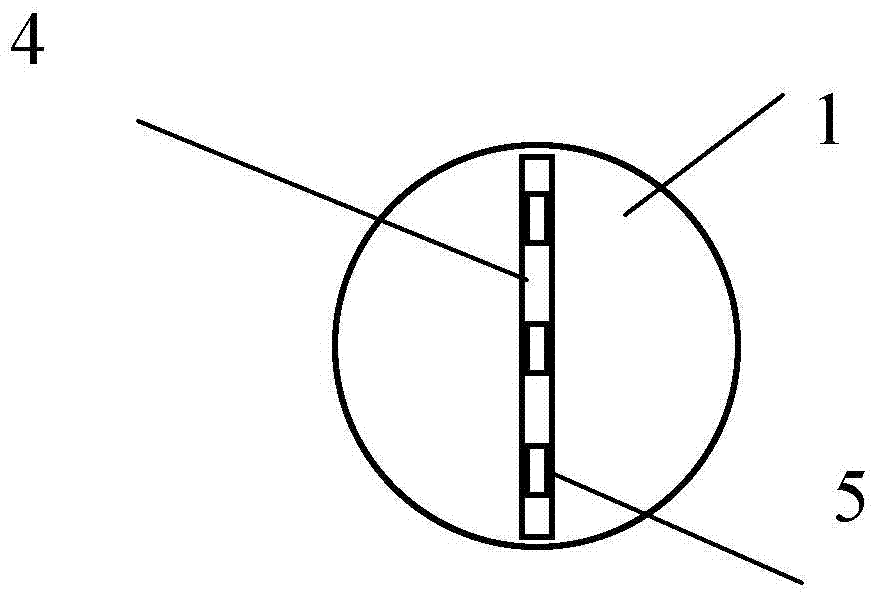

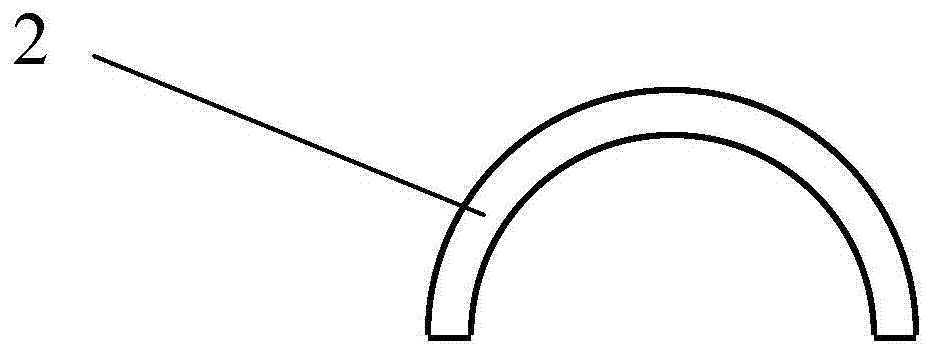

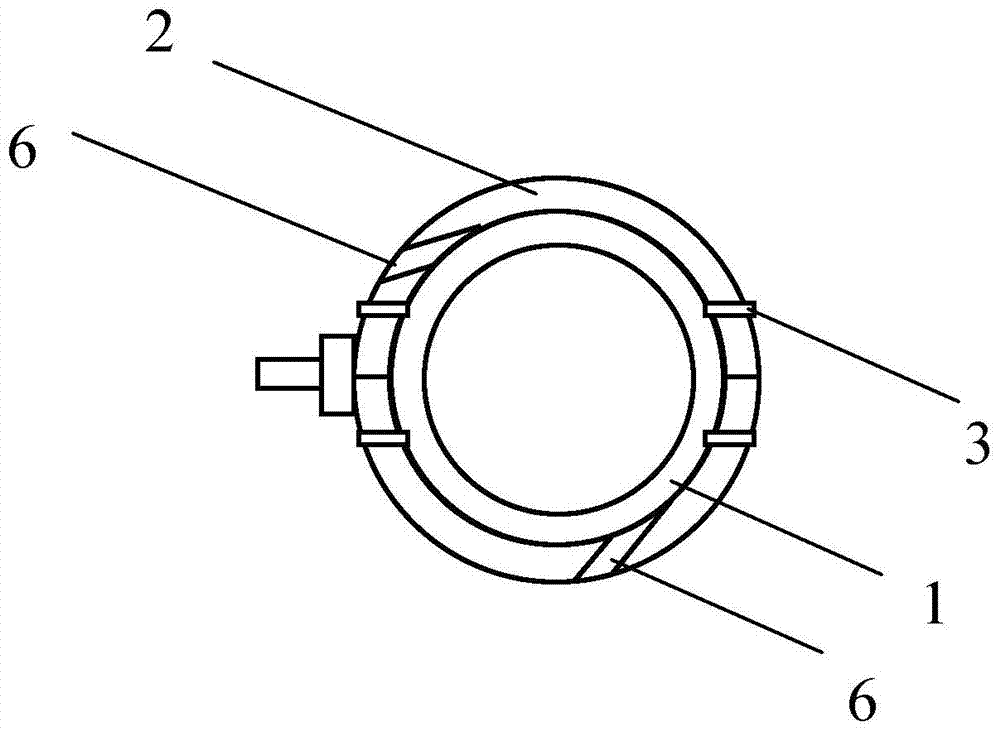

[0014] like figure 1 — image 3 As shown, the multi-layer bolted ball node used in the tensegrity structure provided by the present invention includes an inner bolted ball 1, a plurality of outer bolted hemispheres 2, a plurality of connecting bolts 3 and a plurality of rolling bearings 5; wherein the outer bolted ball of the inner bolted ball 1 An arc-shaped groove 4 is arranged on the circumferential surface, and a plurality of rolling bearings 5 are arranged in the groove 4 at intervals; the outer bolt hemisphere 2 is a shell-like structure, and each outer bolt hemisphere 2 is provided with a 1 The cable hole 6 corresponding to the position of the upper groove 4; the outside of the inner bolt ball 1 is at least covered with an outer layer composed of two outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com