Non-destructive self-shedding mussel harvesting system

A self-shedding and mussel technology, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of mussel shell rupture, mussel meat pressure loss, and mussel damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

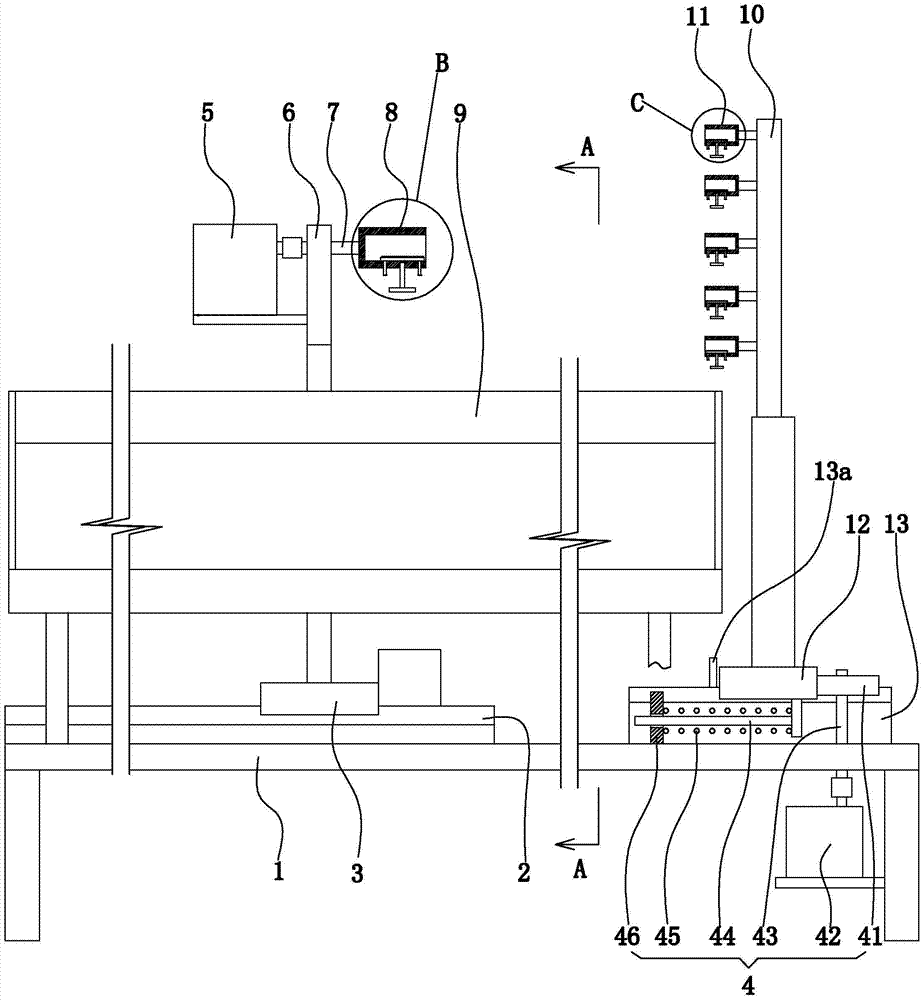

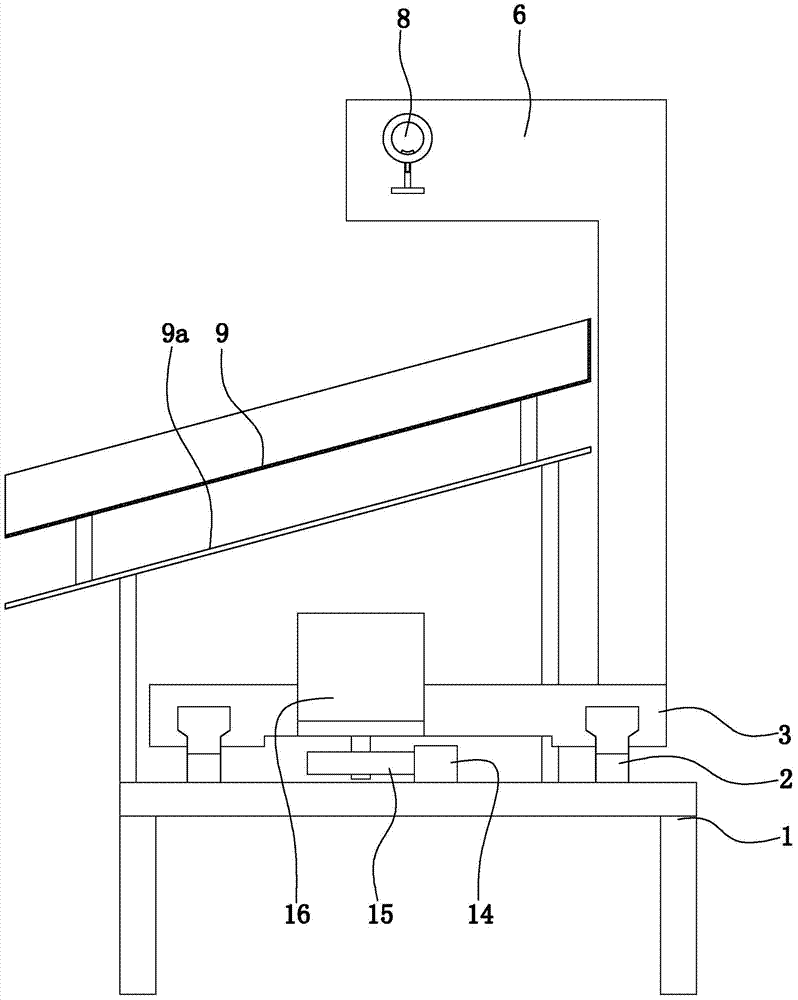

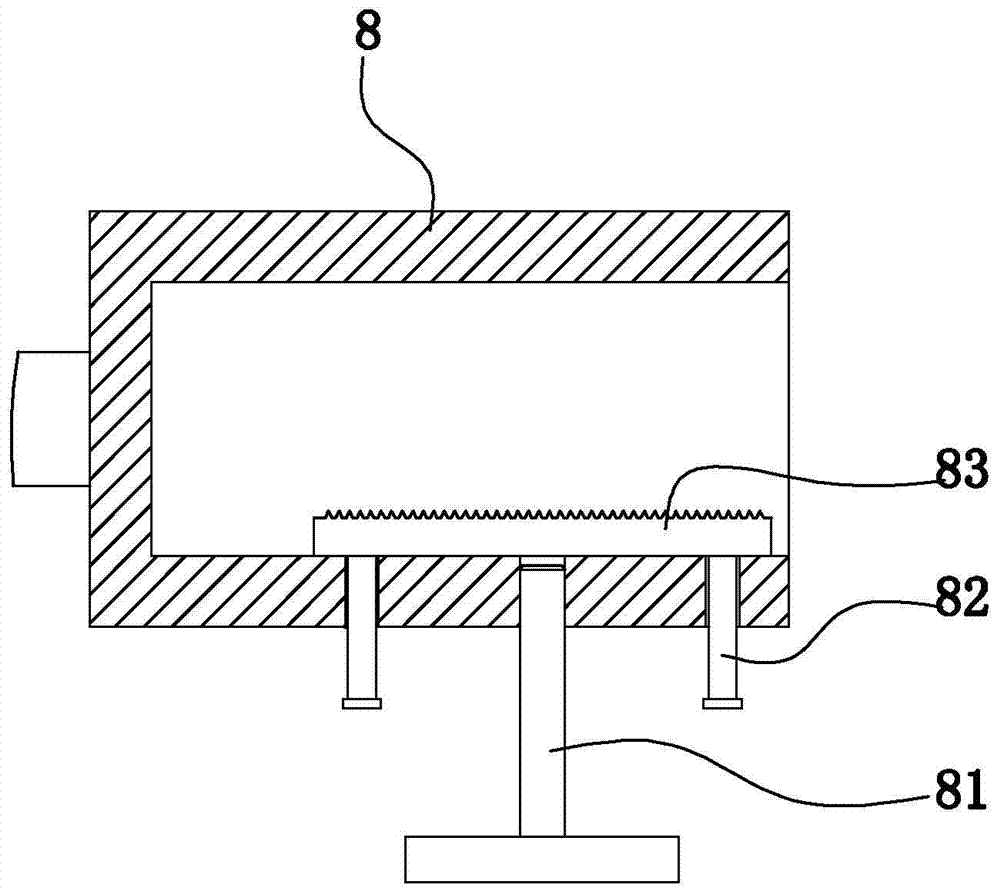

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] Such as figure 1 , Figure 5 , Figure 6 As shown, a non-destructive self-falling mussel picking system includes a culture rope 17, a frame 1 and a self-falling removal device arranged on the frame. The culture rope includes a load-bearing core rope 171 and several attachment ropes 172 wound in parallel outside the load-bearing core rope. The outer diameter of the load-bearing core rope is greater than twice the outer diameter of the attachment rope. There are ten attachment ropes in this embodiment. The outer diameter of the attachment rope is less than 10 millimeters, and the outer diameter of the attachment rope in this embodiment is 8 millimeters. Each attachment rope is wound clockwise on the load-bearing core rope. A hoop 173 is sheathed at both ends of the breeding rope respectively. The hoop tightens each attached rope on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com