Liquid crystal display device

一种液晶显示装置、选择反射的技术,应用在光学、仪器、非线性光学等方向,能够解决部件结构复杂等问题,达到改善正面亮度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

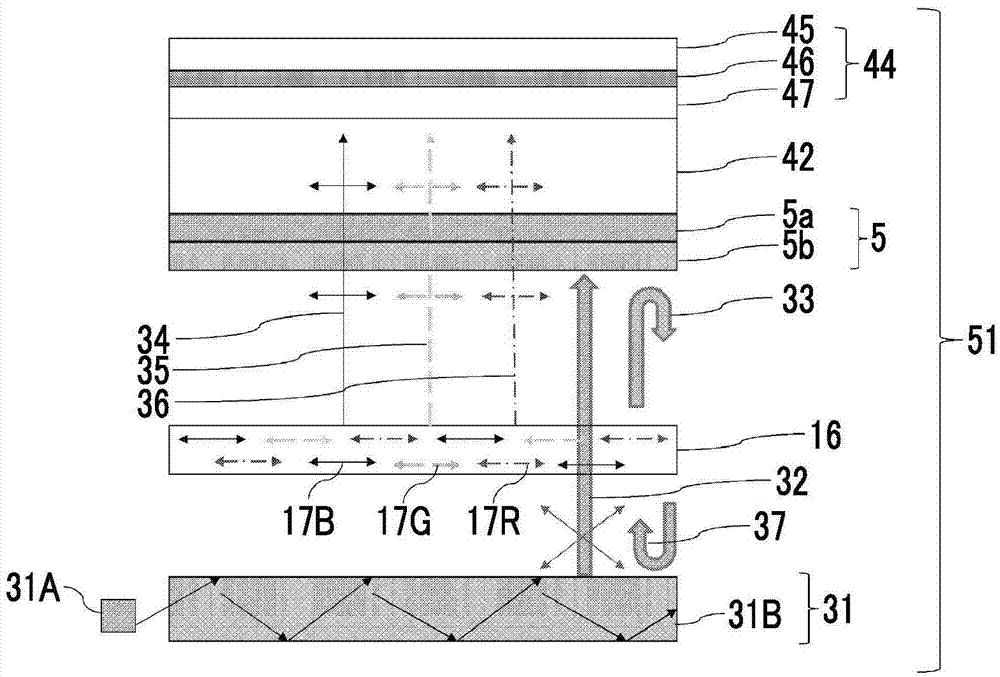

Embodiment 1

[0254]

[0255] A commercially available cellulose acylate film "TD60" (manufactured by FUJIFILM Corporation) was used as the front side polarizing plate protective film of the backlight side polarizing plate.

[0256] A cellulose acylate-based film "TD60" (manufactured by FUJIFILM Corporation) was used as the rear polarizing plate protective film of the backlight side polarizing plate.

[0257] The same method as [0219] to [0220] of Japanese Patent Laid-Open No. 2006-293275 is used to manufacture a polarizer, and the above two polarizer protective films are attached to both sides of the polarizer respectively to manufacture a polarizer 1 .

[0258]

[0259] (Formation of dielectric multilayer film)

[0260] Referring to IDW / AD'12, p.985~988 (2012), the total thickness is changed to 5 μm so that the reflection center wavelength corresponding to the peak of the maximum reflectance in the wavelength range of UV light becomes 365 nm and the half width is 30 nm, To manufactu...

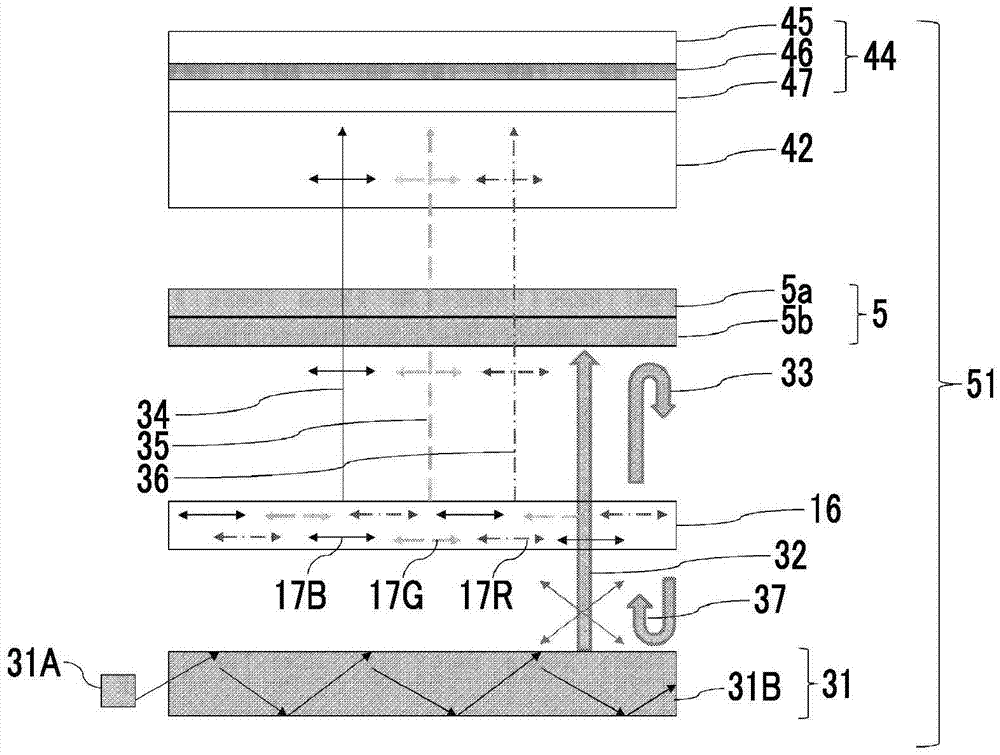

Embodiment 2

[0274]

[0275] Referring to IDW / AD'12, p.985-988 (2012), except that the total thickness was changed to 3 μm, a dielectric multilayer Layer 2-B. A dielectric multilayer film 1-B was formed by the same method as that of the dielectric multilayer film 1-A used in Example 1.

[0276] On the polarizing plate 1 , a UV reflective dielectric multilayer film 2 -B and a UV reflective dielectric multilayer film 1 -B were bonded sequentially in the same manner as in Example 1.

[0277] In Example 1, except that the UV reflective dielectric multilayer films 2-B and 1-B formed above are arranged instead of the polarizing plate 1 having the UV reflective dielectric multilayer films 2-A and 1-A arranged on the rear side. Except for the polarizing plate 1 on the rear side, the liquid crystal display device of Example 2 was produced in the same manner as in Example 1.

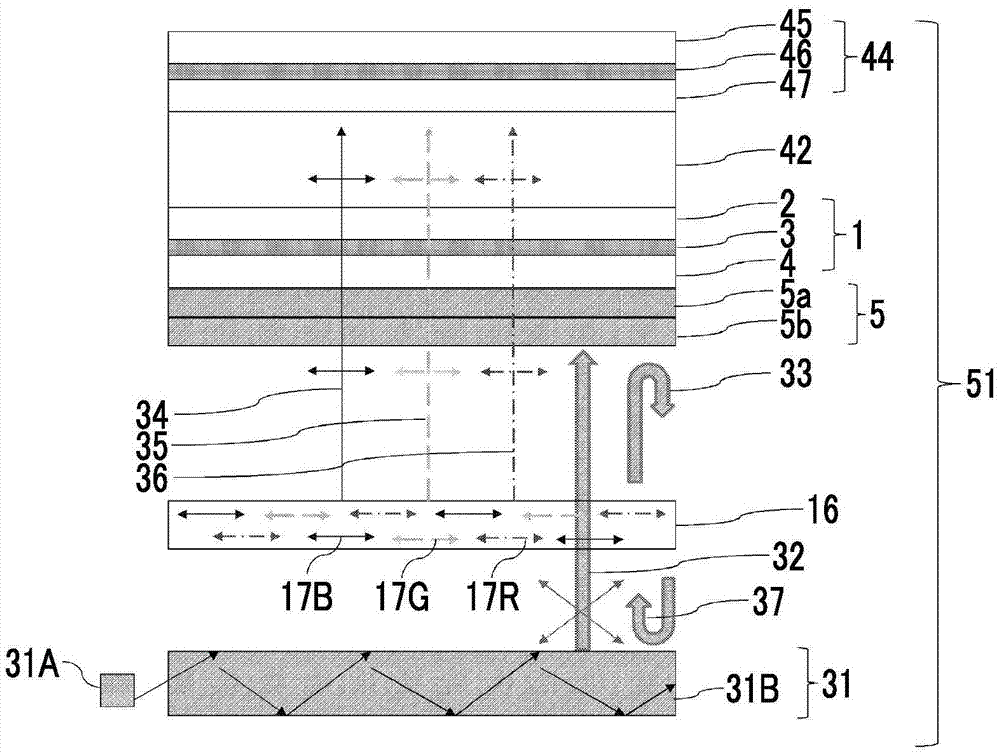

Embodiment 3

[0279]

[0280] (Formation of light reflection layer fixed by cholesteric liquid crystal phase)

[0281] On the support, refer to FUJIFILM Research Report No.50 (2005) pp.60-63, change the amount of chiral agent added, and form by coating a light reflection layer fixed by a cholesteric liquid crystal phase 1 story. The obtained light reflection layer in which the cholesteric liquid crystal phase was immobilized was referred to as UV reflection CLC1 (left-handed circularly polarized light reflection).

[0282] In the UV reflection CLC1 (left-handed circularly polarized light reflection), in addition to changing the type of chiral agent used to form a left-helical cholesteric liquid crystal structure, the formation of the UV reflection CLC1 (left-handed circularly polarized light reflection) In the same manner, one layer was formed by applying a light reflection layer fixed with a cholesteric liquid crystal phase. The obtained light reflection layer in which the cholesteric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com